Environmental protection micro injection color paste

An environmentally friendly and color paste technology, applied in the field of environmentally friendly plastic drop plastic color paste, can solve problems such as carcinogenicity, ecological environment and human health threats, and achieve the effects of less harmful pollution, less green environmental protection, and uniform coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

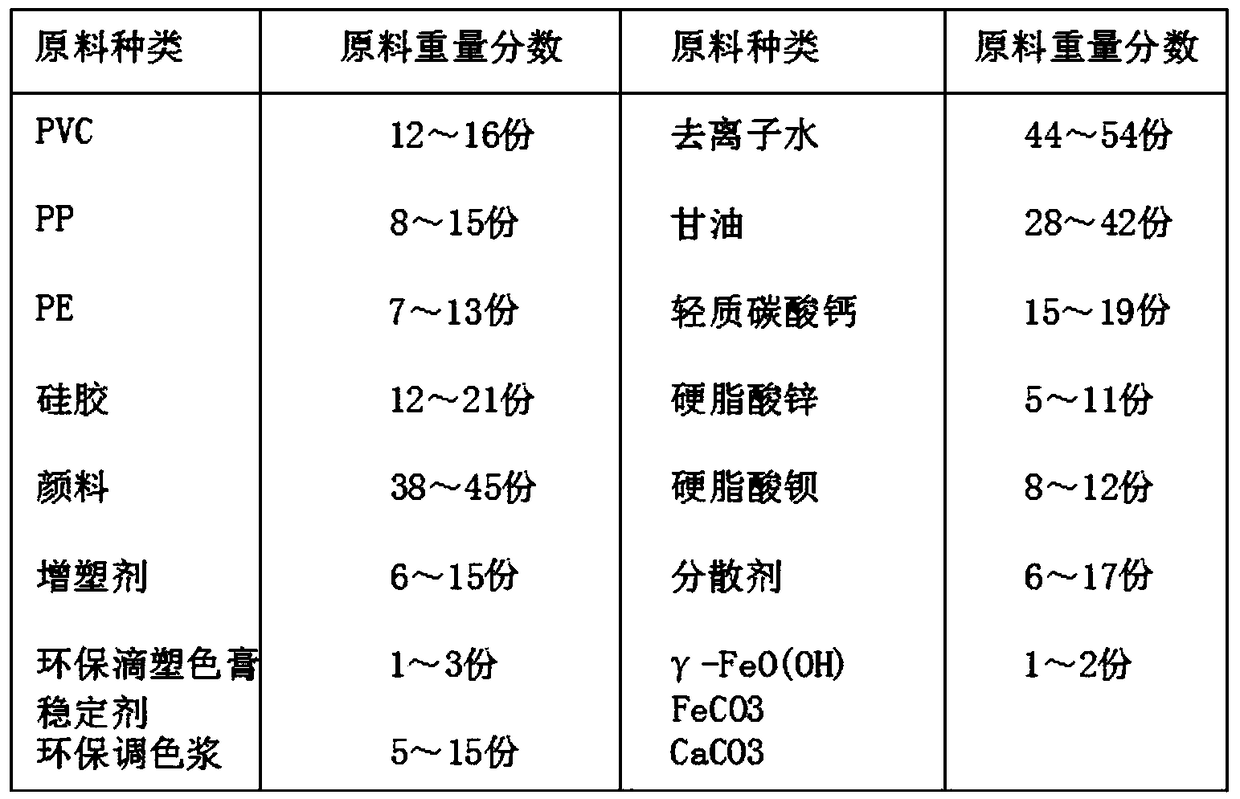

[0018] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly plastic drop color paste, which includes the following raw materials: 16 parts of PVC, 15 parts of PP, 13 parts of PE, 21 parts of silica gel, and 45 parts of pigments , 15 parts of plasticizer, 54 parts of deionized water, 42 parts of glycerin, 19 parts of light calcium carbonate, 11 parts of zinc stearate, 12 parts of barium stearate and 17 parts of dispersant.

[0019] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 3 parts of environment-friendly drop plastic color paste stabilizer.

[0020] Wherein, the environment-friendly drop plastic color paste stabilizer includes 60% organic zinc stabilizer and 40% phosphite stabilizer.

[0021] Wherein, the plasticizer is epoxy ethyl phthalate.

[0022] Wherein, the dispersant is sodium dodecylsulfonate.

[0023] Wherein, 2 parts of γ-FeO(OH), FeCO 3 and CaTiO 3 A mixture of w...

Embodiment 2

[0027] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly plastic drop color paste, which includes the following raw materials: 12 parts of PVC, 8 parts of PP, 7 parts of PE, 12 parts of silica gel, and 38 parts of pigments , 6 parts of plasticizer, 44 parts of deionized water, 28 parts of glycerin, 15 parts of light calcium carbonate, 5 parts of zinc stearate, 8 parts of barium stearate and 6 parts of dispersant.

[0028] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 1 part of environment-friendly drop plastic color paste stabilizer.

[0029] Wherein, the environmentally friendly drop plastic color paste stabilizer includes 45% organic zinc stabilizer and 55% phosphite stabilizer.

[0030] Wherein, the plasticizer is epoxy ethyl phthalate, epoxy butyl phthalate and epoxy dioctyl phthalate, wherein, epoxy ethyl phthalate, epoxy phthalate The ratio of butyl phthalate to dioctyl e...

Embodiment 3

[0036] see figure 1 As shown, the technical solution adopted in the present invention is: an environmentally friendly plastic drop color paste, which includes the following raw materials: 16 parts of PVC, 8 parts of PP, 13 parts of PE, 12 parts of silica gel, and 45 parts of pigments , 6 parts of plasticizer, 54 parts of deionized water, 28 parts of glycerin, 19 parts of light calcium carbonate, 5 parts of zinc stearate, 12 parts of barium stearate and 6 parts of dispersant.

[0037] Wherein, the polyvinyl chloride environment-friendly color paste is also added with 3 parts of environment-friendly drop plastic color paste stabilizer.

[0038] Wherein, the environmentally friendly drop plastic color paste stabilizer includes 45% organic zinc stabilizer and 55% phosphite stabilizer.

[0039] Wherein, the plasticizer is epoxy butyl phthalate.

[0040] Wherein, the dispersant is sodium lauryl sulfate.

[0041] Wherein, 1 part of γ-FeO(OH), FeCO 3 and CaTiO 3 A mixture of whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com