Dual agent type clear water physical hair dyeing foam

A two-part, clear water technology, applied in hair care, cosmetics, cosmetic preparations, etc., can solve the problems of insufficient chromaticity of foam and insufficient fineness of foam, and achieve the effects of good experience, rich foam, and good chromaticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

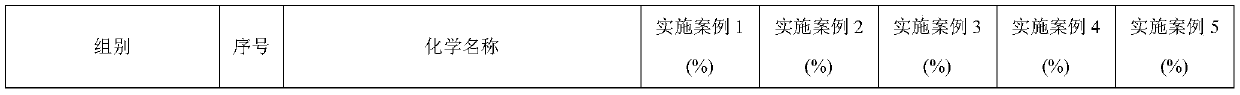

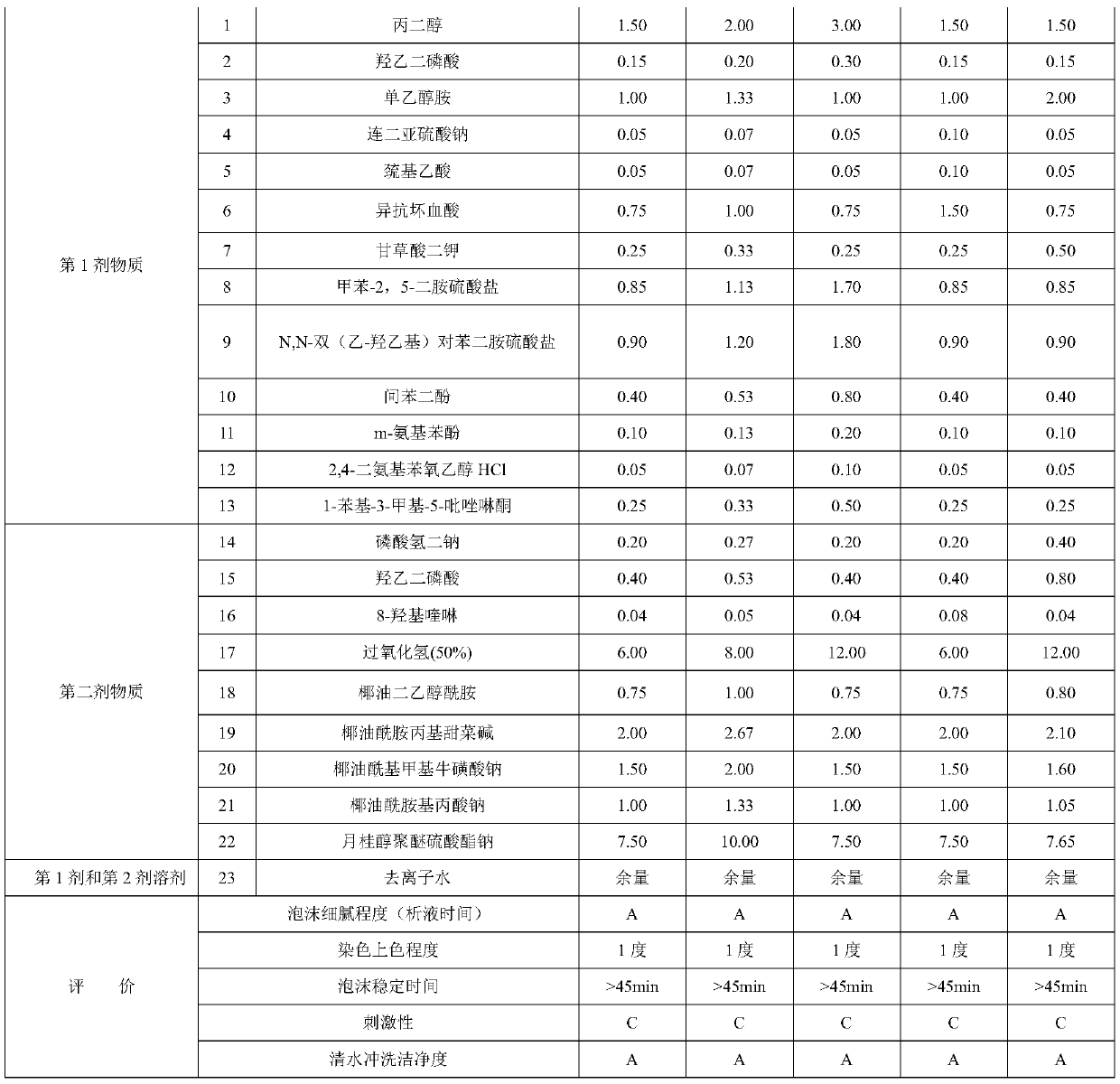

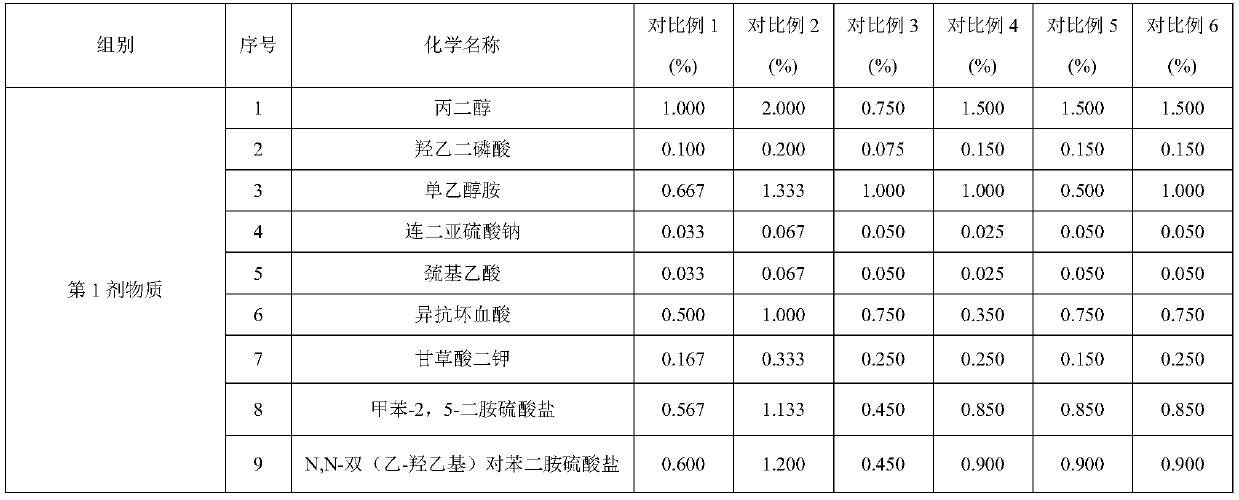

[0031] The effects of the present invention will be further illustrated below through specific examples.

[0032] Test methods and evaluation criteria for each performance index:

[0033] (1) Foam fineness standard: After mixing the first dose and the second dose, make a foam, apply it evenly on the hair, and observe the time when the foam disappears.

[0034] (2) Foam fineness standard: foam particle size < 0.5mm, grade A; foam particle size ≥ 0.5mm, grade B; foam particle size ≥ 1mm, grade C.

[0035] (3) Skin irritation detection standard: After mixing ingredients A and B, make a foam, apply it on the skin, and observe the irritation of the skin: within 5 minutes after applying the hair dye foam, the skin feels itchy, dry and other discomfort, judge The irritation is grade A; when the hair dye foam is applied and the skin feels itchy and dry within 30 minutes and less than or equal to 60 minutes, the irritation is judged as grade B; when the hair dye foam is applied and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com