Extraction method of microbial pigment and method for dyeing lyocell fibers by adopting same

A technology of microbial pigment and extraction method, which is applied in the field of lyocell fiber dyeing and microbial pigment extraction, can solve the problems of poor compatibility, difficulty in attaching microbial pigment to its surface, weakening dyeing efficiency, etc., and achieve low production cost, solid Good color effect, reduced dry rubbing fastness and soaping fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

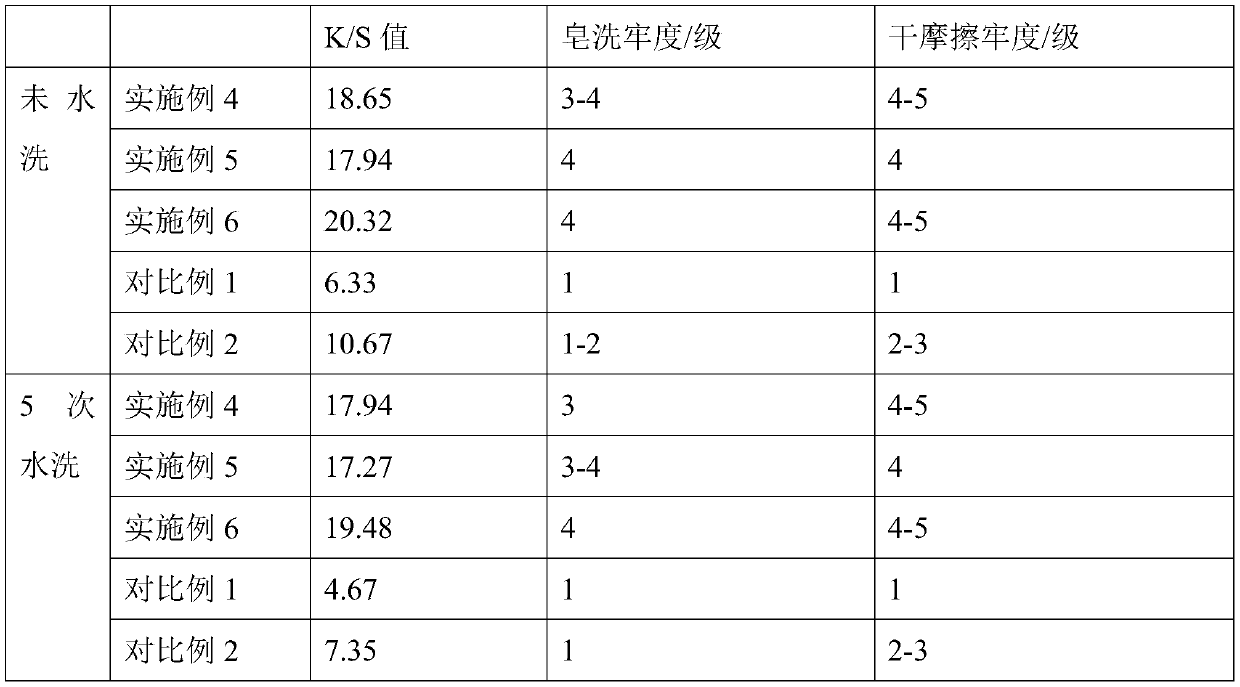

Examples

Embodiment 1

[0036] Fusarium was used as raw material to extract the red pigment.

[0037] 1) Inoculate the purchased Fusarium into the seed culture solution and cultivate it on a shaker at a temperature of 20-30°C for 16 hours and a shaker speed of 130r / min; the seed culture solution includes 3g / L yeast powder , 5g / L peptone, 2g / L sodium chloride, 2g / L potassium chloride.

[0038] 2) Inoculate the bacterial seed solution into the fermentation medium and cultivate it on a shaker; the culture temperature is 20-30°C, the time is 36 hours, and the shaker speed is 195r / min; the fermentation medium includes peptone 15g / L, 0.3% propylene glycol , 2g / L magnesium sulfate, 2g / L sodium chloride, 1g / L potassium chloride.

[0039] 3) After the fermentation, use a centrifuge to centrifuge the fermentation broth at 8000r / min for 6 minutes; then extract the centrifuged product with ethyl acetate; concentrate and dry the extract to obtain a red pigment powder.

Embodiment 2

[0041] Using Chryseobacterium as raw material, the yellow pigment is extracted.

[0042] 1) Inoculate the purchased Chryseobacterium into the seed culture solution and cultivate it on a shaker at a temperature of 20-30°C for 18 hours and a shaker speed of 120r / min; the seed culture solution includes 4g / L yeast powder, 8g / L peptone, 3g / L sodium chloride, 4g / L potassium chloride.

[0043] 2) Inoculate the bacterial seed solution into the fermentation medium and cultivate it on a shaker; the culture temperature is 20-30°C, the time is 50 hours, and the shaker speed is 150r / min; the fermentation medium includes peptone 17g / L, 0.4% propylene glycol , 4g / L magnesium sulfate, 4g / L sodium chloride, 2g / L potassium chloride.

[0044] 3) After the fermentation, use a centrifuge to centrifuge the fermentation broth at 8000r / min for 8 minutes; then extract the centrifuged product with ethyl acetate; concentrate and dry the extract to obtain a yellow pigment powder.

Embodiment 3

[0046] Violet bacillus is used as raw material to extract the purple pigment.

[0047] 1) Inoculate the purchased violaceum bacillus into the seed culture solution and then cultivate it on a shaker at a temperature of 20-30°C for 20 hours and a shaker speed of 150r / min; the seed culture solution includes 5g / L yeast powder, 10g / L peptone, 3g / L sodium chloride, 4g / L potassium chloride.

[0048] 2) Inoculate the bacterial seed solution into the fermentation medium and cultivate it on a shaker; the culture temperature is 20-30°C, the time is 70h, and the shaker speed is 180r / min; the fermentation medium includes peptone 20g / L, 0.5% propylene glycol , 3g / L magnesium sulfate, 3g / L sodium chloride, 1g / L potassium chloride, and the rest water.

[0049] 3) After the fermentation, use a centrifuge to centrifuge the fermentation broth at 10,000 r / min for 5 minutes; then extract the centrifuged product with ethyl acetate; concentrate and dry the extract to obtain a purple pigment powder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com