Acidic dye dyeing method of cotton textiles

A dyeing method and technology of cotton textiles, applied in the field of textile printing and dyeing, can solve the problems of poor wear resistance and high dye content, achieve the effects of increasing dye uptake, improving light fastness, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

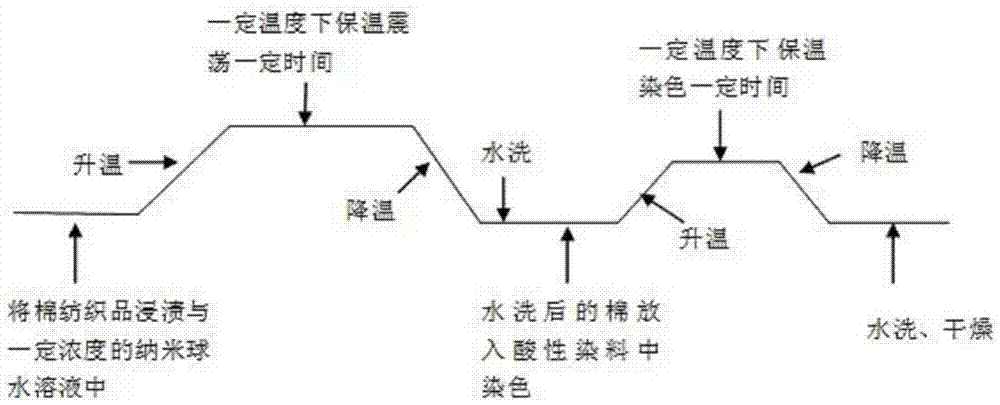

Method used

Image

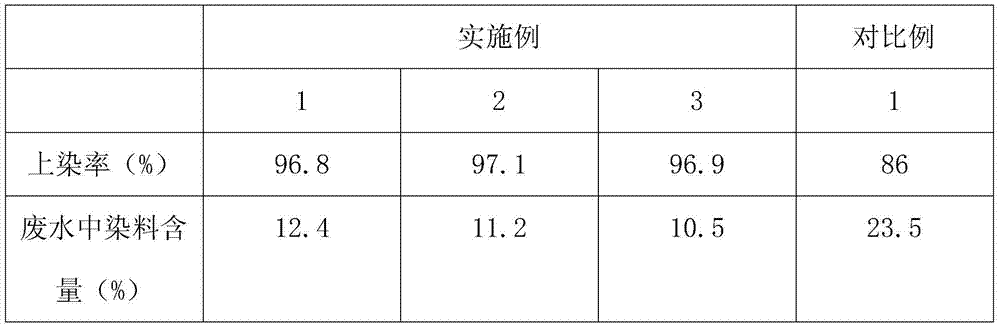

Examples

Embodiment 1

[0023] (1) Preparation of carboxylated carbon nanospheres:

[0024] After mixing the carbon nanospheres with the mixed solution of sulfuric acid and hydrochloric acid according to the mass ratio of 0.025:1, the suspension was prepared by ultrasonic treatment for 10-20 minutes, and the suspension was soaked for 25 hours, then heated at 110°C to reflux for 1.5 hours, and finally washed and washed repeatedly. Separate until the pH is neutral to remove impurities in the carbon nanospheres and bring active reactive groups such as carboxyl groups on the surface to obtain carboxylated carbon nanospheres.

[0025] (2) Prepare the modified carboxylated carbon nanospheres into a 0.02% water dispersion, then add the carboxylated carbon nanosphere solution into the dyeing bath and rotate for 20 minutes, and finally press the quality of the carboxylated carbon nanospheres and acid dye Add acid dye with a ratio of 0.07:1, and fix the color with formic acid after dyeing is finished.

Embodiment 2

[0027] (1) Preparation of carboxylated carbon nanospheres:

[0028] After mixing the carbon nanospheres with the mixed solution of sulfuric acid and hydrochloric acid according to the mass ratio of 0.02:1, the suspension is prepared by ultrasonic treatment for 10 to 20 minutes, soaked for 24 hours, then heated and refluxed at 100°C for 1 hour, and finally washed and separated repeatedly Until the pH is neutral, the impurities in the carbon nanospheres are removed, and the surface of the carbon nanospheres is equipped with active reactive groups such as carboxyl groups to obtain carboxylated carbon nanospheres.

[0029] (2) Prepare the modified carboxylated carbon nanospheres into a 0.01% aqueous dispersion, then add the carboxylated carbon nanosphere solution to the dye bath and rotate for 10 minutes, and finally press the mass of the carboxylated carbon nanospheres and the acid dye Add acid dye at a ratio of 0.005:1, and fix the color with formic acid after dyeing is finished.

Embodiment 3

[0031] (1) Preparation of carboxylated carbon nanospheres:

[0032] After mixing the carbon nanospheres with the mixed solution of sulfuric acid and hydrochloric acid according to the mass ratio of 0.03:1, the suspension is prepared by ultrasonic treatment for 10-20 minutes, soaked for 30h, then heated at 120℃ to reflux for 2h, and finally washed and separated repeatedly Until the pH is neutral, the impurities in the carbon nanospheres are removed, and the surface of the carbon nanospheres is equipped with active reactive groups such as carboxyl groups to obtain carboxylated carbon nanospheres.

[0033] (2) Prepare the modified carboxylated carbon nanospheres into a 0.03% water dispersion, then add the carboxylated carbon nanosphere solution to the dye bath and rotate for 30 minutes, and finally press the mass of the carboxylated carbon nanospheres and the acid dye Add acid dye at a ratio of 0.01:1, and fix the color with formic acid after dyeing is finished.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com