A kind of reactive dye exhaust dyeing process of cotton fabric

A technology for reactive dyes and cotton fabrics, applied in the field of dyeing, can solve the problems of many cationic modification treatment steps, large amount of cations, restricting large-scale use, etc., and achieves improved dyeing rate and color fixation rate, and good color fastness to washing. , the effect of reducing the amount of dyeing wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

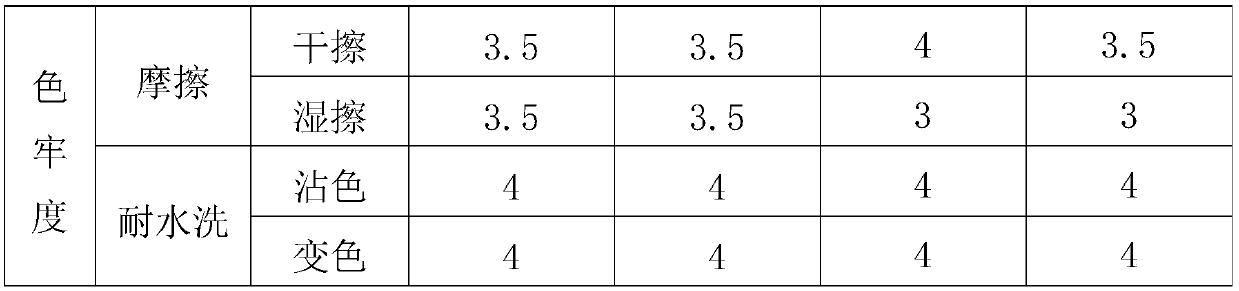

Examples

Embodiment 1

[0021] In the present embodiment, a kind of reactive dye exhaust dyeing process of cotton fabric comprises the following steps:

[0022] S1, pretreatment, configure the bleaching solution, the bleaching solution includes: refining agent 1g / L, caustic soda 6g / L, hydrogen peroxide 3g / L, hydrogen peroxide stabilizer 1g / L, put the cotton fabric in according to the bath ratio of 1:10 Put it into the blanching liquid, treat it at 115°C for 5 minutes, and then use the enzyme washing liquid to carry out enzyme washing at 55°C. The enzyme washing liquid includes: pectinase 0.5g / L, cellulase 2g / L, glacial acetic acid 0.5g / L, and finally carry out shaping treatment, the shaping temperature is 160°C, and the speed is 20m / min;

[0023] S2, dyeing, immerse the cotton fabric after S1 pretreatment in the reactive dye solution, the reactive dye solution is formed by adding 0.5g / L reactive dye into water and dehydrated alcohol with a volume ratio of 1:10 obtained from the mixed solution, adju...

Embodiment 2

[0026] In the present embodiment, a kind of reactive dye exhaust dyeing process of cotton fabric comprises the following steps:

[0027] S1, pretreatment, configure the bleaching solution, the bleaching solution includes: refining agent 2g / L, caustic soda 2g / L, hydrogen peroxide 8g / L, hydrogen peroxide stabilizer 0.5g / L, according to the bath ratio of 1:15 cotton fabric Put it into the bleaching solution, treat it at 105°C for 30 minutes, and then use the enzyme washing solution to perform enzyme washing at 45°C. The enzyme washing solution includes: pectinase 1g / L, cellulase 1g / L, glacial acetic acid 1g / L L, the final setting treatment, the setting temperature is 150 ℃, and the speed is 30m / min;

[0028]S2, dyeing, immerse the cotton fabric after S1 pretreatment in reactive dye solution, described reactive dye solution is the mixing that the reactive dye of 2.5g / L is added into the water and acetone that volume ratio is 1:5 to form Obtained from the solution, adjust the bath...

Embodiment 3

[0031] In the present embodiment, a kind of reactive dye exhaust dyeing process of cotton fabric comprises the following steps:

[0032] S1, pretreatment, configure the bleaching solution, the bleaching solution includes: refining agent 1.5g / L, caustic soda 4g / L, hydrogen peroxide 5g / L, hydrogen peroxide stabilizer 0.7g / L, according to the liquor ratio of 1:12 cotton Put the fabric into the bleaching solution, treat it at 110°C for 15 minutes, and then use the enzyme washing liquid to carry out enzyme washing at 50°C. The enzyme washing liquid includes: pectinase 0.7g / L, cellulase 1.5g / L, ice Acetic acid 0.8g / L, final setting treatment, setting temperature is 155 ℃, speed is 25m / min;

[0033] S2, dyeing, immerse the cotton fabric after S1 pretreatment in reactive dye solution, described reactive dye solution is to form by adding the reactive dye of 1.5g / L volume ratio to be 1:7 water and dehydrated alcohol obtained from the mixed solution, adjust the bath ratio to 1:15, enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com