Supercritical CO2 fluid dye composition for textile, dyeing system and method

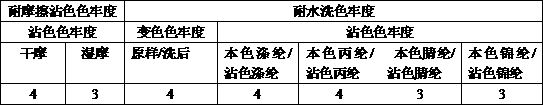

A dye composition and dyeing system technology, applied in the field of anhydrous dyeing of textiles, can solve problems such as no literature report and practical application, few research on color combination, etc., and achieve excellent color fastness to washing, good dyeing effect, Avoid the effect of competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

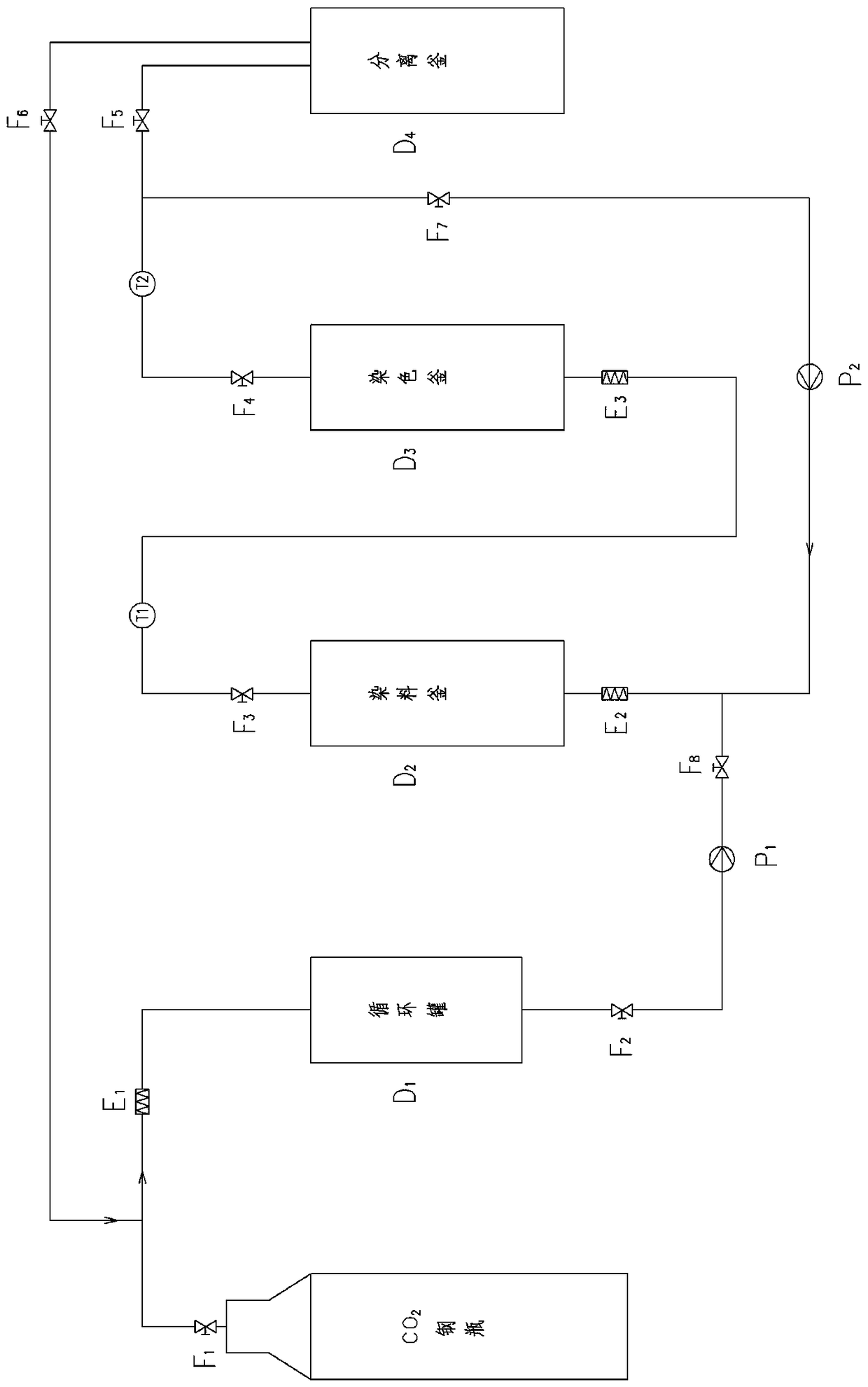

[0028] A textile with supercritical CO 2 The dyeing system of the fluid dye composition comprises a carbon dioxide steel cylinder connected in sequence, a heat exchanger E1, a circulation tank D1, a booster pump D2, a dye kettle D3, a dyeing kettle D4, and a separation kettle D5, and the fluid outlet of the dyeing kettle D4 is connected to the A circulating pump P2 is also arranged between the fluid inlets of the dye tank D3.

[0029] A carbon dioxide loop is also provided between the carbon dioxide outlet of the separation tank D5 and the carbon dioxide inlet of the heat exchanger E1. A heat exchanger is connected to the fluid inlet of the dye kettle D3 and the fluid inlet of the dye kettle D4, and a detector of an online monitor is also connected to the fluid outlet of the dye kettle D3 and the fluid outlet of the dye kettle D4.

Embodiment 2

[0031] Utilize the method that embodiment 1 dyeing system carries out dyeing, concrete technological process is:

[0032] (1) Loading and pressurization: put the textiles into the dyeing kettle, put the above-mentioned dyes mixed evenly into the dyeing kettle, connect the whole dyeing system, and fill the carbon dioxide through the booster pump (pressurized to 20~28Mpa), At the same time, control the temperature and pressure of the dyeing kettle and dyeing kettle to reach the preset value (20~28Mpa, temperature 110~180℃);

[0033] (2) Dyeing and leveling: close the valves of the booster pump and the separation tank, turn on the circulation pump, and start dyeing, so that the fluid circulates between the dye tank and the dye tank; at the same time, the change of the dye ratio during the dyeing process is detected online until the dyeing process is completed. complete;

[0034] (3) Residual dye recovery: After the dyeing is completed, the system gradually cools down; when the t...

Embodiment 3

[0037] The compatibility of disperse dyes is mainly determined by the lifting power and dyeing rate of dyes. In order to avoid the phenomenon of "competitive dyeing", when we screen three-color dyes, we must require good compatibility of the three dyes. Utilize embodiment 2 dyeing method to carry out the screening of three primary color disperse dyes:

[0038] The concentrations of the three dyes are represented by x, y, and z respectively, and the deviation is represented by P; the concentration ratio at the entrance of the dyeing kettle is: x 1 :y 1 :z 1 , the ratio to x is (x 1 / x 1 ):(y 1 / x 1 ):(z 1 / x 1 )=1:(y 1 / x 1 ):(z 1 / x 1 ); The concentration ratio of dyeing kettle outlet is: x 2 :y 2 :z 2 , the ratio relative to x is: 1:(y 2 / x 2 ):(z 2 / x 2 ).

[0039] The proportional deviation of the first set of test data P=(y 2 / x 2 -y 1 / x 1 ) 2 +(z 2 / x 2 -z 1 / x 1 ) 2 , the deviation is 0, indicating that no competition occurs at all, the sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com