One-way moisture-conducting blank-dyed fabric

A technology of one-way moisture guide and moisture guide billet, applied in the textile field, can solve the problem of uniform water repellency effect of the inner and outer yarns of the bobbin, affecting fabric quality and one-way moisture guide effect, poor comfort and air permeability of the inner layer fabric, etc. Problems, to achieve obvious moisture absorption and perspiration effects, good one-way moisture transfer performance, and good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

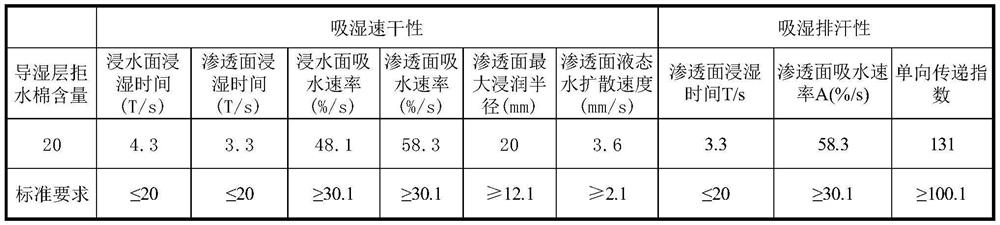

Embodiment 1

[0042] This application discloses a unidirectional moisture-guiding base dyed fabric, the inner layer of which is 100% water-repellent cotton gray yarn. Water-repellent cotton gray yarn is made by mixing water-repellent cotton fiber and ordinary cotton fiber according to the requirements of blended yarn, and then through carding, drawing, roving, spun yarn, winding and other processes. The amount of water-repellent cotton used is 20 wt%.

[0043] Wherein the preparation technology of water-repellent cotton fiber is:

[0044] Refining: the mass ratio of cotton fiber to water is 1:10, the osmotic refining agent containing 1.5g / L and the sodium hydroxide of 4g / L are contained in the described pretreatment aqueous solution, scoured at 98 ℃ for 55 minutes; It is a mixture of fatty acid methyl ester polyoxyethylene ether and sodium dodecylsulfonate at a mass ratio of 1:1;

[0045] Hot wash: hot wash at 85°C for 20 minutes;

[0046] Peracid treatment: the peracid refers to the imp...

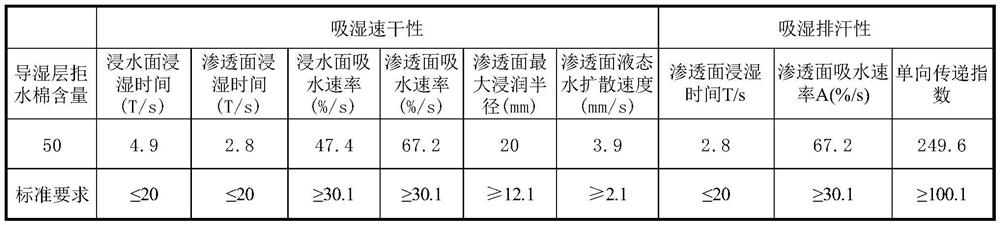

Embodiment 2

[0071] This embodiment discloses a one-way moisture-guiding base dyed fabric, the inner layer of which is 100% water-repellent cotton gray yarn. Water-repellent cotton gray yarn is made by mixing water-repellent cotton fiber and ordinary cotton fiber according to the requirements of blended yarn, and then through carding, drawing, roving, spun yarn, winding and other processes. The amount of water-repellent cotton added is 50wt%.

[0072] Wherein, the preparation technology of water-repellent cotton fiber is:

[0073] Refining: the mass ratio of cotton fiber to water is 1:10; the pretreatment aqueous solution contains 1.5g / L osmotic refining agent and 4g / L sodium hydroxide, and is scoured at 98°C for 55 minutes; the refining agent It is a mixture of fatty acid methyl ester polyoxyethylene ether and sodium dodecylsulfonate at a mass ratio of 1:2;

[0074] Hot wash: hot wash at 85°C for 20 minutes;

[0075] Peracid treatment: the peracid refers to the impregnation treatment w...

Embodiment 3

[0100] In this embodiment, the amount of water-repellent cotton used is 10 wt%, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com