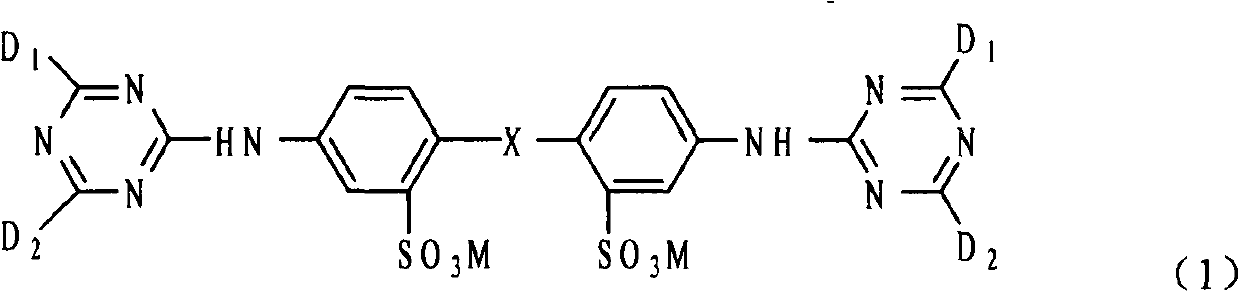

Triazine type azo dye and preparation method thereof

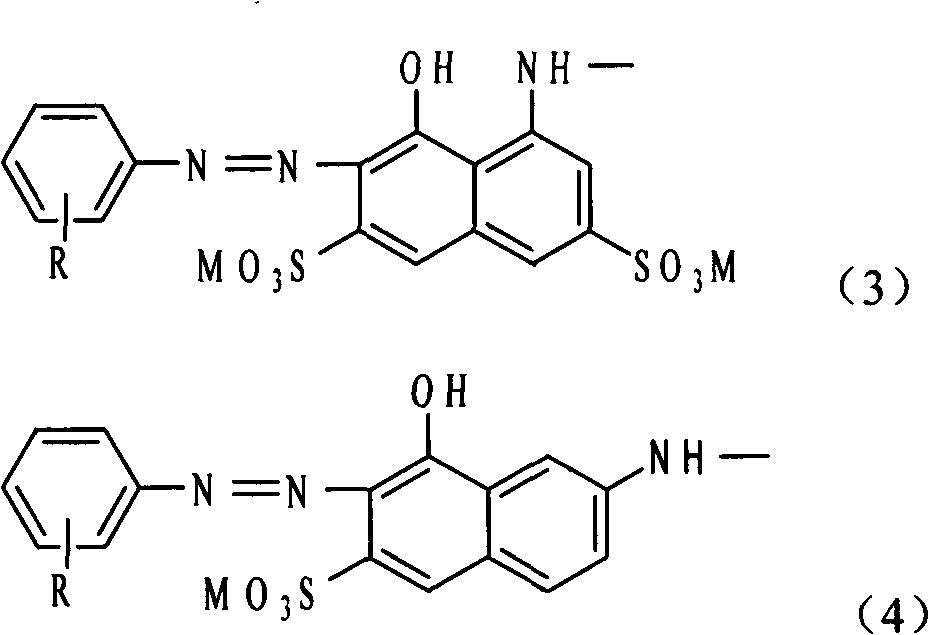

A kind of technology of azo dyes and triazine type, applied in the field of triazine type azo dyes and its preparation, can solve the problems of heat resistance, poor color fastness to light, easy decomposition, affecting the dyeing performance of azo dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] a) Add 40g of water, 0.8g of wetting agent and 60g of ice into a 500mL reaction flask, control the temperature at 0-1°C with an ice-salt bath, and stir rapidly; then add 18.6g of cyanuric chloride (99%, MW=184.5 , 0.10mol), stirred rapidly for 30 minutes, ground cyanuric chloride in ice-water mixture, and controlled the temperature at 0-1°C. The product is a white suspension.

[0065] b) Add 27.5g of water and 1.8g of NaHCO to a 100mL beaker 3 And 16.3gDSD acid (96.68%, MW=370.41, 0.0425mol), stir well; Then add NaHCO carefully 3 Adjust the pH to 6.5-6.8, stir until the DSD acid is completely dissolved, add a small amount of antifoaming agent to defoam; add 20g of ice to it and cool down to 0-5°C, pH = 6.5-7.0.

[0066] c) Add the DSD acid solution in the above second step b) dropwise to the cyanuric chloride solution to carry out the first condensation reaction, the dropping time is controlled at about 1h, and the reaction temperature is controlled at 0-3 with an ice...

Embodiment 2

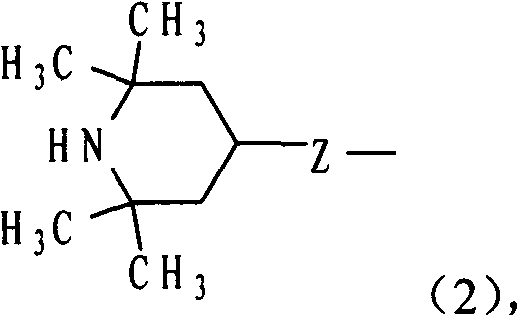

[0078] As in Example 1, 18.6g of cyanuric chloride was weighed and condensed with 16.3g of DSD acid, 29.0g of H acid monosodium salt and 13.3g of 4-amino-2,2,6,6-tetramethylpiperidine (TEMP) successively, The tricondensate was coupled with 7.9 g of aniline diazonium salt to obtain the triazine-type azo dye of the general formula (1) of the present invention.

Embodiment 3

[0080] As in Example 1, 18.6g of cyanuric chloride was weighed and condensed with 13.3g of 4-amino-2,2,6,6-tetramethylpiperidine (TEMP), 29.0g of monosodium H acid and 16.3g of DSD successively. The tricondensate was coupled with 7.9 g of aniline diazonium salt to obtain the triazine-type azo dye of the general formula (1) of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com