Preparation method of dancing rainbow yarn fiber Raschel blanket

A Raschel blanket and fiber technology, applied in the direction of dyeing, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of monotonous patterns and poor dyeing performance of Raschel blankets, and achieve fine hand feeling and high color fastness. , the effect of reducing the content of difficult-to-biodegrade dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

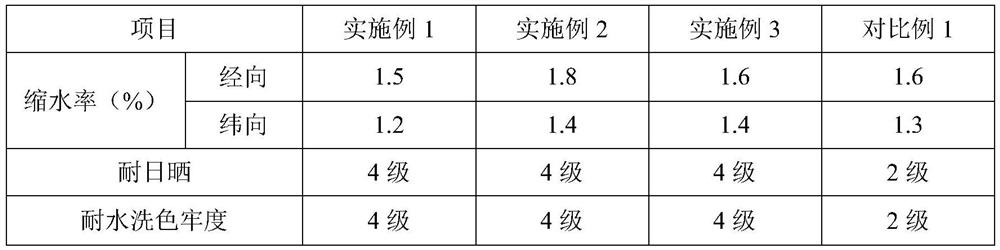

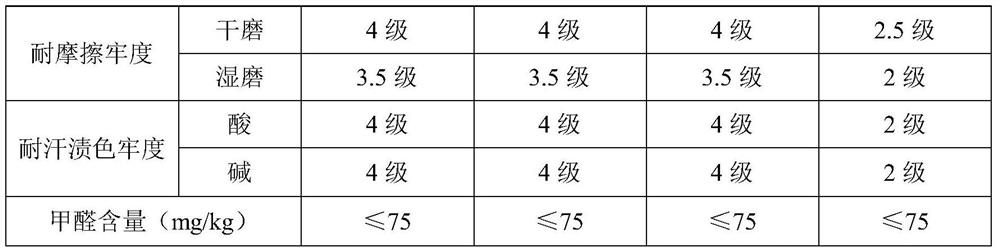

Examples

Embodiment 1

[0044] A preparation method for a Wuhong yarn fiber Raschel blanket, comprising the steps of:

[0045] (1) Weaving: DTY200D / 288f Wuhong yarn fiber (twisted direction is S+Z twist) is used as plush yarn, 75D / 36f polyester full-drawn yarn is used as base yarn, and GE2888 high-speed double-needle bed warp knitting machine is used. The rotating speed is 590 rpm, the warp let-off method adopts electronic warp let-off, and the gauge is 18mm, and the method of lapping yarns in the same direction is used to weave on a high-speed warp knitting machine to obtain gray cloth;

[0046] (2) Pre-finishing: Pre-finish gray fabrics after presetting along the wool, pre-scalding against the wool, high combing along the wool, and alternate ironing against the wool to obtain the gray fabric after pre-finishing; the presetting temperature for the wool is 125°C, The speed is 32m / min, the speed of the upper fan is 30Hz, and the speed of the lower fan is controlled at 40Hz; the pre-scalding temperatur...

Embodiment 2

[0057] A preparation method for a Wuhong yarn fiber Raschel blanket, comprising the steps of:

[0058] (1) Weaving: DTY200D / 288f Wuhong yarn fiber (twisted direction is S+Z twist) is used as plush yarn, 75D / 36f polyester full-drawn yarn is used as base yarn, and GE2888 high-speed double-needle bed warp knitting machine is used. The rotating speed is 580 rpm, the warp let-off method adopts electronic warp let-off, and the gauge is 17mm, and the method of lapping yarns in the same direction is used to weave on a high-speed warp knitting machine to obtain gray cloth;

[0059] (2) Pre-finishing: Pre-finish gray fabrics after presetting along the wool, pre-scalding against the wool, high combing along the wool, and alternate ironing against the wool to obtain the gray fabric after pre-finishing; The speed is 31m / min, the upper fan speed is 35Hz, the lower fan speed is controlled at 45Hz; Reverse ironing and four sequential ironing methods, ironing temperature 195°C, speed 16m / min,...

Embodiment 3

[0070] A preparation method for a Wuhong yarn fiber Raschel blanket, comprising the steps of:

[0071] (1) Weaving: DTY200D / 288f Wuhong yarn fiber (twisted direction is S+Z twist) is used as plush yarn, 75D / 36f polyester full-drawn yarn is used as base yarn, and GE2888 high-speed double-needle bed warp knitting machine is used. The rotating speed is 600 rpm, the warp let-off method adopts electronic warp let-off, and the gauge is 19mm, and the method of lapping yarns in the same direction is used to weave on a high-speed warp knitting machine to obtain gray cloth;

[0072] (2) Pre-finishing: Pre-finish gray fabrics after presetting along the wool, pre-scalding against the wool, high combing along the wool, and alternate ironing against the wool to obtain the gray fabric after pre-finishing; The speed is 33m / min, the speed of the upper fan is 30Hz, and the speed of the lower fan is controlled at 40Hz; the pre-scalding temperature of reverse wool is 205°C, and the speed is 18m / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com