Preparation method for polymeric dye based on hyperbranched polyamine-ester

A polymer dye and hyperbranched polymerization technology, applied in the field of polymer dye preparation, can solve problems that have not yet been discovered, and achieve the effect of improving the utilization rate of dye and reducing the content of dye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

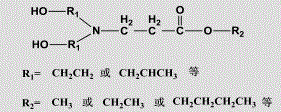

[0024] Weigh 13.32g of diisopropanolamine and 30g of methanol into a four-necked flask, slowly raise the temperature to 40°C, then slowly drop 8.6g of methyl acrylate into the four-necked flask for about 12 hours, and remove the methanol under reduced pressure to obtain AB 2 type monomer.

[0025] Add 21.92gAB to the four-neck bottle 2 Type monomer, 0.64g trimethylolpropane, 0.22g p-toluenesulfonic acid were incubated and reacted at 120°C for 4 hours, and then vacuumized to continue the reaction for 4 hours to obtain the third-generation hyperbranched polyamine-ester. Cool the reactant to 90°C, add 8.96g of maleic anhydride, react for 4h, then cool down to below 60°C, and neutralize to pH 8-9 with 30% sodium hydroxide solution.

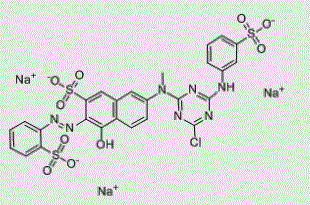

[0026] Dissolve 6.18g of reactive yellow K-RN in 37g of water, add the above product, and react at 60°C for 2h to obtain a yellow water-soluble polymer dye based on hyperbranched polyamine-ester.

Embodiment 2

[0028] Weigh 10.5g of diethanolamine and 30g of ethanol into the four-necked flask, slowly raise the temperature to 35°C, then slowly drop 8.6g of methyl acrylate into the four-necked flask, react for about 6 hours, and remove the ethanol under reduced pressure to obtain AB 2 type monomer.

[0029] Add 19.1gAB in the four-necked bottle 2 Type monomer, 0.44g glycerol, 0.20g p-toluenesulfonic acid, react at 100°C for 4h, and then continue to react for 4h under vacuum. The temperature of the reactant was lowered to 80°C, 2.28g of succinic anhydride was added, reacted for 4h, then cooled to below 40°C, and neutralized to pH 8-9 with 30% sodium hydroxide solution.

[0030] Dissolve 4.84g of Reactive Brilliant Orange K-GN in 29g of water, add the above product, and react at 95°C for 2h to obtain an orange water-soluble polymer dye based on hyperbranched polyamine-ester.

Embodiment 3

[0032] Weigh 10.5g of diethanolamine and 30g of ethanol into a four-necked flask, slowly raise the temperature to 40°C, then slowly drop 10g of ethyl acrylate into the four-necked flask, react for about 24 hours, and remove ethanol under reduced pressure to obtain AB 2 type monomer.

[0033] Add 20.5gAB to the four-necked bottle 2 Type monomer, 0.71g triethanolamine, 0.21g p-toluenesulfonic acid were reacted under vacuum at 140°C for 8h to obtain the third generation hyperbranched polyamine-ester. The temperature of the reactant was lowered to 80°C, 5.7g of succinic anhydride was added, reacted for 4h, then cooled to below 40°C, and neutralized to pH 8-9 with 30% sodium hydroxide solution.

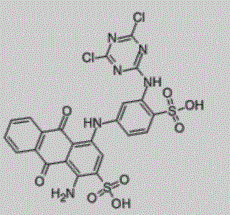

[0034] After dissolving 9g of Reactive Brilliant Blue X-ARL in 39g of water, add the above product and react at 70°C for 2h to obtain a blue water-soluble polymer dye based on hyperbranched polyamine-ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com