Reactive dye dyeing method for cotton fabric

A technology of reactive dyes and dyeing methods, which is applied in the field of reactive dye liquid paraffin bath dyeing, can solve the problems of low utilization rate of dyestuffs, difficult treatment, and high salt content, and achieves significant waste water discharge, increased utilization rate, and high dyeing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: (active black KN-B)

[0031] 1. Dyeing formula and conditions:

[0032] Reactive dye (reactive black KN-B): 4% (o.w.f);

[0033] Sodium carbonate concentration: 40g / L;

[0034] Cotton fabric weight: 1g;

[0035] Squeezing rate: 150%;

[0036] The mass ratio of cotton fabric to liquid paraffin: 1:40;

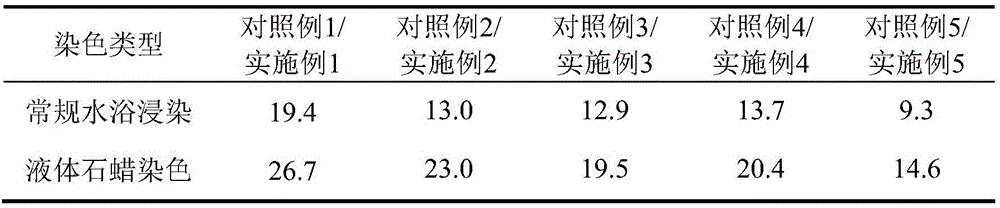

[0037] Table 1 Embodiment 1 used liquid paraffin related parameters

[0038]

[0039] 2. Dyeing process:

[0040] (1) Pretreatment of cotton fiber: Weigh 1 g of cotton fabric and put it into a sodium carbonate solution with a concentration of 40 g / L, with a bath ratio of 1:50. After soaking for 30 minutes at normal temperature, squeeze out the liquid, control the cotton fabric's liquid squeeze rate to 150%, and prepare for dyeing.

[0041] (2) Dyeing: According to the ratio, reactive dyes and liquid paraffin are mixed to form a reactive dye / liquid paraffin suspension dispersion, and the cotton fabric obtained in step (1) is put into the reactive dye...

Embodiment 2

[0044] Embodiment 2: (active black KN-B)

[0045] 1. Dyeing formula:

[0046] Reactive dye (reactive black KN-B): 2% (o.w.f);

[0047] Sodium carbonate concentration: 40g / L;

[0048] Cotton fabric weight: 1g;

[0049] The mass ratio of cotton fabric to liquid paraffin: 1:20;

[0050] Squeezing rate: 200%;

[0051] Liquid paraffin kind is with embodiment 1

[0052] 2, dyeing process: adopt above-mentioned dyeing formula, concrete dyeing process is the same as embodiment 1, difference is: in step (2), dyestuff is used m 活性染料 :m 水 = Dissolve in water at 1:5, then add liquid paraffin, shake and shake well, then put the cotton fabric obtained in step (1) into the dyeing solution at room temperature, and dye for 20 minutes; in step (3), the mixture system is heated to 70°C, keep warm for 50min.

Embodiment 3

[0053] Embodiment 3: (active black KN-B)

[0054] 1. Dyeing formula:

[0055] Reactive dye (reactive black KN-B): 2% (o.w.f);

[0056] Sodium carbonate concentration: 10g / L;

[0057] Cotton fabric weight: 1g;

[0058] Squeezing rate: 100%;

[0059] The mass ratio of cotton fabric to liquid paraffin: 1:60;

[0060] Liquid paraffin kind is with embodiment 1

[0061] 2, dyeing process flow: adopt above-mentioned dyeing formula, concrete dyeing process flow is the same as embodiment 2, difference is: in step (2), dyestuff is used m 活性染料 :m 水 =1:10 dissolved in water, then add liquid paraffin, shake well, then put the cotton fabric obtained in step (1) into the dye solution at room temperature, and dye for 40 minutes; in step (3), the mixture system is heated to 50°C, keep warm for 50min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com