Salt-free cold pad batch dyeing method for uncooked and unbleached cotton fibers

A cold pad-batch dyeing and cotton fiber technology, which is applied in the field of cotton fiber printing and dyeing, can solve the problems of shortening the dyeing time of reactive dyes, excessive water consumption and salt consumption, and no cotton-type fabric dyeing, so as to solve the problem of unsatisfactory color fixation rate , high color fixation rate, and increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

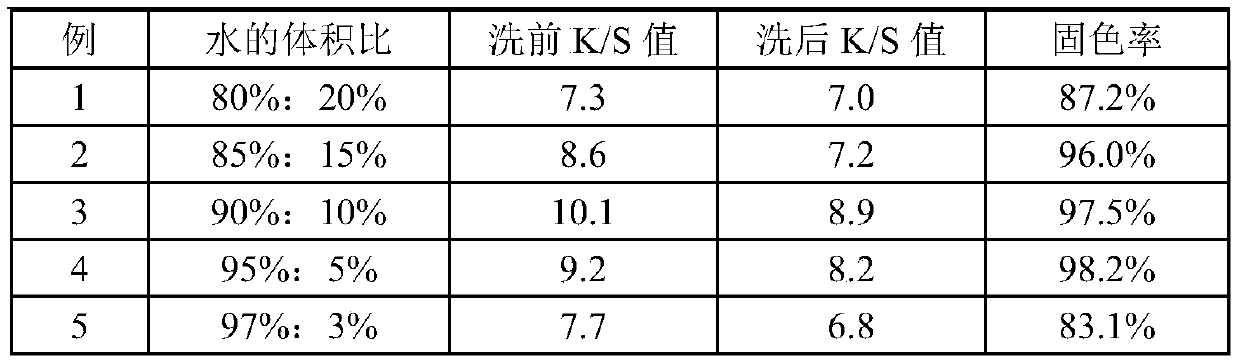

Embodiment 1

[0032] S1. Preparation of dye liquor: Place Reactive Red 195 and sodium carbonate in a mixture of ethanol and water, stir evenly and prepare dye liquor. The volume ratio of ethanol and water in the dye liquor is 80%:20%. The concentration of reactive dyes is 5g / L, and the concentration of sodium carbonate is 25g / L;

[0033] S2. Pad dyeing liquor: Place the uncooked and bleached cotton yarn in the prepared dyeing liquor, padding for 30s at a temperature of 25°C, two soaking and two padding liquor, bath ratio of 1:20 to make pad dyeing The residual rate of uncooked and bleached cotton yarn after liquid is 70%;

[0034] S3. Rolling and stacking: the uncooked and bleached cotton yarn dyed in step S2 is wound on a winder, and the rolled uncooked and bleached cotton yarn is wrapped in a plastic film and then stacked, where the stacking temperature is 35°C, The stacking time is 8h, and the rotation speed is 5r / min;

[0035] S4. Washing: the uncooked and bleached cotton yarn processed in s...

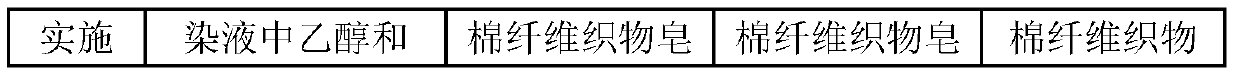

Embodiment 6-10

[0042] On the basis of Example 1, the volume ratio of ethanol and water in the dye liquor is 85%:15%, the concentration of the reactive dye in the dye liquor is 15g / L, the alkaline substance is sodium carbonate, and the concentration of sodium carbonate is 20 ~40g / L, the padding solution is dipped for 17s at a temperature of 27℃, and the bath ratio is 1:25. The sliver of uncooked and bleached sliver after the padding solution is 90%, coiled and stacked The conditions are that the stacking temperature is 30°C, the stacking time is 16h, and the rotation speed is 7r / min.

[0043] Taking into account the influence of the concentration of alkaline substances in the dye liquor on the fixation rate, under other conditions unchanged, by changing the concentration of the alkaline substances, the change law of the fixation rate of uncooked slivers was investigated, Example 6 10, as shown in Table 2.

[0044] Table 2:

[0045]

[0046]

[0047] It can be seen from Table 2 that as the concentr...

Embodiment 11-15

[0049] On the basis of Example 1, the volume ratio of ethanol and water in the dye liquor is 95%:5%, the concentration of reactive dye in the dye liquor is 25g / L, and the alkaline substance is sodium bicarbonate and sodium bicarbonate. It is 30g / L, the padding solution is dipped for 25s at a temperature of 20-35℃, and the bath ratio is 1:30. The sliver of uncooked and bleached sliver after the padding solution is 100%. The stacking conditions are that the stacking temperature is 30°C, the stacking time is 8h, and the rotation speed is 10r / min.

[0050] Considering the influence of the temperature of the padding dyeing solution on the fixation rate, under other conditions unchanged, by changing the padding temperature, the change rule of the fixation rate of the uncooked sliver was investigated. Examples 11-15, such as Table 3 shows.

[0051] table 3:

[0052]

[0053] It can be seen from Table 3 that as the padding temperature increases, the fixation rate of the uncooked bleached s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com