Process for producing modified PET/PTT elastic fiber

A technology of elastic fiber and production process, which is applied in the field of production process of modified elastic fiber, can solve the problems of inconspicuous effect, high cost, affecting dyeing rate, etc., and achieve advanced and reasonable production process, lower production cost and high dyeing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

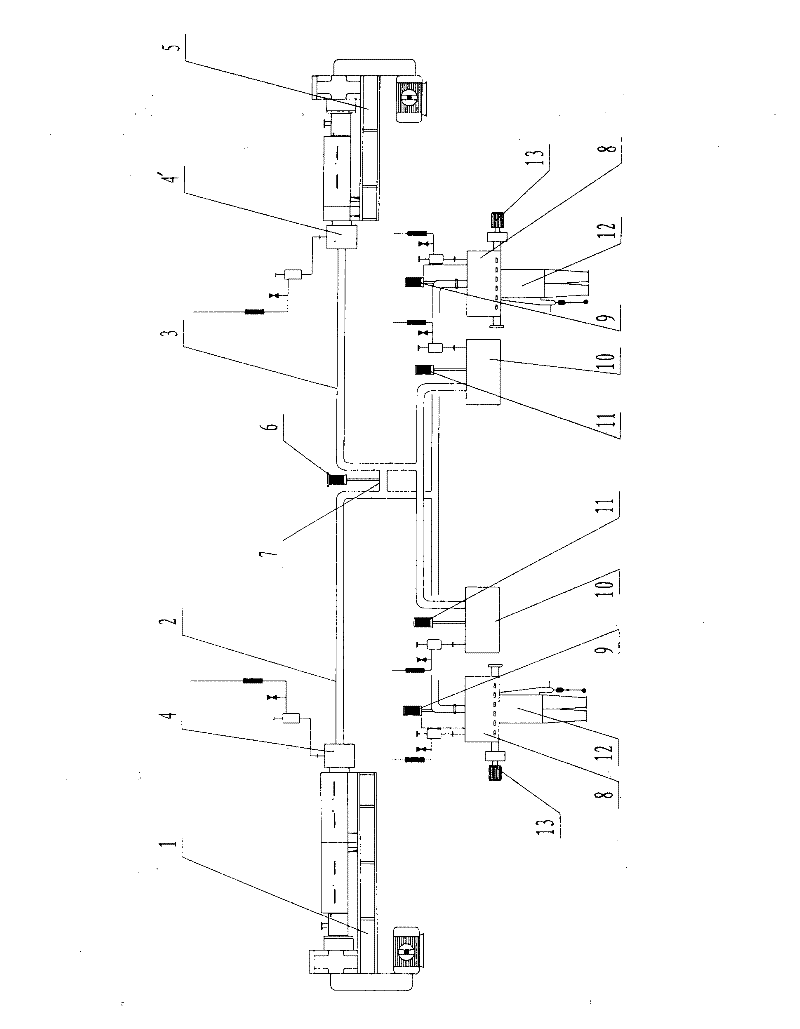

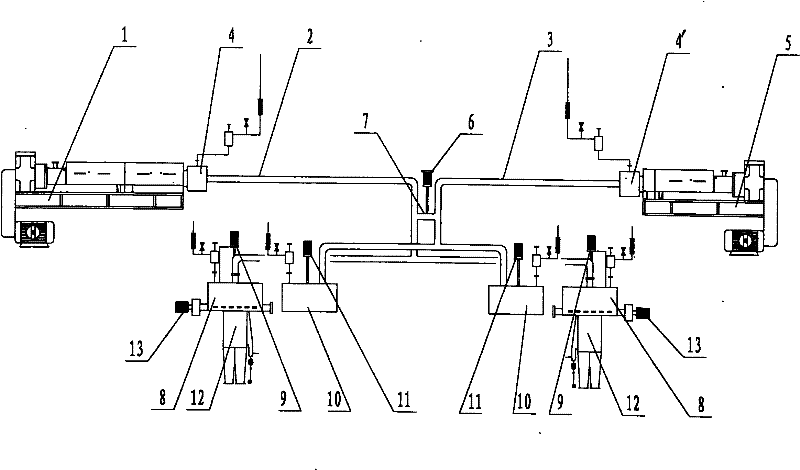

[0015] Referring to the accompanying drawings, the composite spinning equipment, process route and technical conditions are used for production, and the fiber forms a peanut-shaped structure.

[0016] The composite spinning equipment mainly includes a composite spinning box, which includes a main box, an auxiliary box, a metering pump, a spinning assembly, a screw extruder, a melt pipeline, a winding machine, a drafting machine, etc.

[0017] Raw materials are processed in the early stage: first, the PTT and PET slices are thickened.

[0018] The material distribution ratio of each layer of PET / PTT elastic fiber: the outer layer uses PTT, accounting for about 30% of the total material weight, the inner layer uses PET accounting for 60% of the total material weight and PTT accounting for 10% of the total material weight, the total ratio: PET:PTT is 60:40.

[0019] After processing and drying, the PET chips are extruded and melted into the PET screw extruder 1 to become a spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com