A kind of preparation method of Raschel blanket of Fidelon absorbing and discharging silk fiber

A raschel blanket and silk fiber technology is applied in the field of preparation of Fidelity fiber raschel blankets, which can solve the problem of inability to meet the diverse needs of consumers, poor comfort in use, and poor moisture absorption and perspiration performance. problem, to achieve good moisture absorption and quick-drying performance, improve dye uptake and fixation rate, and prevent contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

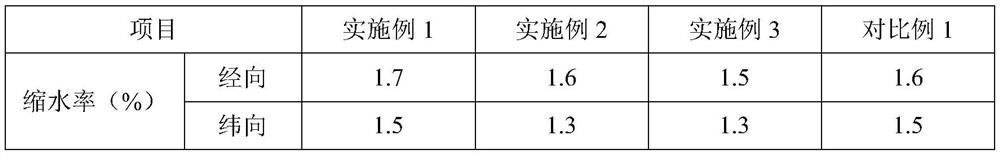

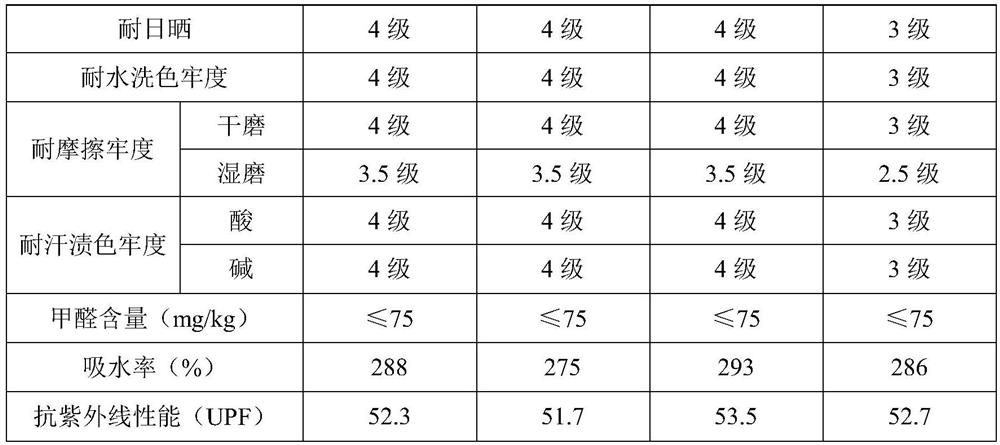

Examples

Embodiment 1

[0044] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0045] (1) Weaving: use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as bottom yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 590 rpm, let-off The method adopts electronic warp let-off, and the gauge is 18mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft inlay in the same direction to obtain gray cloth;

[0046] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 203℃, and the speed is 17m / min; / min, the ironing roller uses W groove; the predetermined temperature...

Embodiment 2

[0057] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0058] (1) Weaving: Use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as base yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 580 rpm, let-off The method adopts electronic warp let-off with a gauge of 17mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft padding in the same direction to obtain gray cloth;

[0059] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 200℃, and the speed is 16m / min; / min, the ironing roller uses the W groove; the predetermined temperatu...

Embodiment 3

[0070] A method for preparing a Raschel blanket of Fidelon suction and discharge silk fiber, comprising the following steps:

[0071] (1) Weaving: use DTY300D / 96f Fidelity fiber as plush yarn, 150D / 36f polyester full-drawn yarn as base yarn, use GE2888 high-speed double-needle bed warp knitting machine, the speed is 600 rpm, let-off The method adopts electronic warp let-off, and the gauge is 19mm, and weaves on a high-speed warp knitting machine by adopting the method of full-threading three-needle and four-needle weft inlay in the same direction to obtain gray cloth;

[0072] (2) Pre-finishing: the gray cloth is scalded first and then pre-set to obtain the gray cloth after pre-finishing; when ironing, it is firstly pre-scalded against the wool, then combed along the wool, and finally alternately ironed against the wool Light; the pre-scalding temperature of reverse wool is 205℃, and the speed is 18m / min; the high combing speed of smooth wool is 18m / min; / min, the ironing rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com