Rib heating fiber fabric

A heat-generating fiber and fabric technology, applied in fabric surface trimming, heating/cooling fabric, textile, etc., can solve the problems of poor thermal performance and affect the feeling of use, achieve soft hand feeling, increase dyeing speed, and reduce dye content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

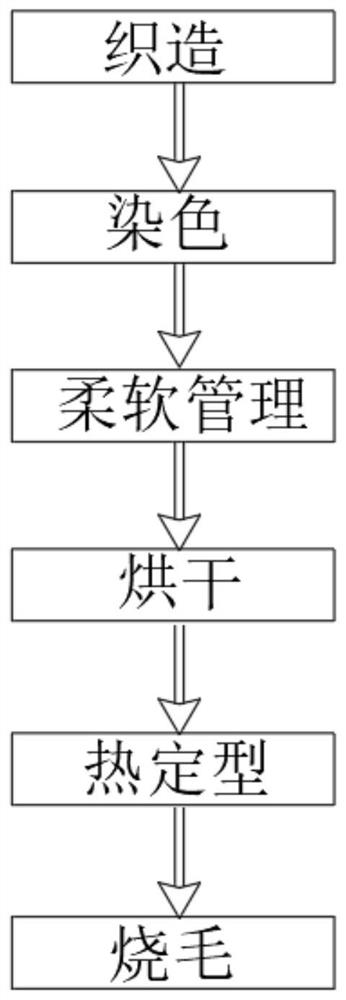

[0032] refer to figure 1 , a kind of rib heating fiber fabric, its preparation method comprises the following steps:

[0033] S1: weaving, select the appropriate yarn to weave the fabric;

[0034] S2: Dyeing, putting the woven fabric into the dyeing house for dyeing;

[0035] S3: Soft finishing, using the process of dipping and rolling to soften the fabric;

[0036] S4: Drying, first wring out the moisture in the cloth, and then put the cloth in the drying cylinder for drying;

[0037] S5: heat setting, after the fabric is heat-treated for a period of time, it is cooled rapidly to make it shape;

[0038] S6: Singeing, burning off the excess threads on the fabric after the setting is completed.

[0039] In particular, in S1 of the present invention, 30 lbs of blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber are selected as the warp yarn, and the blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber is selected. Spinning coun...

Embodiment 2

[0042] refer to figure 1 , a kind of rib heating fiber fabric, its preparation method comprises the following steps:

[0043] S1: weaving, select the appropriate yarn to weave the fabric;

[0044] S2: Dyeing, putting the woven fabric into the dyeing house for dyeing;

[0045] S3: Soft finishing, using the process of dipping and rolling to soften the fabric;

[0046] S4: Drying, first wring out the moisture in the cloth, and then put the cloth in the drying cylinder for drying;

[0047] S5: heat setting, after the fabric is heat-treated for a period of time, it is cooled rapidly to make it shape;

[0048] S6: Singeing, burning off the excess threads on the fabric after the setting is completed.

[0049] In particular, in S1 of the present invention, 30 lbs of blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber are selected as the warp yarn, and the blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber is selected. Spinning count ...

Embodiment 3

[0052] refer to figure 1 , a kind of rib heating fiber fabric, its preparation method comprises the following steps:

[0053] S1: weaving, select the appropriate yarn to weave the fabric;

[0054] S2: Dyeing, putting the woven fabric into the dyeing house for dyeing;

[0055] S3: Soft finishing, using the process of dipping and rolling to soften the fabric;

[0056] S4: Drying, first wring out the moisture in the cloth, and then put the cloth in the drying cylinder for drying;

[0057] S5: heat setting, after the fabric is heat-treated for a period of time, it is cooled rapidly to make it shape;

[0058] S6: Singeing, burning off the excess threads on the fabric after the setting is completed.

[0059] In particular, in S1 of the present invention, 30 lbs of blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber are selected as the warp yarn, and the blended yarn of 30% kapok fiber and 70% soft silk protein regenerated fiber is selected. Spinning coun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com