Thermoplastic resin composition with improved heat resistance and coloring property

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin compositions, can solve the problems of poor pigment colorability, insufficient heat resistance, etc., and achieve uniform colorability, improvement of colorability and heat resistance, excellent mechanical properties and The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

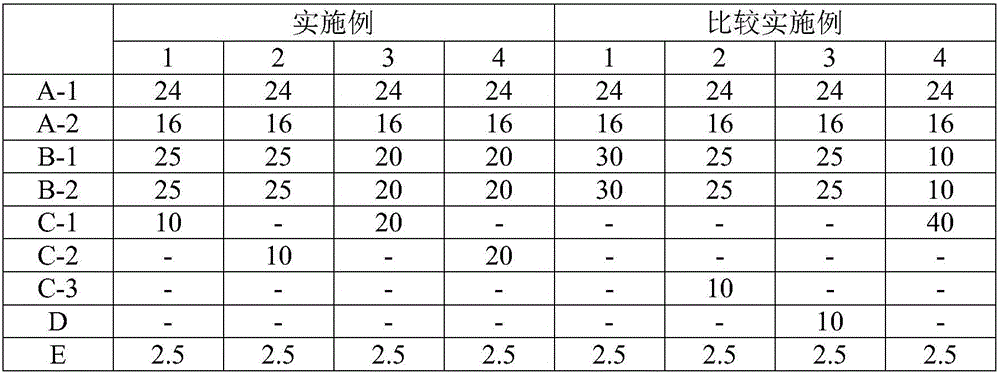

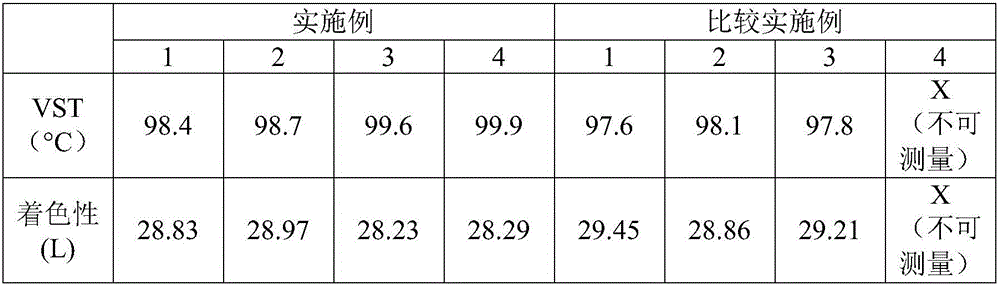

[0117] As shown in Table 1, 2.5 parts by weight of (E) carbon black masterbatch, 0.4 parts by weight of internal lubricant (lubricant (S); HI-LUB B-50), and 1.3 parts by weight of climate stabilizer ( UV stabilizer; LIGHT STABILITYA, UV-327-1) with (A-1) acrylic graft copolymer containing 24wt%, 16wt% (A-2) acrylic graft copolymer, 25wt% (B-1 ) 100 parts by weight of the first aromatic vinyl-vinyl cyanide copolymer, (B-2) the second aromatic vinyl-vinyl cyanide copolymer of 25wt%, and (C-1) acrylic resin of 10wt% The base resin is mixed to prepare a thermoplastic resin.

[0118] The prepared thermoplastic resin was stirred using a typical mixer, followed by extrusion in a twin-screw extruder (L / D = 29, Φ = 45 mm), thereby preparing pellets. The prepared pellets were dried using a dehumidifying drier at 80°C for 2 hours, followed by injection molding using a 60 oz. injection machine at a cylinder temperature of 250°C and a mold temperature of 60°C to prepare 9 cm x 5cm x 0.2c...

Embodiment 2

[0120] As shown in Table 1, samples for property evaluation were prepared in the same manner as in Example 1, except that (C-2) acrylic resin having a glass transition temperature of 116° C. was used instead of (C-1) acrylic resin. The following properties of the prepared samples were evaluated, and the results are shown in Table 2.

Embodiment 3

[0122] As shown in Table 1, samples for property evaluation were prepared in the same manner as in Example 1 except that the (C-1) acrylic resin was used in an amount of 20 parts by weight. The following properties of the prepared samples were evaluated, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com