Cold pad batch processing method of cotton fibers through pre-treatment dyeing one-bath method

A technology of pre-treatment dyeing and processing method, which is applied in the technical field of pre-treatment dyeing and treatment of cotton and loose fibers in the same bath, can solve the problems of low production efficiency, high water and energy consumption, affecting spinning, etc. The effect of less energy consumption and water saving and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

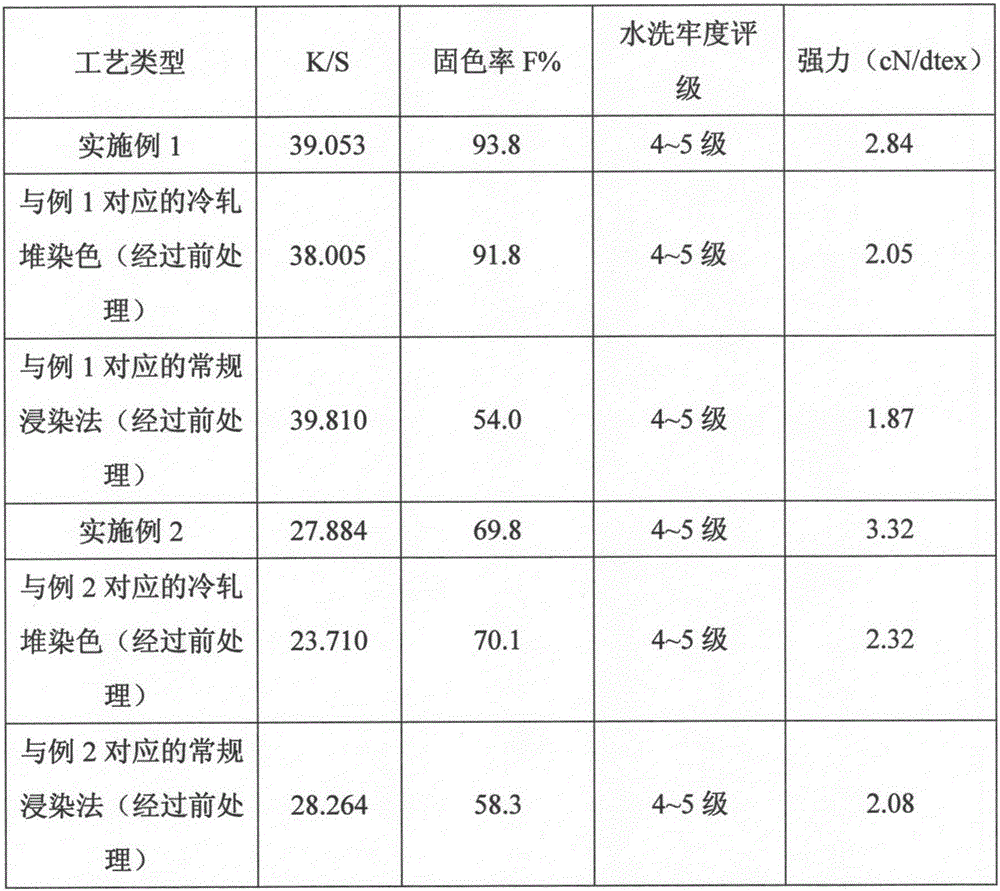

Examples

Embodiment 1

[0027] A cold pad-batch processing method for cotton fibers by pretreatment dyeing in the same bath method, the specific steps are:

[0028] Weigh 2g of raw cotton loose fiber after carding, and pad it in the dipping solution, and impregnate it twice for 10 minutes. Put it in place for 12 hours, first wash with hot water at 70-80°C, soap wash (commercial grade soaping agent 2g / L, bath ratio 1:20, temperature 95°C, time 10min), then wash with cold water, dry at 80-95°C to obtain dyed Cotton fiber.

[0029] The formula of described dipping solution is: reactive black KN-B (two active radicals) 40g / L, urea 50g / L, sodium sulfate 30g / L, refining penetrating agent JFC 4g / L, alkaline pectinase 2g / L L, caustic soda 3g / L, sodium silicate 15g / L. When preparing, add water successively to mix at room temperature, and stir evenly.

Embodiment 2

[0031] A cold pad-batch processing method for cotton fibers by pretreatment dyeing in the same bath method, the specific steps are:

[0032] Weigh 2g of raw cotton loose fiber after carding, and pad it in the dipping solution, and impregnate it twice for 10 minutes. Put it in place for 12 hours, first wash with hot water at 70-80°C, soap wash (commercial grade soaping agent 2g / L, bath ratio 1:20, temperature 95°C, time 10min), then wash with cold water, dry at 80-95°C to obtain dyed Cotton fiber.

[0033] The formula of the impregnation solution is: reactive brilliant blue KN-R 20g / L, urea 50g / L, sodium sulfate 30g / L, refining penetrant JFC 4g / L, alkaline pectinase 2g / L, soda ash 2g / L, Sodium silicate 10g / L. When preparing, add water successively to mix at room temperature, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com