Power saving highl luminance integrated fluorescent lamp

An integrated technology for discharge lamps, applied in the field of integrated fluorescent lamps, can solve the problems of inability to clearly distinguish luminescence and ionization, etc., and achieve the effects of improving heat retention, solving power consumption problems, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] Hereinafter, embodiments of the integrated fluorescent lamp of the present invention will be described in detail with reference to the drawings.

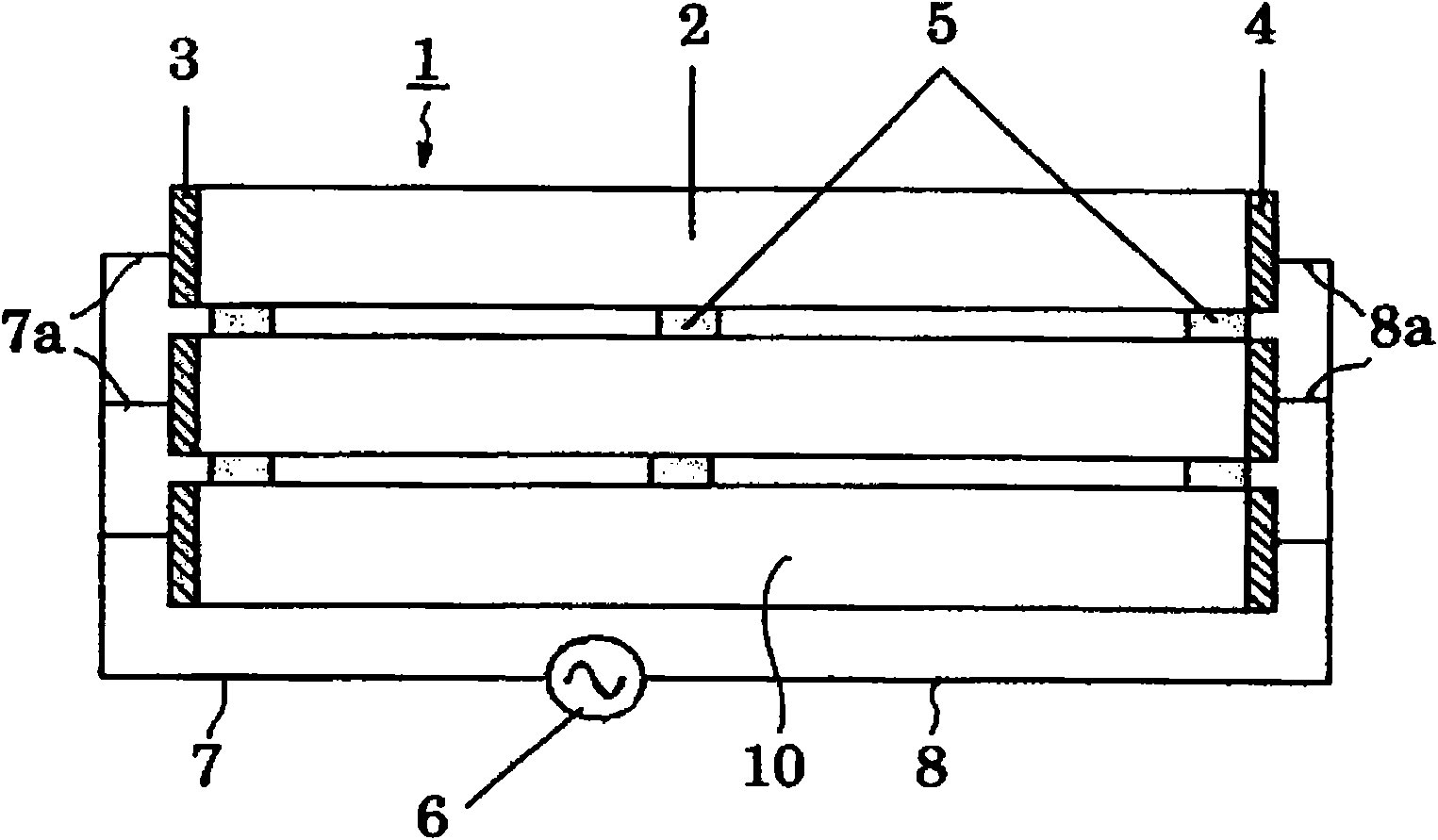

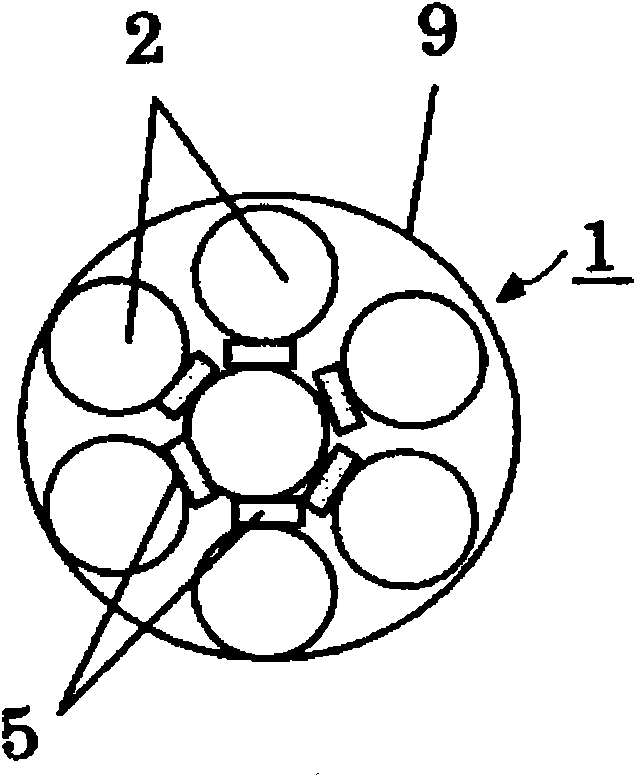

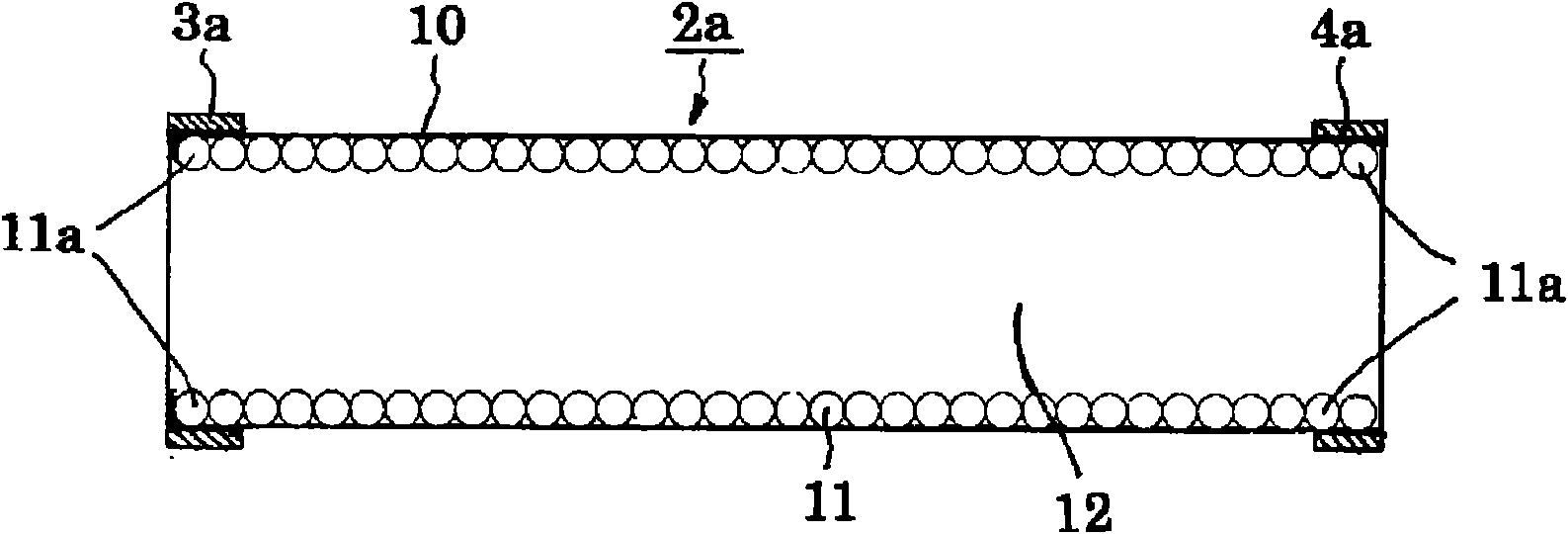

[0159] figure 1 It is an overall configuration diagram of the integrated fluorescent discharge lamp of the present invention in which seven fluorescent lamp tubes of the same tube diameter are bundled. In this integrated fluorescent lamp 1 , six fluorescent lamp tubes 2 are separated from each other by a predetermined interval through a spacer 5 and arranged in a bundle. Discharge space insulating electrodes 3 and 4 are formed on the left and right ends of the above-mentioned fluorescent lamp tube 2 . The discharge space insulating electrodes 3 and 4 are electrically insulated from the discharge space 10 formed inside the fluorescent tube 2 and filled with the discharge gas. Parallel portions 7a, 8a are arranged on the discharge space insulating electrodes 3, 4 of the seven fluorescent lamp tubes 2, and wirings 7, 8 for app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com