Color matching method of micro-encapsulation disperse dyes

A technology of disperse dyes and microencapsulation, which is applied in dyeing methods, microcapsule preparations, microsphere preparations, etc., can solve the problems of not being able to meet the multi-color requirements of fabrics, and achieve the effects of energy saving, firm coloring, and low dyeing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

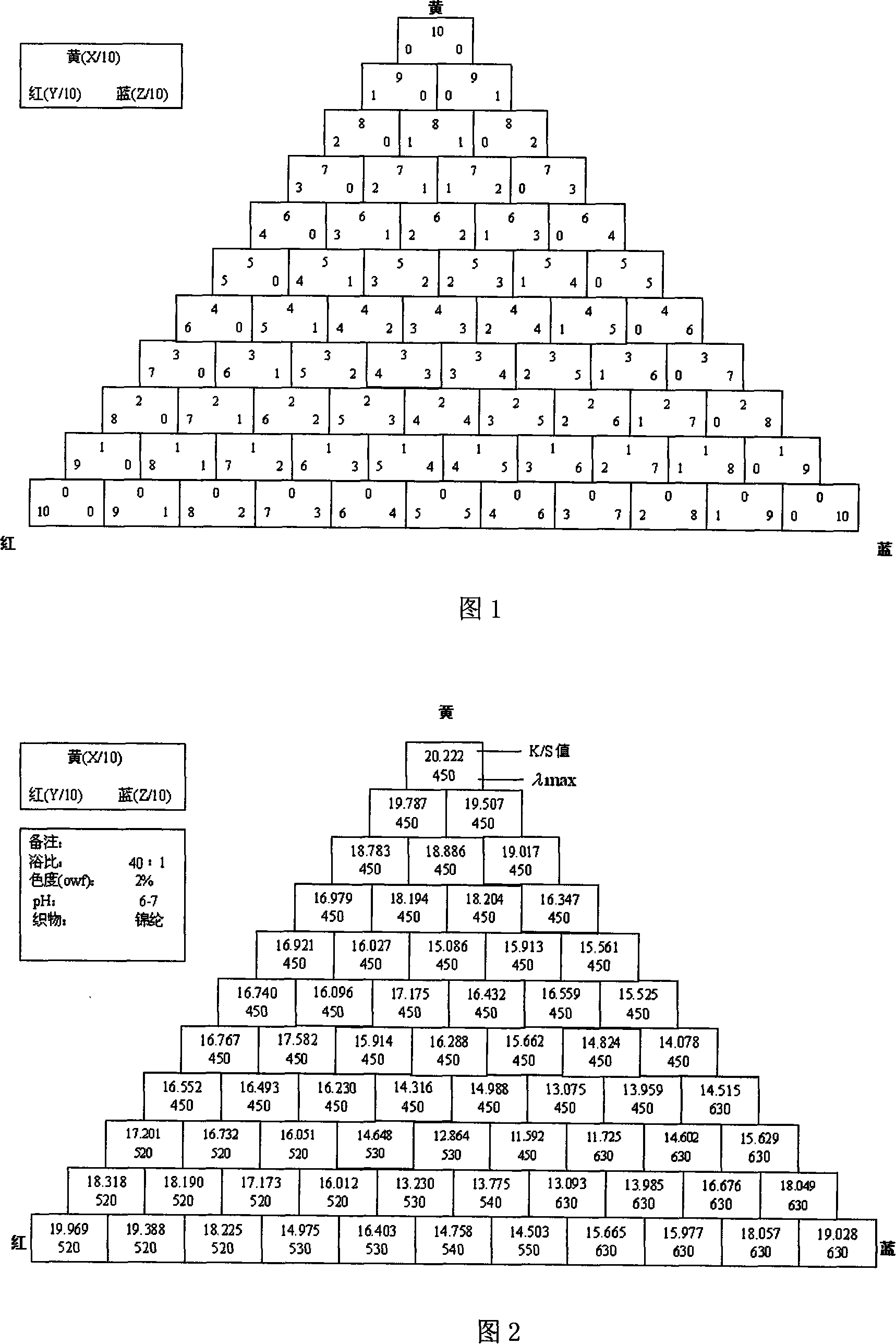

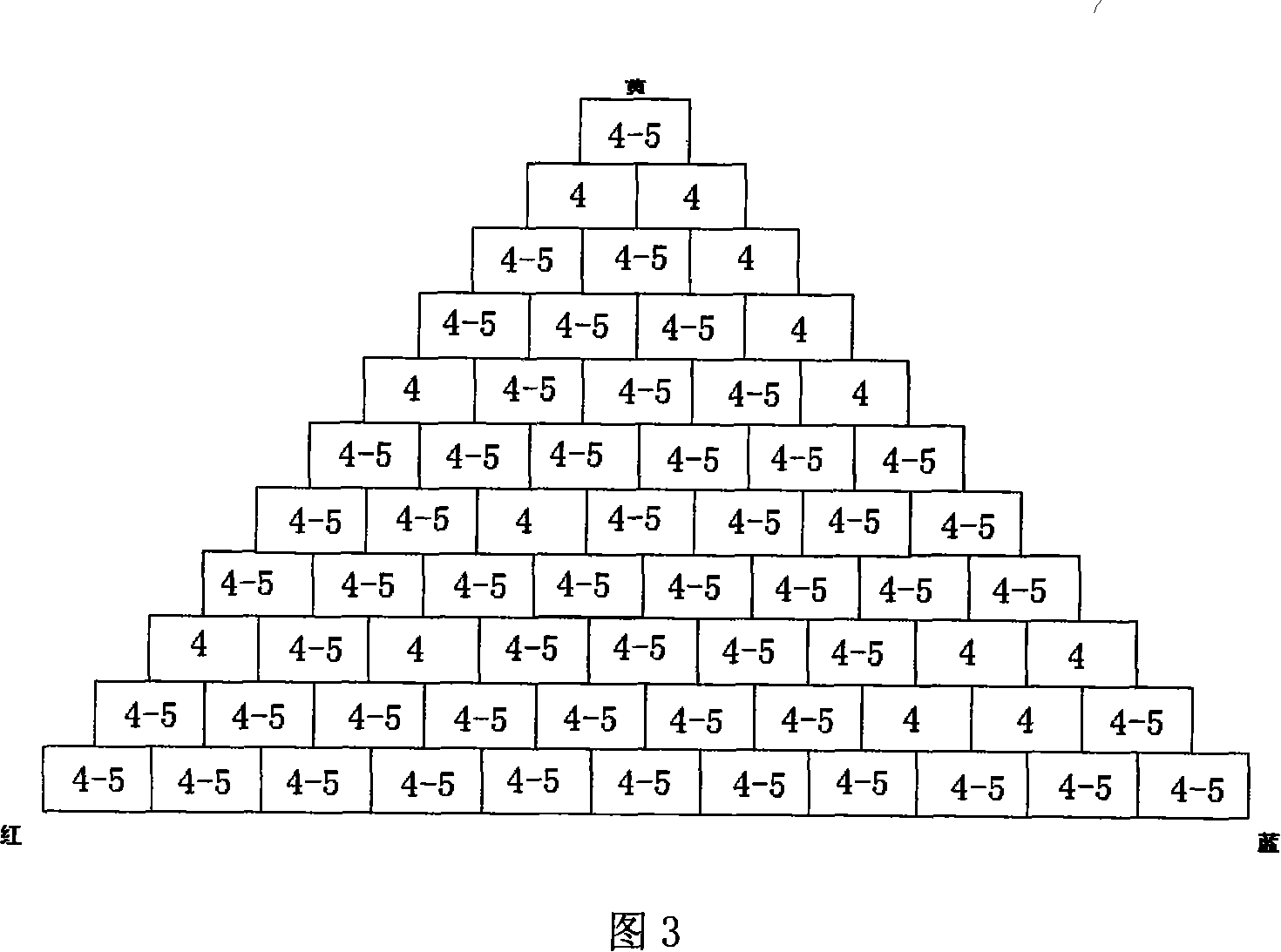

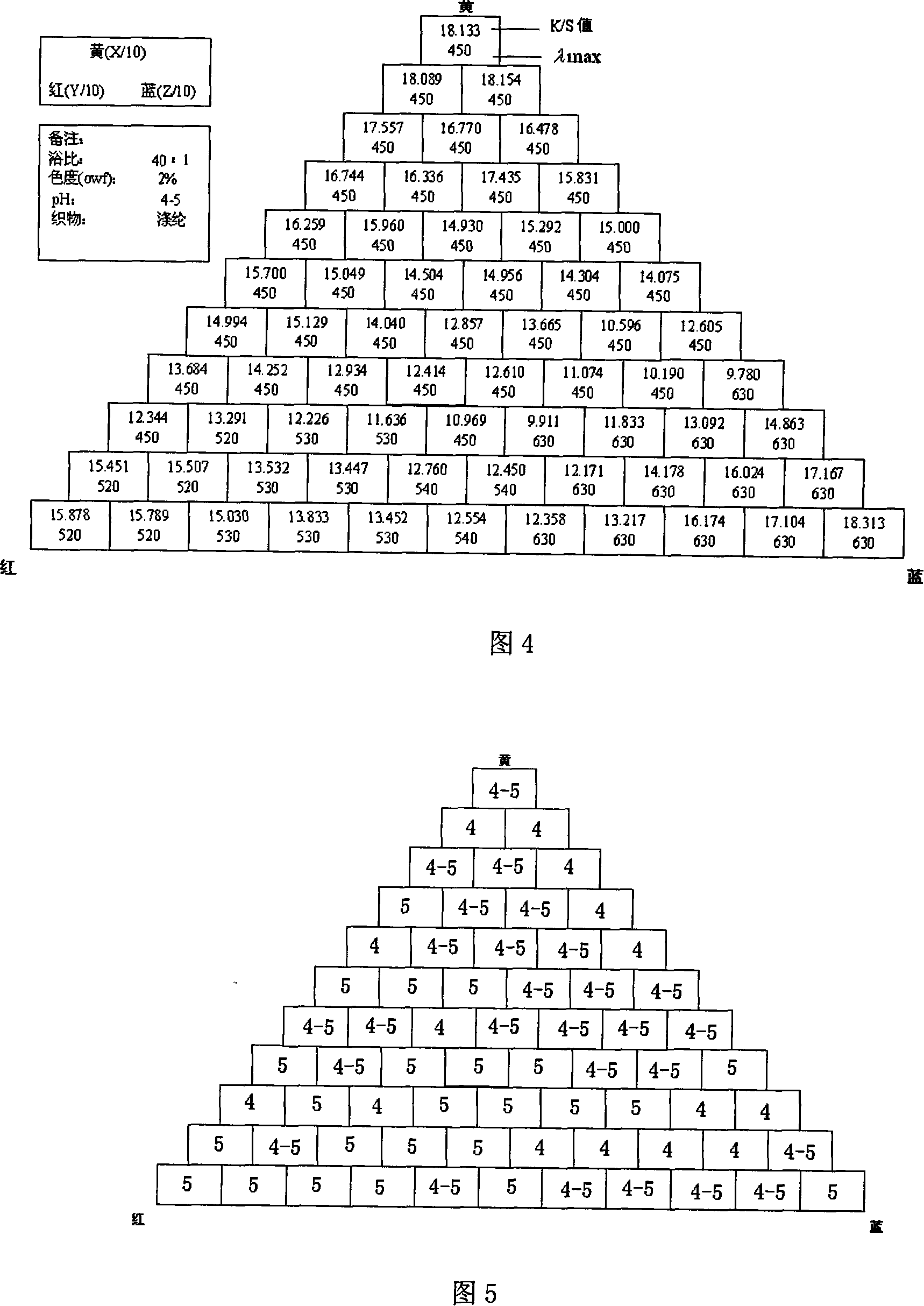

Embodiment 1

[0020] Weigh 5g of nylon 66, put disperse dye microcapsules (core-wall ratio CW=1:1) into the dyeing bath by 2% of the fabric weight, disperse dye microcapsules C.I. disperse red 60, C.I. disperse yellow 54, C.I. disperse blue 56 The dosage of the three primary colors is according to the ratio of the color tower diagram shown in Figure 1. Adjust the pH of the dye solution with acetic acid to 6~7, enter the dyeing at 40°C, raise the temperature to 100°C, and dye for 40 minutes, then quickly cool down to 60°C. Take out the fabric, filter the dye solution and then pour it into the dyeing cup, put the taken out fabric into the solution, raise the temperature to 80°C, keep it warm for 10 minutes, cool down, take out the fabric, wash it in cold water, and dry it in the air. The K / S values of the dyed fabric at different wavelengths measured by the Datacolor SF600 Plus CT color measuring and matching instrument produced in Switzerland are shown in Figure 2. The washing fastness of ...

Embodiment 2

[0023] Weigh 5g of polyester fabric, put disperse dye microcapsules (CW=1:3) into the dyeing bath by 6% (omf) of fabric weight, disperse dye microcapsules C.I. Disperse Red 60, C.I. Disperse Yellow 54, C.I. Disperse Blue 56 The amount of the three primary colors is matched according to the color tower diagram, the pH of the dyeing solution is adjusted to 4~5 with acetic acid, the dyeing is carried out at 10°C, the temperature is raised to 130°C, the dyeing time is 30min, and then the temperature is quickly cooled to 60°C. Take out the fabric, filter the dye solution and then pour it into the dyeing cup, put the taken out fabric into the solution, raise the temperature to 70°C, keep it warm for 15 minutes, cool down, take out the fabric, wash it with tap water, and dry it. The K / S values of the dyed fabric at different wavelengths measured by the Datacolor SF600 Plus CT color measuring and matching instrument made in Switzerland are shown in Figure 4. The washing fastness of ...

Embodiment 3

[0026] Weigh 5g of polyester fabric, put disperse dye microcapsules (CW=1:2) into the dyeing bath by 10% (omf) of fabric weight, disperse dye microcapsules C.I. Disperse Red 73, C.I. Disperse Yellow 211, C.I. Disperse Blue 183 The dosage ratio of the three primary colors is 4:5:1, the pH of the dye solution is adjusted to 4-5 with hydrochloric acid, the dyeing is carried out at 20°C, the temperature is raised to 85°C, the dyeing time is 50min, and then the temperature is rapidly lowered to 60°C. Take out the fabric, pour the dyeing solution into the dyeing cup after filtering, put the taken out fabric into the solution, raise the temperature to 85°C, keep it warm for 20 minutes, cool down, take out the fabric, wash it fully with tap water, and dry it in the air. The K / S value measured at λ=450nm by Datacolor SF600 PlusCT color measuring and matching instrument is 16.004. The washing fastness of the fabric is grade 5, the light fastness is grade 6-7, and the wet and dry frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com