Trimming and coloring device of paper box piece die

A side coloring, carton box technology, applied in the direction of packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low work efficiency, large amount of ink consumption, high labor intensity, etc., and achieve simple structure, uniform coloring, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The carton box sheet die-cut edge coloring device of the present invention, its preferred embodiment is:

[0016] It includes a machine base on which a stacking device, an inkjet device and a lifting device are arranged. The inkjet device includes a nozzle, the nozzle is installed on the lifting device, and boxes are stacked on the stacking device. The nozzle is aimed at the die-cutting edge of the box to be colored.

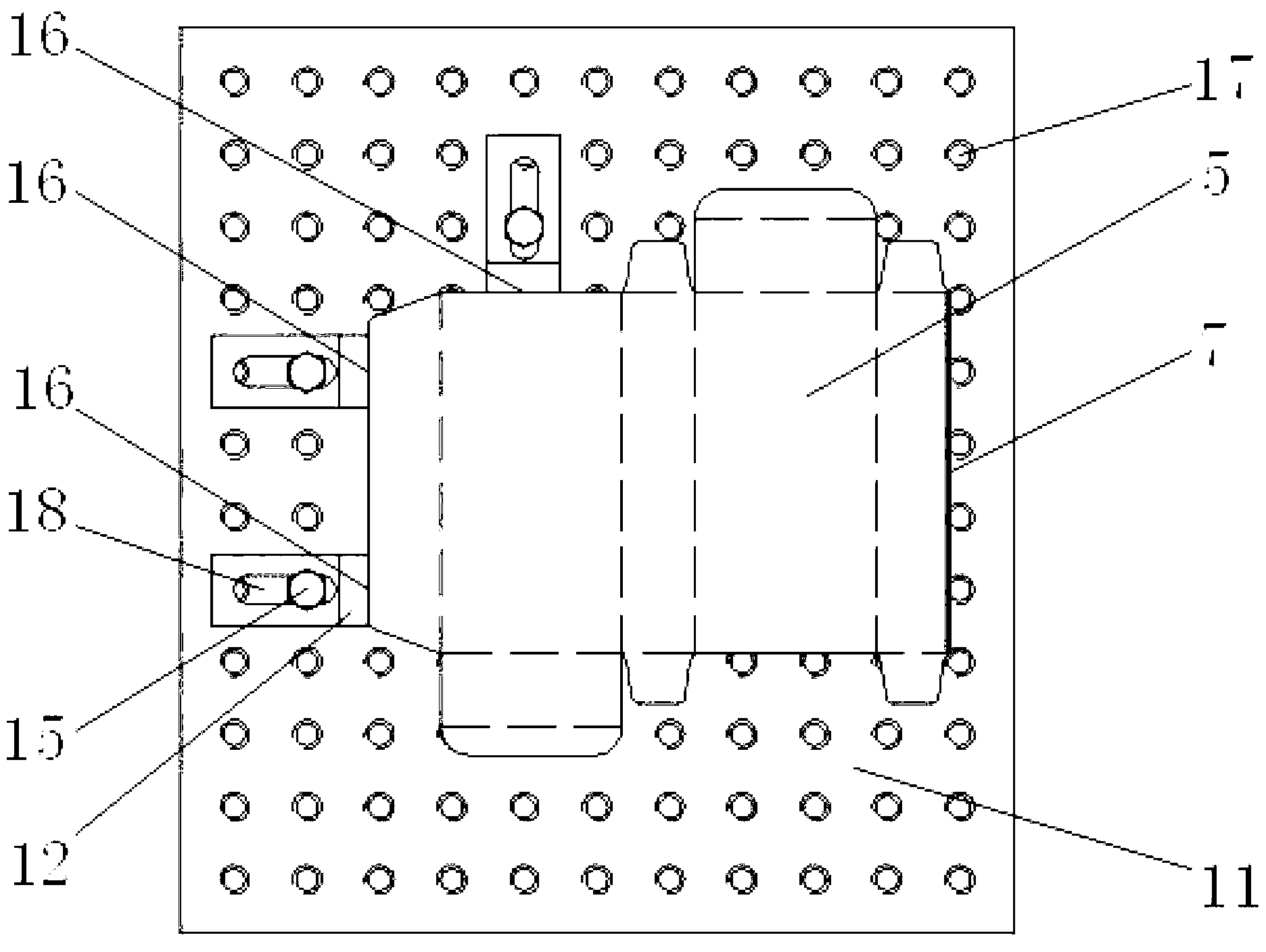

[0017] The stacking device includes a stacking tray, the stacking tray is provided with a positioning tray, the positioning tray is equipped with a positioning bracket, and the positioning tray is provided with a backing plate.

[0018] The positioning tray is provided with a plurality of mounting threaded holes, and the positioning bracket is provided with through holes, and screws are installed on the mounting threaded holes through the through holes.

[0019] The through hole is a long hole, there are multiple positioning brackets, and the lower part ...

specific Embodiment

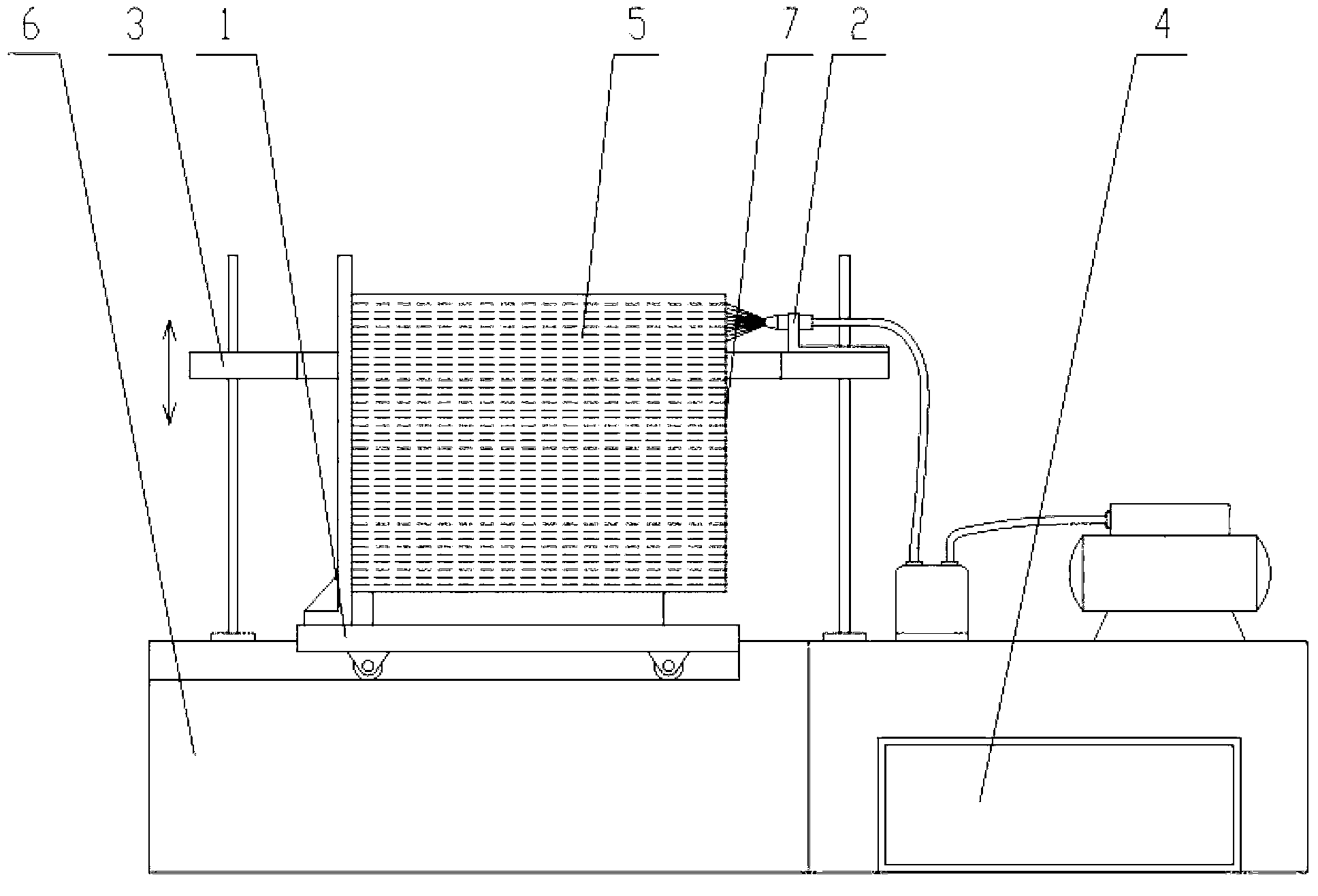

[0025] like figure 1 As shown, it includes a stacking device 1, an inkjet device 2, a lifting device 3 and a control system 4, and its working principle is:

[0026] First, stack and position the boxes 5 with die-cut edges to be colored on the stacking device 1, and then place the stacking device 1 on the machine base 6;

[0027] Open the inkjet device 2, and the high-pressure ink produced by its pressure system is sprayed onto the die-cut edge 7 of the box sheet to be colored through the inkjet nozzle;

[0028] The lifting device 3 drives the inkjet nozzle to reciprocate up and down to ensure that the box 5 can be evenly colored on the part that needs to be colored (the box die-cutting edge 7);

[0029] The control system 4 can control the lifting speed and height of the lifting device 3 and the ink ejection volume of the inkjet device 2 according to the needs of coloring.

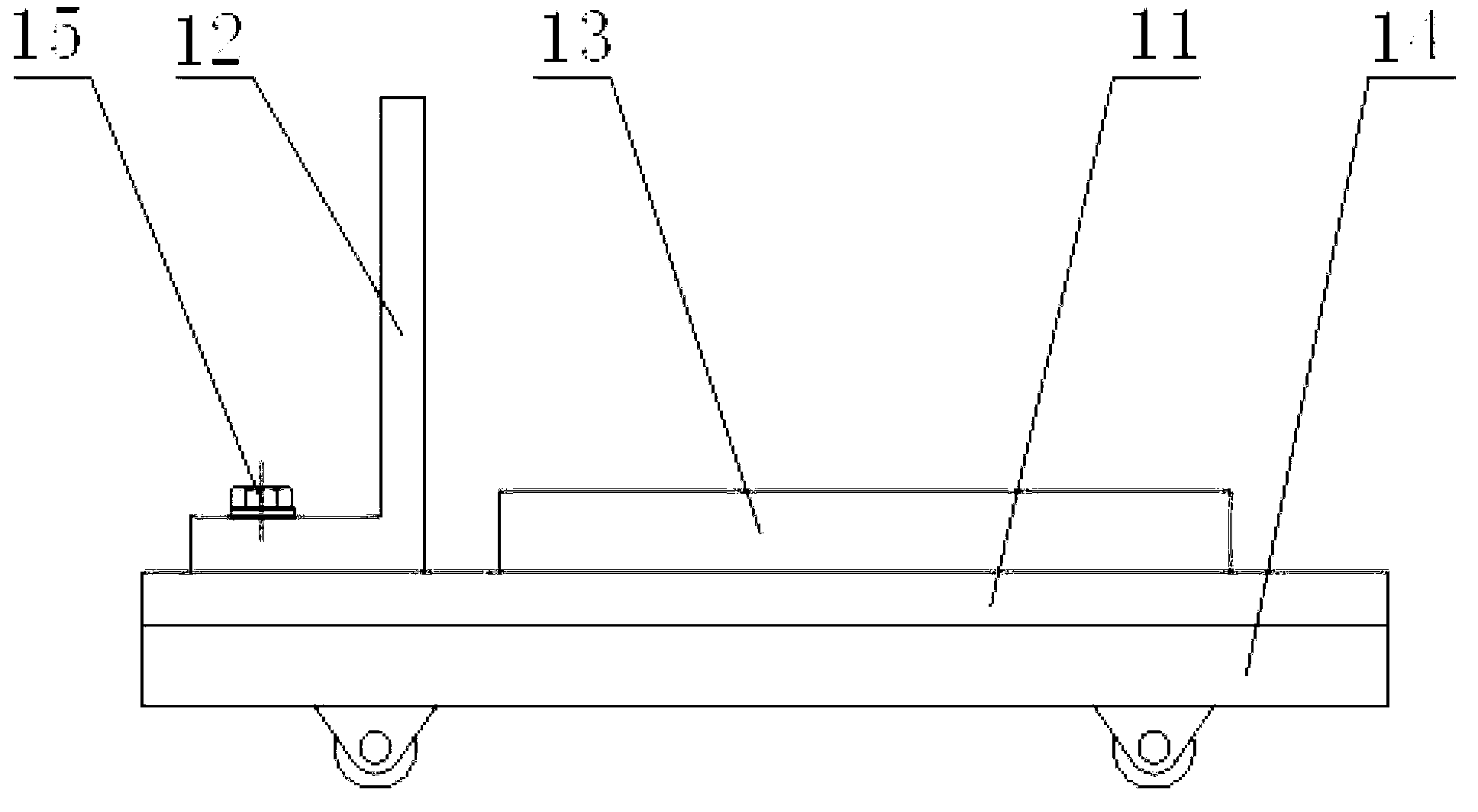

[0030] stacking device such as figure 2 shown, including:

[0031] Positioning tray 11, positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com