Stainless steel electrochemical colouring method

A stainless steel and electrochemical technology, applied in the field of stainless steel electrochemical coloring, can solve the problems of affecting the health of workers, central nervous system toxicity, and rapid failure of the treatment solution, and achieve the effects of stable color, health benefits and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

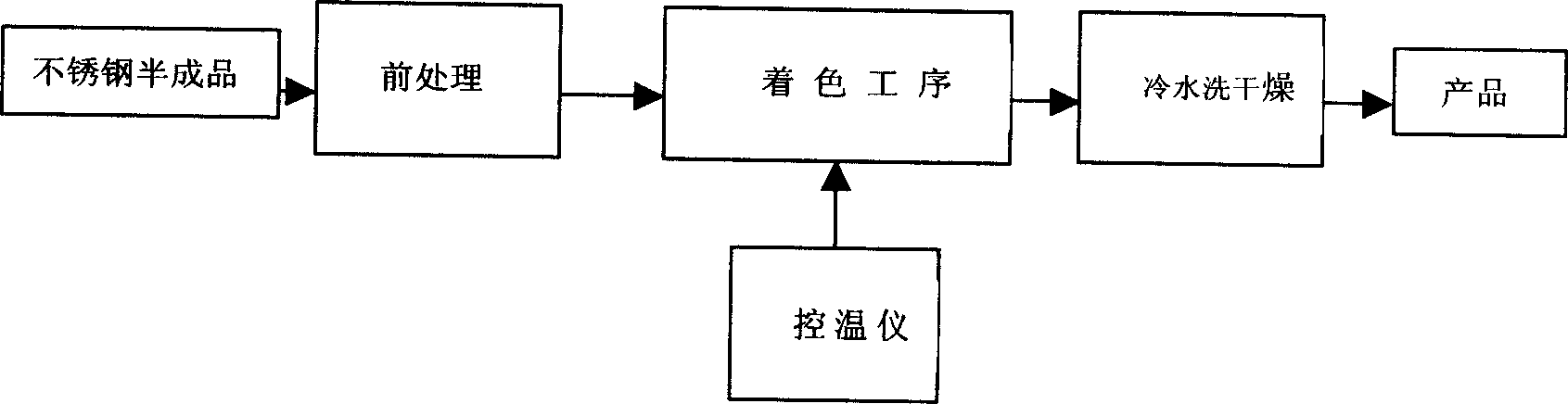

[0027] The first step is to pre-treat the 1Cr18Ni9 austenitic stainless steel plate for decoration, including degreasing; hot water washing; flowing cold water washing; activation; flowing cold water washing;

[0028] The second step is to place the coloring solution in the electrolytic cell, place the stainless steel semi-finished product in the coloring solution for coloring treatment, the anode is stainless steel, and the cathode is the colored stainless steel semi-finished product. Control coloring current 0.06A / dm 2 ;The electrolytic coloring time is 4 minutes; heated to the required coloring temperature of 42°C in a constant temperature water bath (controlled by a temperature controller); the coloring solution is an aqueous molybdate solution with a content of 25g / L, and dihydrogen phosphate is added at 12.5g / L salt, adjust the pH of the coloring solution to 6.5 with sulfuric acid;

[0029] The third step is to wash the colored stainless steel semi-finished products in ...

Embodiment 2

[0035] Electrochemical coloring was carried out according to the process conditions of Example 1. When the coloring time is 7.0 minutes, the color obtained is uniform and bright brown; when the coloring time is 10.0 minutes, the color obtained is uniform and bright brown-black; when the coloring time is 15.0 minutes, the color obtained is uniform and bright Jet black; when the coloring time is 60.0 minutes, the color obtained is uniform and bright deep black. The film layer is rubbed with an eraser at a 45° angle, and it will not fade after more than 1500 times, and the more you rub it, the brighter it is.

Embodiment 3

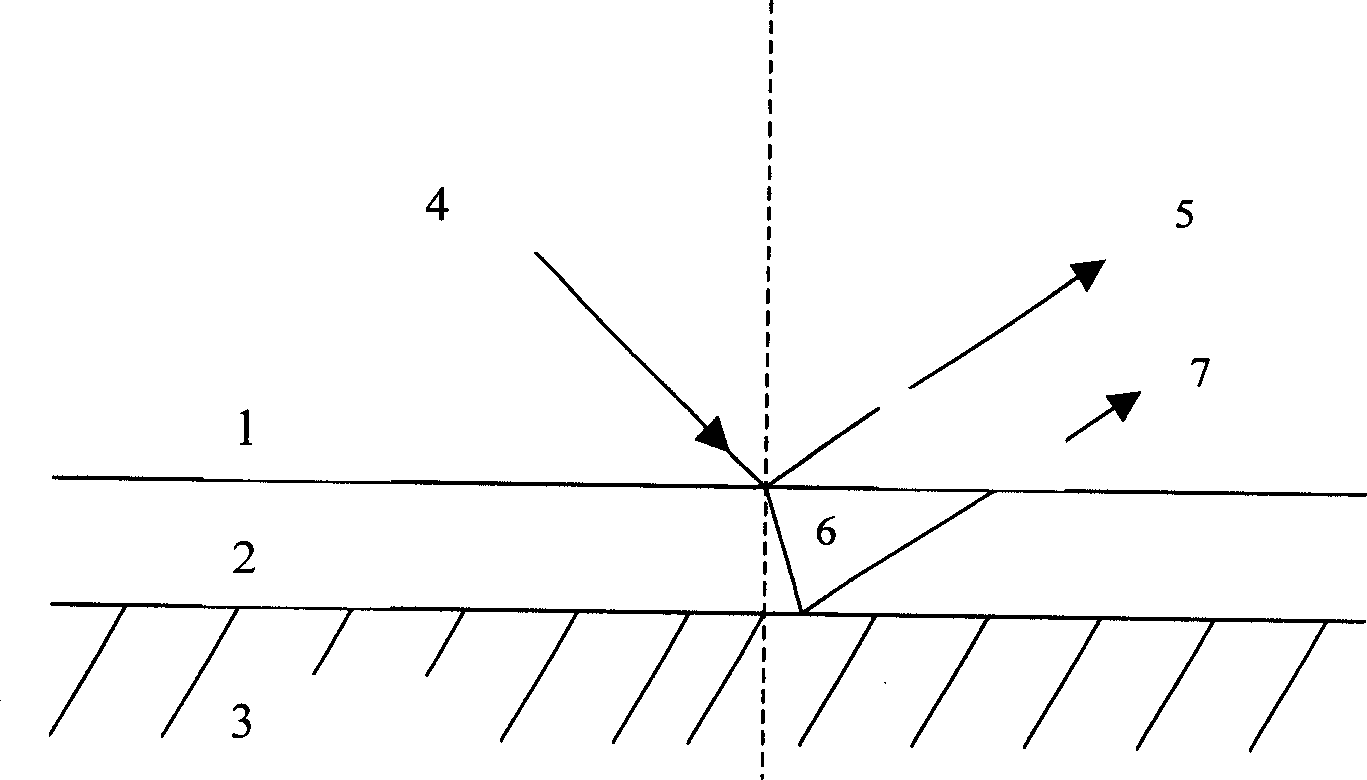

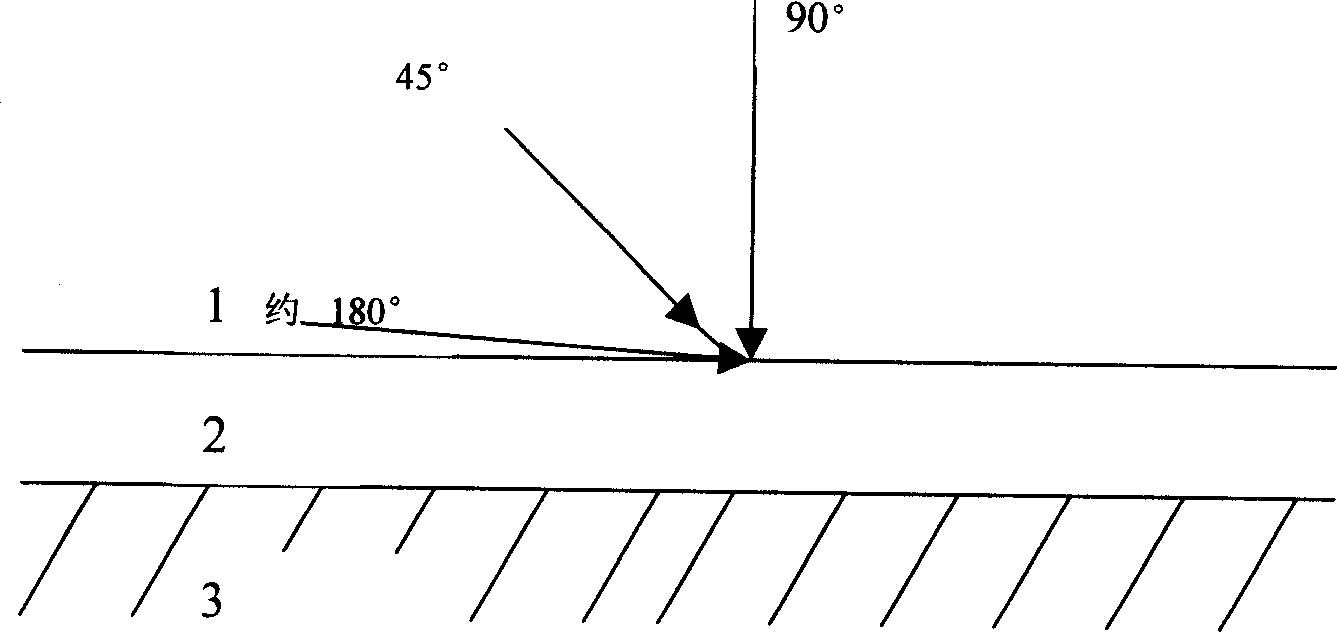

[0037] Adjust coloring current density to 0.10A / dm 2, and the rest are electrochemically colored according to the process conditions of Example 1. When the coloring time is 10 seconds, a uniform and bright blue-purple color is obtained; when the coloring time is 20 seconds, a uniform and bright silver gray is obtained; when the coloring time is 30 seconds, a uniform and bright golden yellow is obtained; when the coloring time is 40 seconds , Obtain a uniform and bright color interference film, which is yellow-green when viewed vertically, blue when viewed at an angle of 45°, and purple when viewed horizontally at about 180°; when the coloring time is 50 seconds, a uniform and bright color interference film is obtained, and when viewed vertically It is golden yellow, blue when observed at a 45° angle, and purple when viewed horizontally at about 180°. It can be seen that the color types of the coloring are more than those of the conventional coloring, and the uniformity and br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com