Disperse dye composition and disperse dye and preparation method and application thereof

A technology for disperse dyes and compositions, applied in the field of dyes, to achieve the effects of less pollution, low cost and excellent perspiration fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

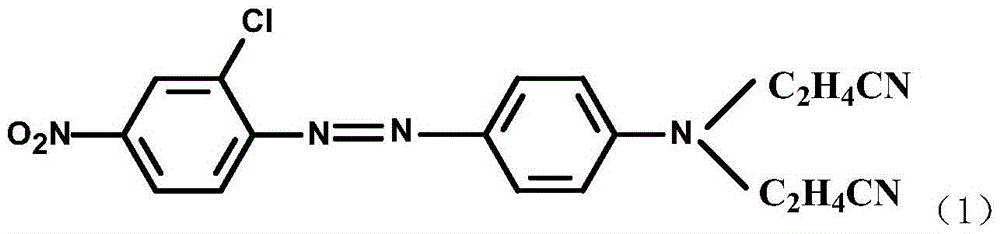

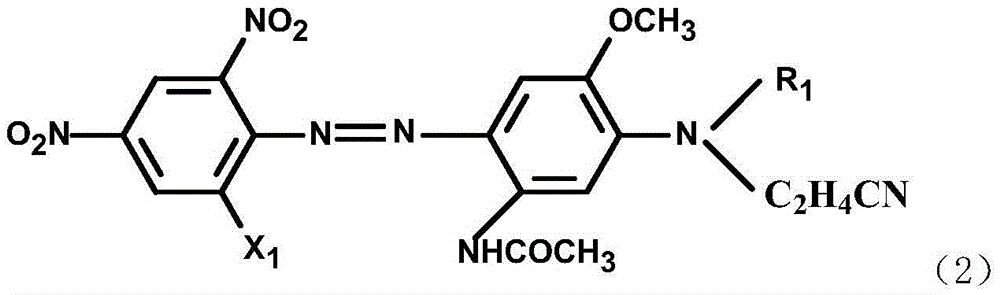

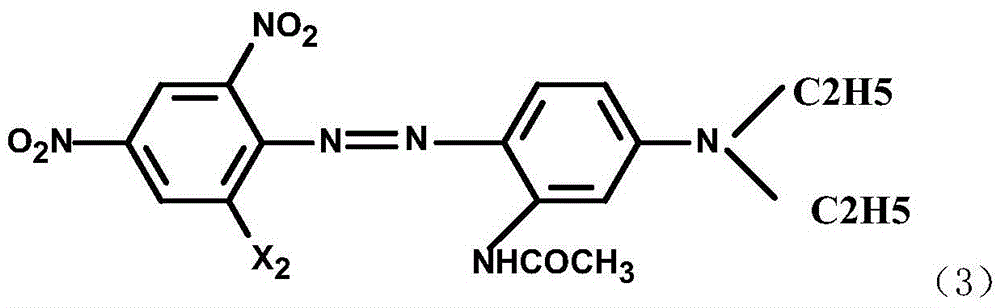

[0043] 37 grams of the dye component of formula (1), 53 grams of the dye component of formula (2-2), 10 grams of the dye component of formula (3-2), 100 grams of lignin 83A, and 300 grams of water are added and stirred evenly , grind, disperse and dry to obtain a black disperse dye, which has excellent fastness properties on polyester fiber dyed fabrics.

Embodiment 2-10

[0053] According to the composition formulation in Table 2, disperse dyes were made in the same manner as in Example 1. Wherein, the amount of moisture in Table 2 is the moisture weight of the final disperse dye.

[0054] Table 2

[0055]

[0056]

[0057] The method in Example 1 was used to test the sublimation fastness, color fastness to washing and perspiration fastness of the disperse dyes prepared in Examples 2-12, and the results are shown in Table 3.

[0058] Table 3 Unit Level

[0059]

[0060]

[0061] The test results show that the disperse dye of the invention has excellent fastness properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com