Reactive dye and preparation method thereof

A technology of reactive dyes and alkaline solutions, which is applied in the field of leather dyeing, can solve the problems that reactive dyes are difficult to apply to leather dyeing, and achieve the effects of improving the utilization rate of dyes, improving color fastness, and reducing the concentration of residual dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

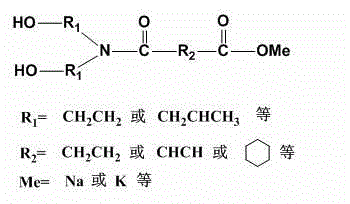

Method used

Image

Examples

Embodiment 1

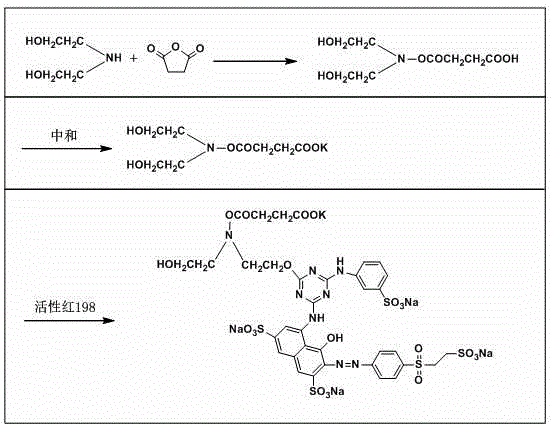

[0018] Take by weighing 13.32g diisopropanolamine and add the four-necked bottle, slowly warming up to 80 o C, then 9.8g of maleic anhydride was dissolved in 100 mL of dimethylformamide, slowly dropped into a four-neck flask, at 80 o C reaction 6h, cool down to 60 o C, use 30% NaOH solution to slowly neutralize to pH 9, then distill off dimethylformamide under reduced pressure to obtain hydroxyamide carboxylate.

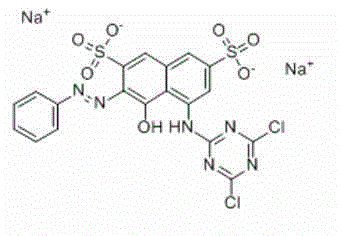

[0019] After 44.75g active bright yellow K-4G is dissolved in 800g water, add in the above-mentioned hydroxyamide carboxylate of 25.3g, 80 o C reacted for 2 hours, after drying and grinding, a carboxyl yellow modified reactive dye was obtained. Among them, the molecular structural formula of Active Bright Yellow K-4G is:

[0020]

Embodiment 2

[0022] Take by weighing 13.32g diisopropanolamine and add the four-necked bottle, slowly warming up to 80 o C, then 9.8g of maleic anhydride was dissolved in 100 mL of dimethylformamide, slowly dropped into a four-neck flask, at 40 o C reaction 48h, cooling to 60 o C, use 30% NaOH solution to slowly neutralize to pH 9, then distill off dimethylformamide under reduced pressure to obtain hydroxyamide carboxylate.

[0023] After dissolving 22.4g active bright yellow K-4G in 400g water, add in the above-mentioned hydroxyamide carboxylate of 25.3g, 60 o C reacted for 4 hours, and after drying and grinding, a carboxyl yellow modified reactive dye was obtained.

Embodiment 3

[0025] Take by weighing 10.5g diethanolamine and add four-necked bottle, slowly warming up to 80 o C, then dissolve 10g of succinic anhydride in 100 mL of dimethylacetamide, slowly drop it into a four-neck flask, at 90 o C reaction 1h, cooling to 60 o C. Slowly neutralize to pH9 with 30% KOH solution, then distill off dimethylacetamide under reduced pressure to obtain hydroxyamide carboxylate.

[0026] After dissolving 61.5g reactive brilliant red X-3B in 615g water, add 22.7g of the above-mentioned hydroxyamide carboxylate, 95 o C reacted for 1h, after drying and grinding, a carboxyl red modified reactive dye was obtained. Among them, the molecular structural formula of Reactive Brilliant Red X-3B is:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com