Patents

Literature

53 results about "Dye recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

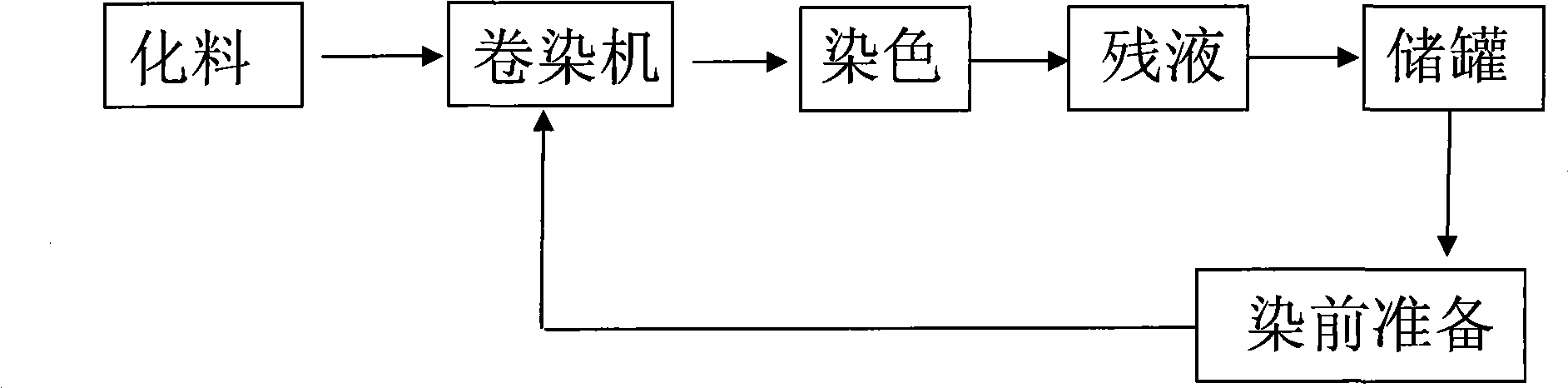

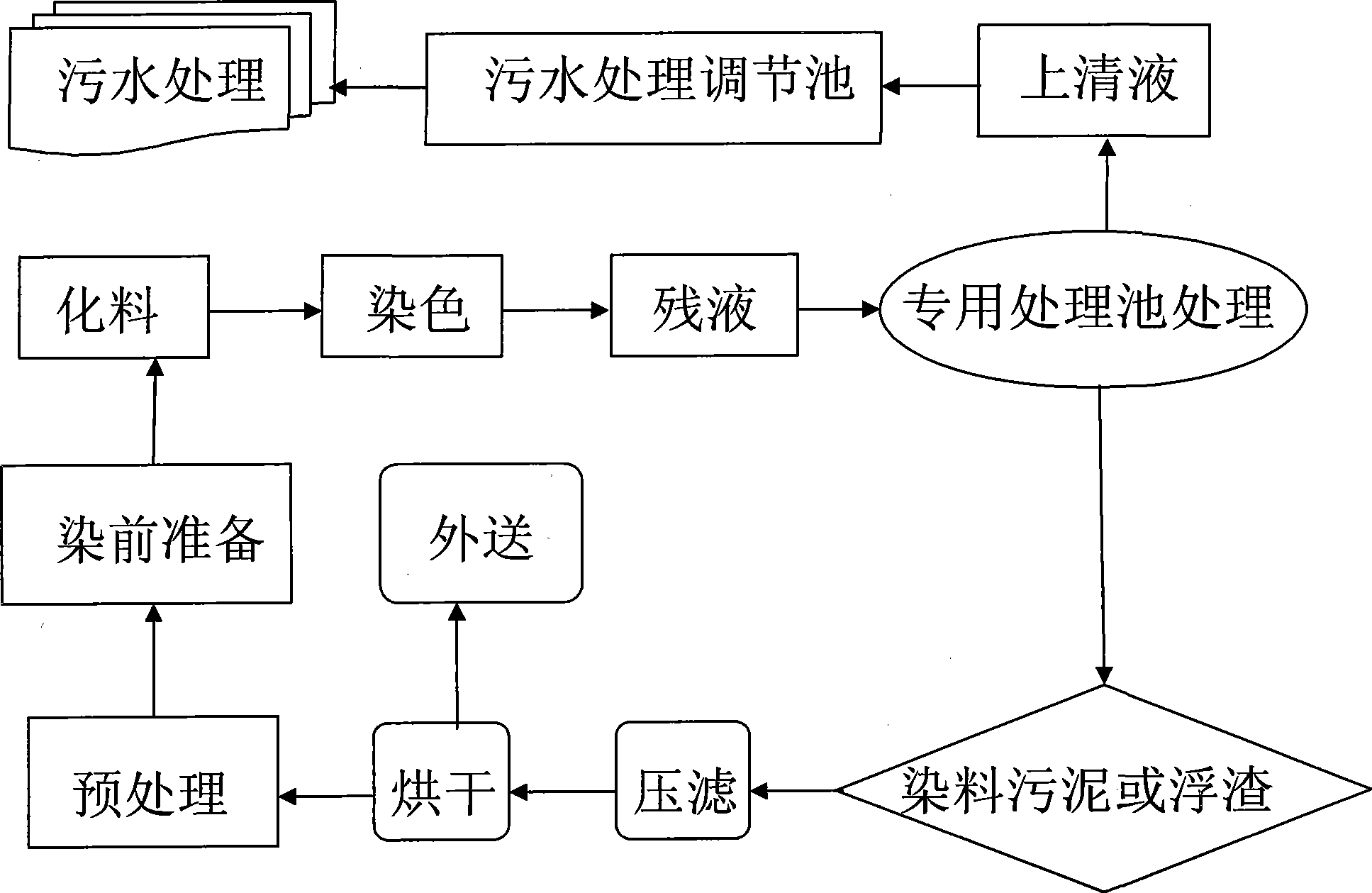

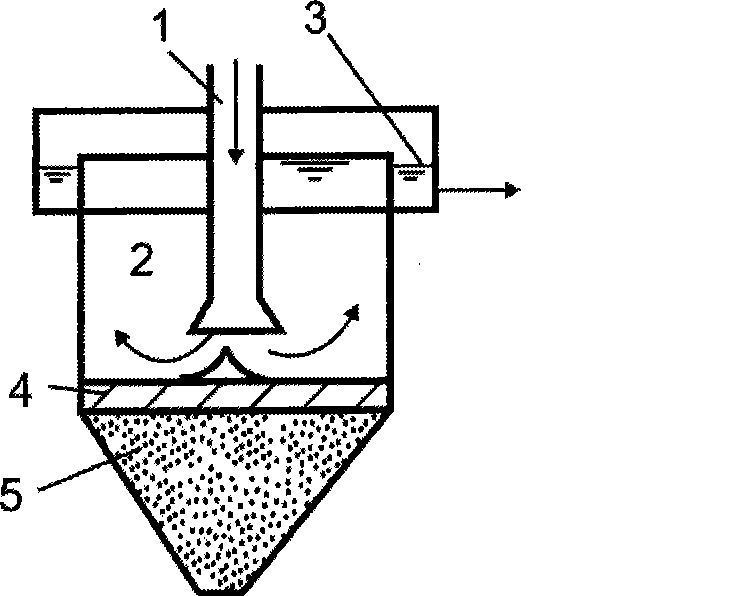

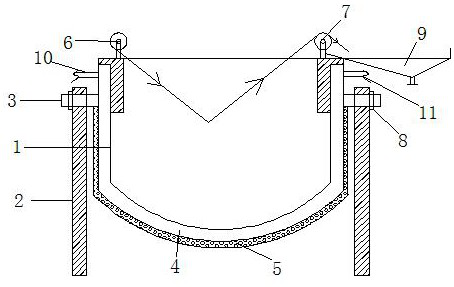

Dyeing residual liquid recycling and dye recovery processing method, and special dyeing residual liquid processing pool

InactiveCN101475227AReduce CODReduce chromaDyeing processWaste water treatment from textile industryTreatment pondCellulose fiber

The invention relates to a method for reusing dyeing raffinate of cellulosic fiber dye, recovering and treating dye, as well as a structure of a special dyeing raffinate treatment pond. According to different dyeing methods and different application categories of dyes, typical basic dyes are selected, and the maximum absorption wavelength or characteristic wavelength of each basic dye is sought so as to determine the content of each blended dye in raffinate and reuse the raffinate in production, while the dyeing raffinate which cannot be directly used in production is recovered through a special treatment pond and a corresponding method. The invention solves the technical problems that the prior art cannot directly reuse the dyeing raffinate in production, cannot recover the dyes in the dyeing raffinate, and has no special treatment device and equipment for recovering and reusing the dyes.

Owner:CHANGZHOU TEXTILE GARMENT INST

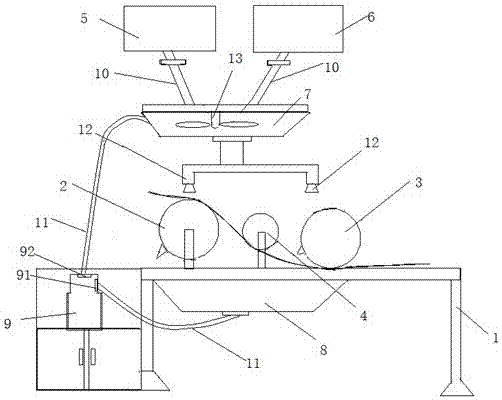

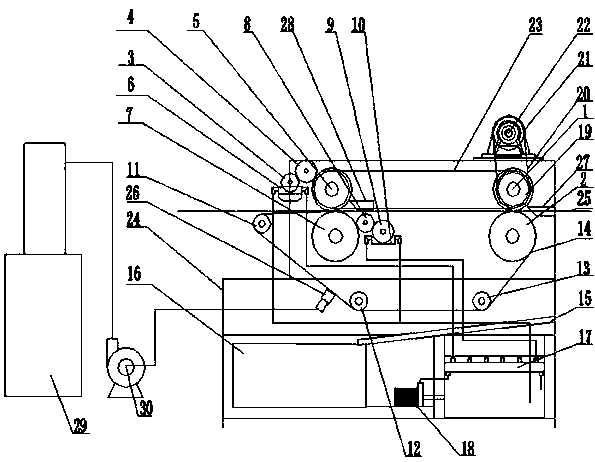

Textile fabric printing and dyeing device

InactiveCN104608482AUniform colorImprove printing and dyeing speedRotary pressesEngineeringMechanical engineering

The invention discloses a textile fabric printing and dyeing device which comprises a frame. Fixing blocks are arranged at the two ends of the frame. A printing and dyeing base plate is arranged between the fixing blocks at the two ends. A partition plate is arranged between the printing and dyeing base plate and the frame. A fabric adsorption device is arranged between the partition plate and the printing and dyeing base plate. The printing and dyeing base plate is provided with a scraper plate which can move in a reciprocating mode. An installation frame is further arranged on the frame, and a drive device is arranged on the installation frame and connected with a drive screw rod. The drive screw rod is connected with at least two atomization devices. Each atomization device is connected with a dye channel which is connected with the scraper plate. The frame is further provided with a dye recovery box. The inlet of the dye recovery box is flush with the tail end of the printing and dyeing base plate. The outlet of the dye recovery box is communicated with the atomization devices. The dye recovery box is further provided with a dye backflow drive device. The textile fabric printing and dyeing device can improve production efficiency, and is simple to operate and convenient to use.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

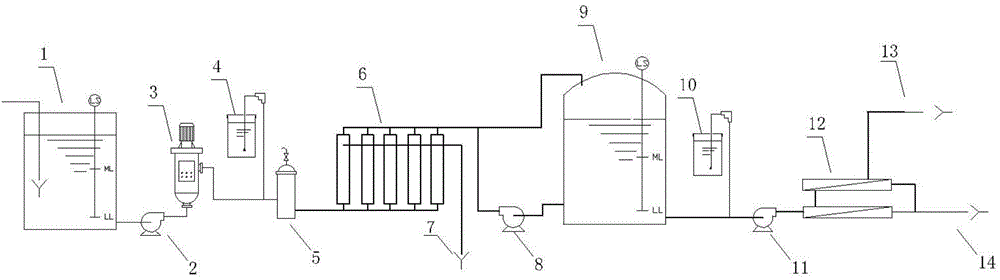

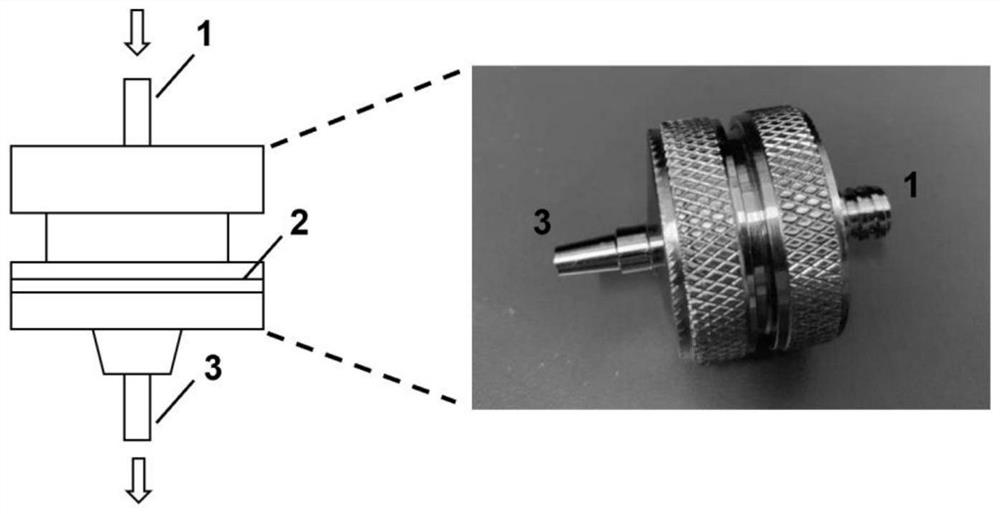

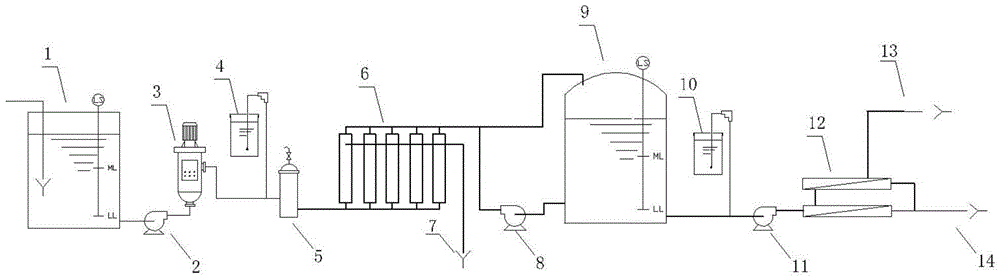

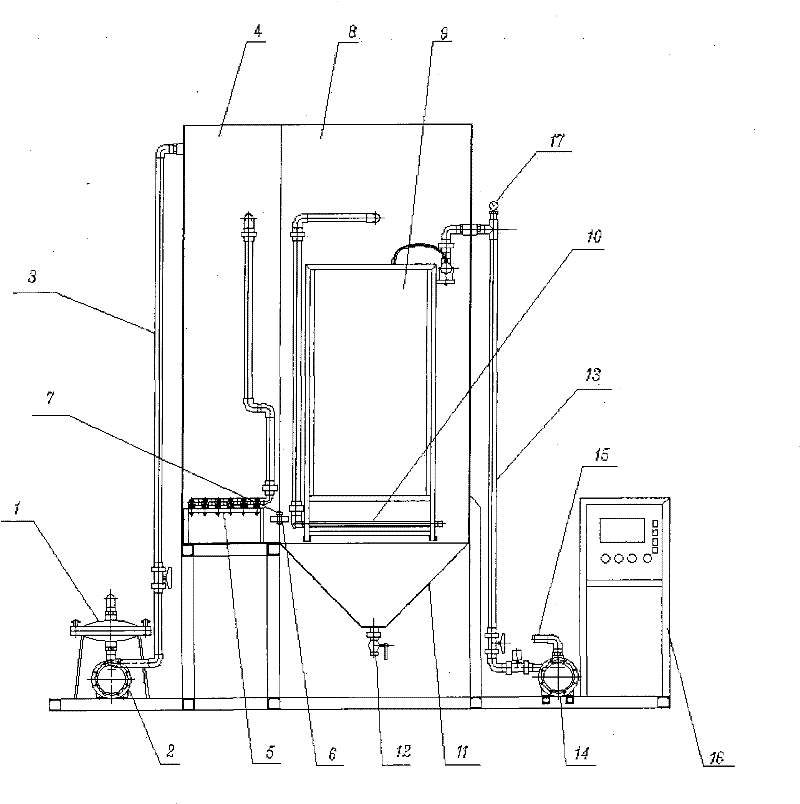

Device and method for realizing printing and dyeing dyed wastewater reuse and dye recovery

ActiveCN104609605AAchieve retentionAchieve reuseMultistage water/sewage treatmentSeparation technologyUltrafiltration

The invention relates to a printing and dyeing wastewater reuse, and particularly relates to a device and a method for printing and dyeing wastewater water-soluble dye recovery on the basis of a membrane separation technology. The device comprises a raw water booster pump, a self-cleaning filter, a precise filter, an ultrafiltration membrane assembly, an ultrafiltration backwash pump, an ultrafiltration water tank, a high-pressure pump, a nanofiltration membrane assembly, and a reducer and scale inhibitor pouring system which are communicated with a wastewater collection pool. The method comprises the steps of draining the dyed wastewater to the wastewater collection pool and pumping the dyed wastewater in the self-cleaning filter through the raw water booster pump to remove large-particle suspended matters and impurities, then entering the wastewater into the precise filter to remove the remainder suspended matters, then entering the wastewater into an ultrafiltration membrane to remove bacteria, colloids and macromolecular organic compounds, finally pumping the wastewater in a nanofiltration membrane device through the high-pressure pump to remove micromolecular organic compounds and divalent ions, thereby producing high-quality reclaimed water and simultaneously intercepting and recovering most of activated dye molecules.

Owner:DALIAN UNIV OF TECH

Printing device with dye instant mixing function

InactiveCN107187195AAvoid endless wasteUniform treatmentPrinting press partsEngineeringCirculating pump

The invention discloses a dye instant mixing printing device, which comprises a frame, a printing roller one, a printing roller two, a pressing roller, a dye storage tank one, a dye storage tank two, a dye mixing tank, a dye collecting tank and a circulating pump. Printing roller 1 and printing roller 2 are arranged above the frame, printing roller 1 and printing roller 2 are arranged in parallel, printing roller 1 and printing roller 2 are provided with pressing rollers, dye storage tank 1 and dye storage tank 2 are arranged above the frame , the dye storage tank 1 and the dye storage tank 2 are connected to the dye mixing tank through the dye conveying pipe. The dye recovery pipe and circulation pump are connected to the dye mixing tank, and the bottom of the dye mixing tank is provided with rotatable dye nozzles corresponding to the printing roller 1 and the printing roller 2 up and down. The dye storage tank 1 and the dye storage tank 2 can be used to store different dyes respectively, and the two different dyes can be mixed in real time according to the needs, so as to avoid the waste of the dyes after mixing, which is energy-saving and environmentally friendly.

Owner:TAICANG XINHE PRINTING & PACKAGING

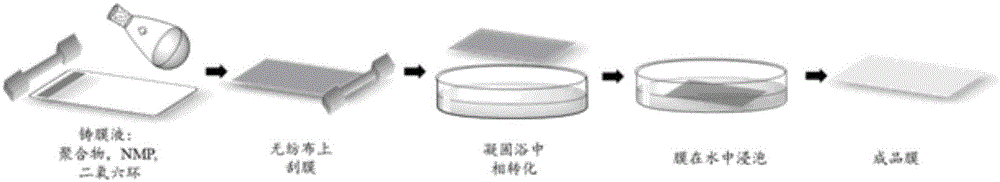

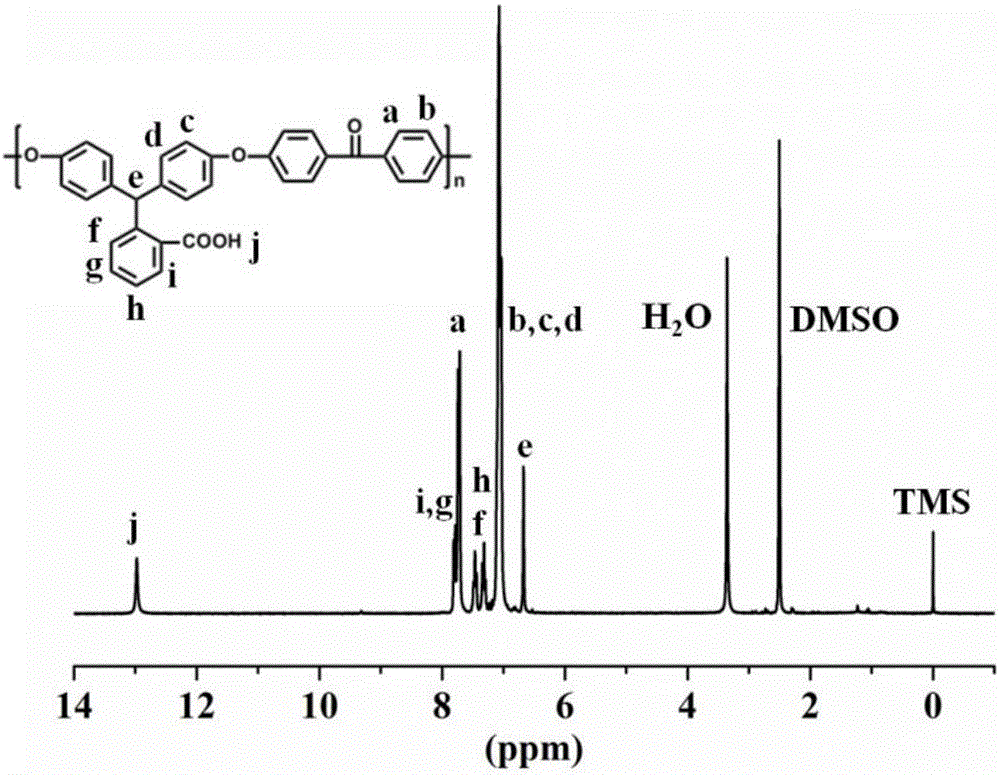

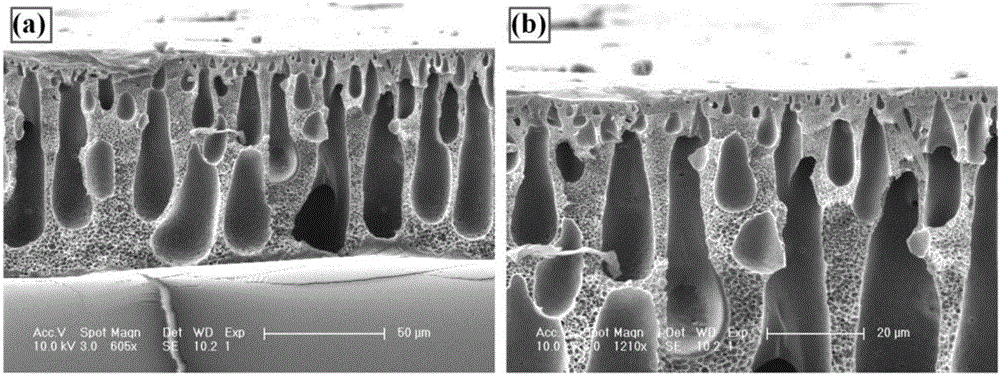

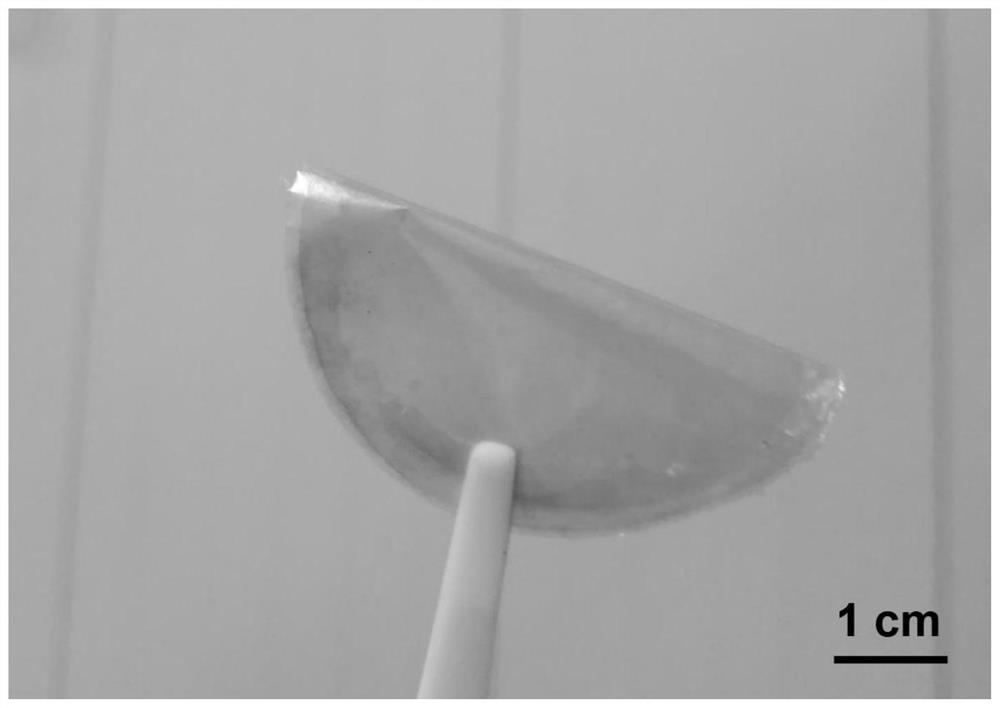

Nanofiltration membrane, and preparation method and application thereof

ActiveCN106693706AHas + temperature resistanceImprove hydrophilicityWater contaminantsReverse osmosisStainingSide chain

The invention provides a preparation method of a nanofiltration membrane. The method comprises the following steps: A) mixing a polymer with a solvent and a cosolvent to obtain a polymer solution; and B) pouring the polymer solution to a support surface, scraping the membrane, and carrying out phase inversion on the primary membrane in a coagulation bath water solution, wherein the polymer is prepared by carrying out reaction on organic halide and phenolphthalin, and the organic halide is selected from one or both of dichlorodiphenylsulfone and difluorodiphenylketone, or tetrafluorodiphenylsulfone. The polyether sulfone or polyaryletherketone containing carboxyl in the side chain is used as the raw material to prepare the novel hydrophilic nanofiltration membrane by the non-solvent-induced phase inversion process. The nanofiltration membrane can be used for dye-containing wastewater decolorization, dye recovery and purification and other water treatment processes. The result indicates that the nanofiltration membrane has higher separation efficiency and staining resistance for negatively charged dyes dissolved in the water body.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for synchronously removing and stepwise recovering sulfoacid dye and heavy metal ion through resin

InactiveCN102976446AReduce pollution concentrationLow costWater contaminantsWater/sewage treatment by ion-exchangePhysical chemistryDye recovery

The invention discloses a method for synchronously removing and stepwise recovering sulfoacid dye and heavy metal ion through resin, and belongs to the field of resourceful treatment of dye-heavy-metal composite wastewater. The method comprises the following steps: (1) synchronous absorbing: adjusting the pH (Potential of Hydrogen) of the composite wastewater containing sulfoacid dye and heavy metal ion to 3 to 6, and then pumping the composite wastewater into an adsorption column filled by absorption resin; (2) recovery of heavy ion: desorbing the absorption resin through common inorganic acid desorption solvent at the first time after accomplishing step (1), and stopping the first desorption after no heavy ion is inspected in the output water; and (3) recovery of dye: desorbing the absorption resin through common inorganic alkali desorption solvent at the second time after accomplishing step (2), wherein the completely reproduced resin can be recycled after being washed to reach neutral by clean water. By adopting the method, the pollution concentration of the sulfoacid dye and heavy metal ion can be greatly reduced, and high-purity sulfoacid dye and high-purity heavy metal ion can be stepwise recovered and can be applied to resource reclamation.

Owner:NANJING UNIV

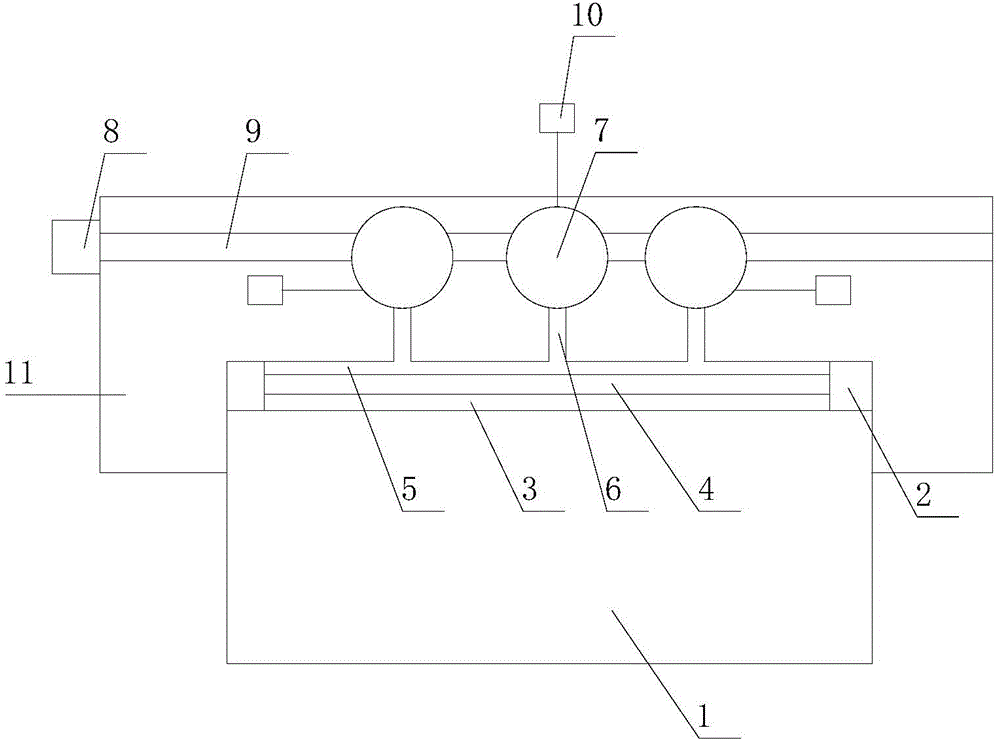

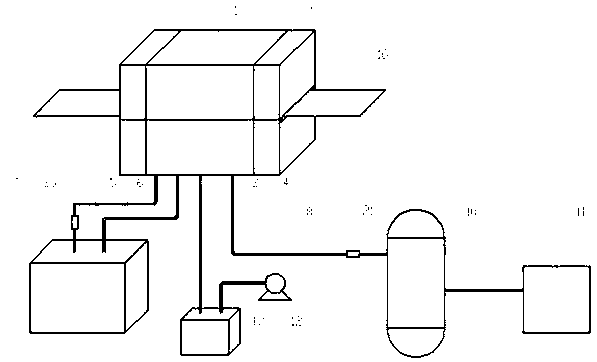

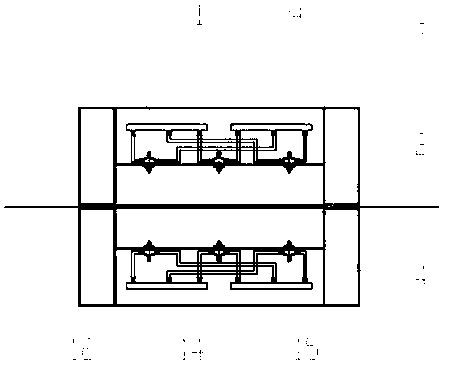

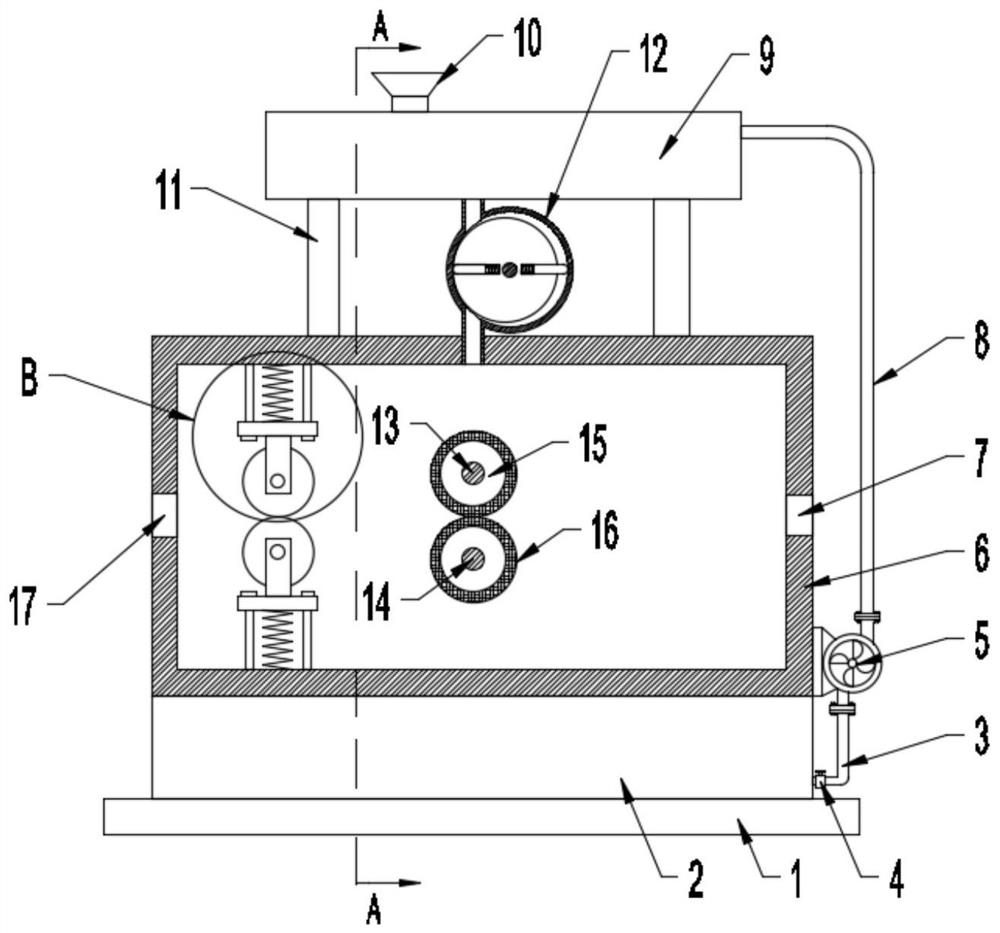

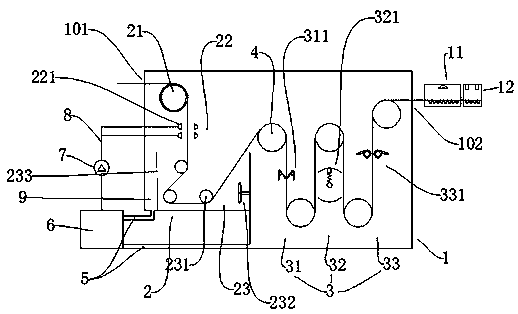

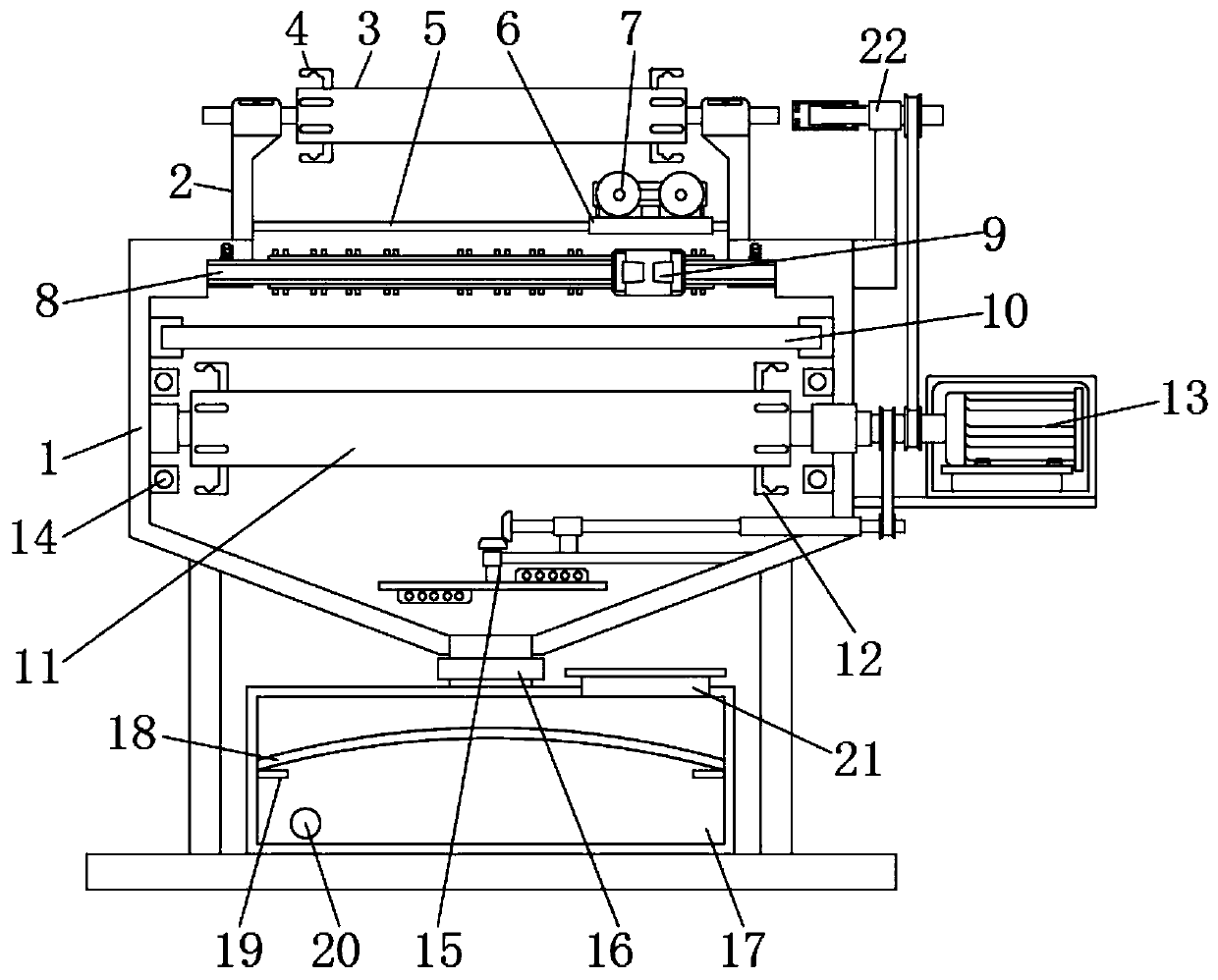

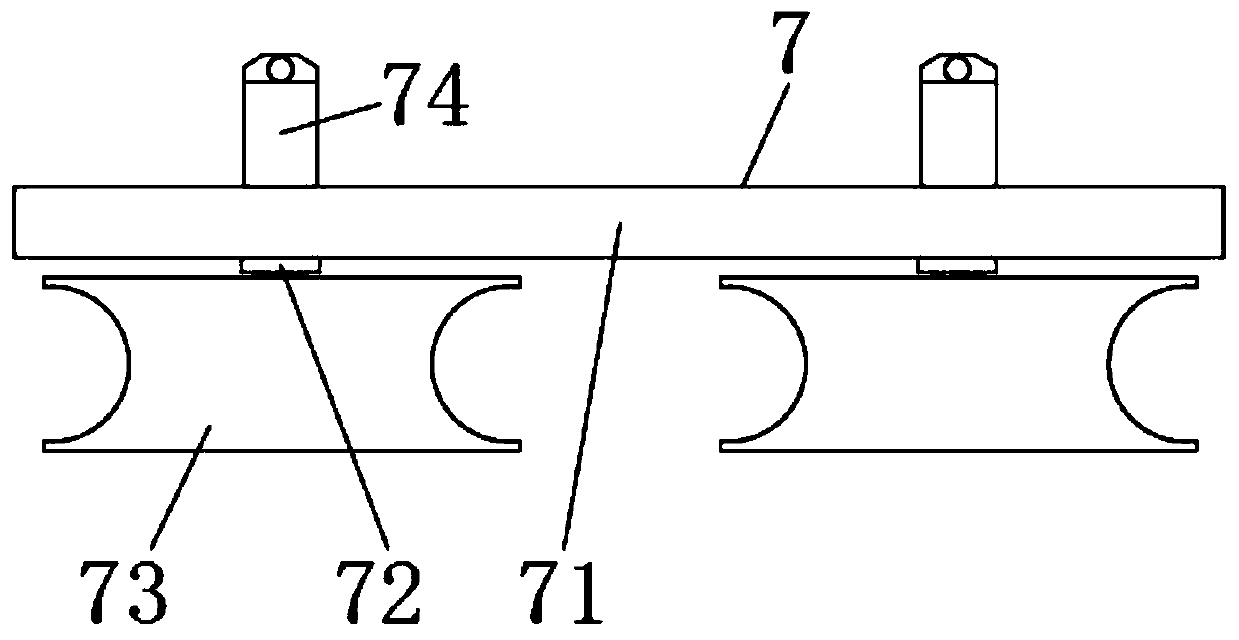

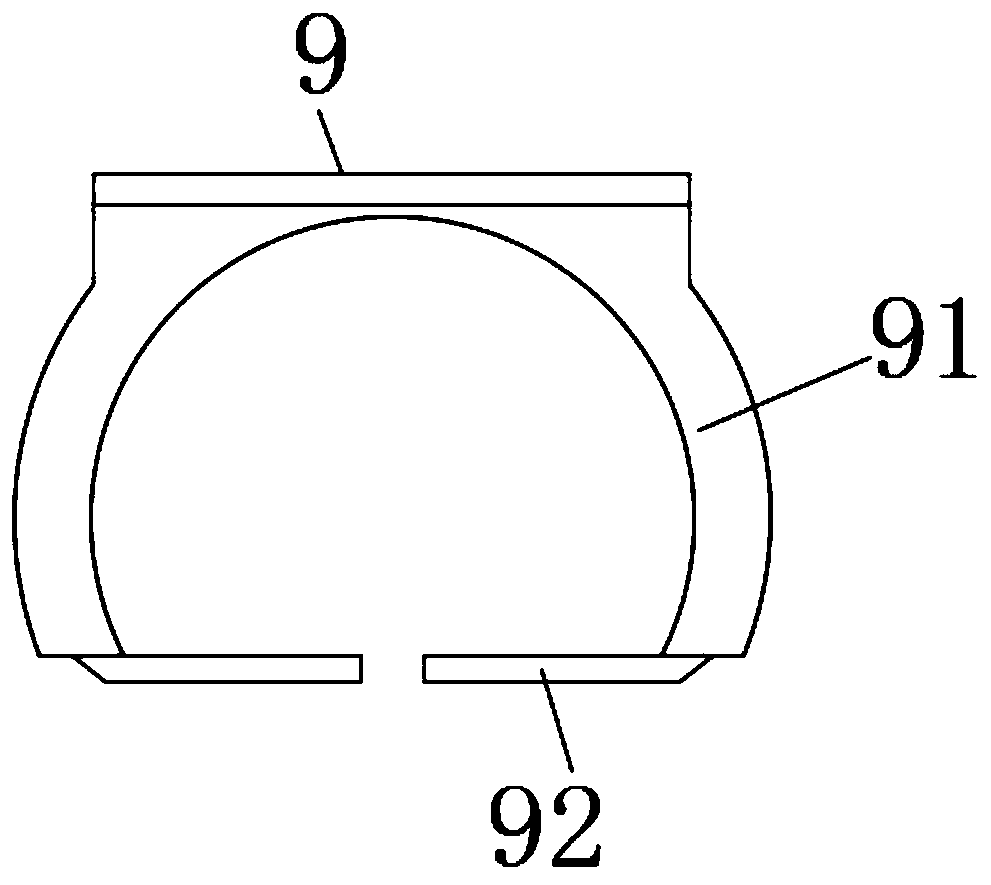

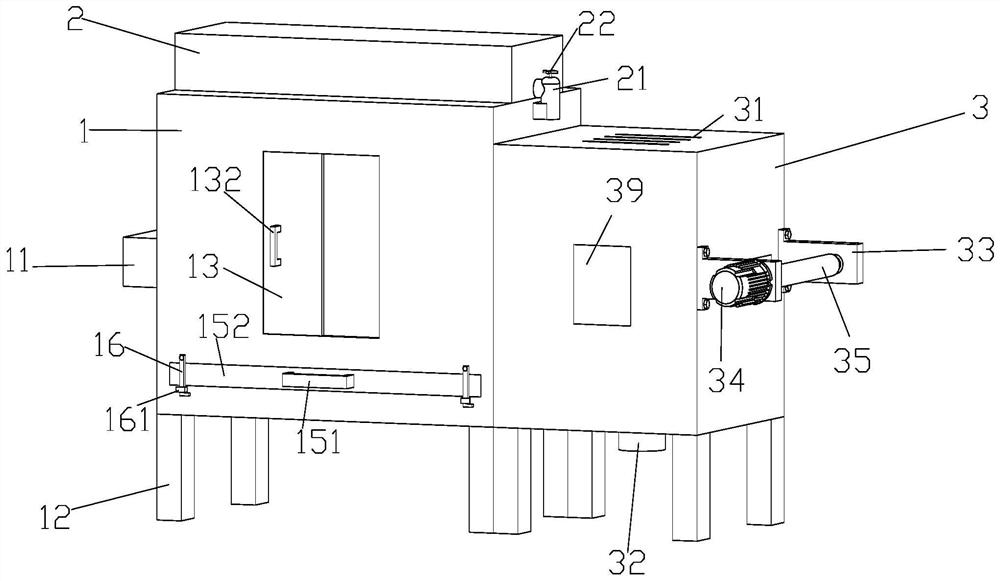

Intelligent horizontal spray-dyeing device and use method thereof

PendingCN108842332AReduce CODReduce chromaCoatings with pigmentsTextile treatment machine arrangementsWater useFiber

The invention discloses an intelligent horizontal spray-dyeing device and a use method thereof. The intelligent horizontal spray-dyeing device is used for uniform paper or cloth coloring and comprisesupper and lower spray-dyeing box bodies (1 and 2), upper and lower negative-pressure air-liquid recovery box bodies (3 and 4), a dye supply pipeline (5), a dye recovery pipeline (6), a dye tank (7),a compressed air supply pipeline (8), a spray nozzle (9), an air storage tank (10), an air compressor (11), a negative-pressure vacuum pump (12), an air-liquid separator (13), an air distributing device (14) and a liquid distributing device (15). By applying the intelligent horizontal spray-dyeing device, dyes can be decreased by 40% when colorful paper or fiber textile products are printed and dyed, the water use amount can be decreased by 30%, the COD, BOD and chrominance of printing and dyeing wastewater are greatly reduced, the sewage treatment cost is reduced by 70%, the reuse times of the printing and dyeing wastewater are increased, and the purposes of saving energy, reducing emissions and saving water resources are achieved.

Owner:株洲麒麟科技有限公司

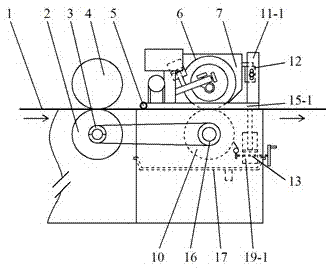

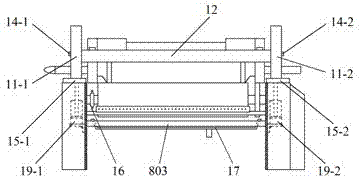

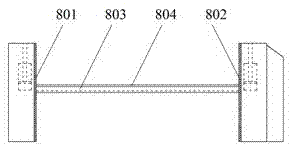

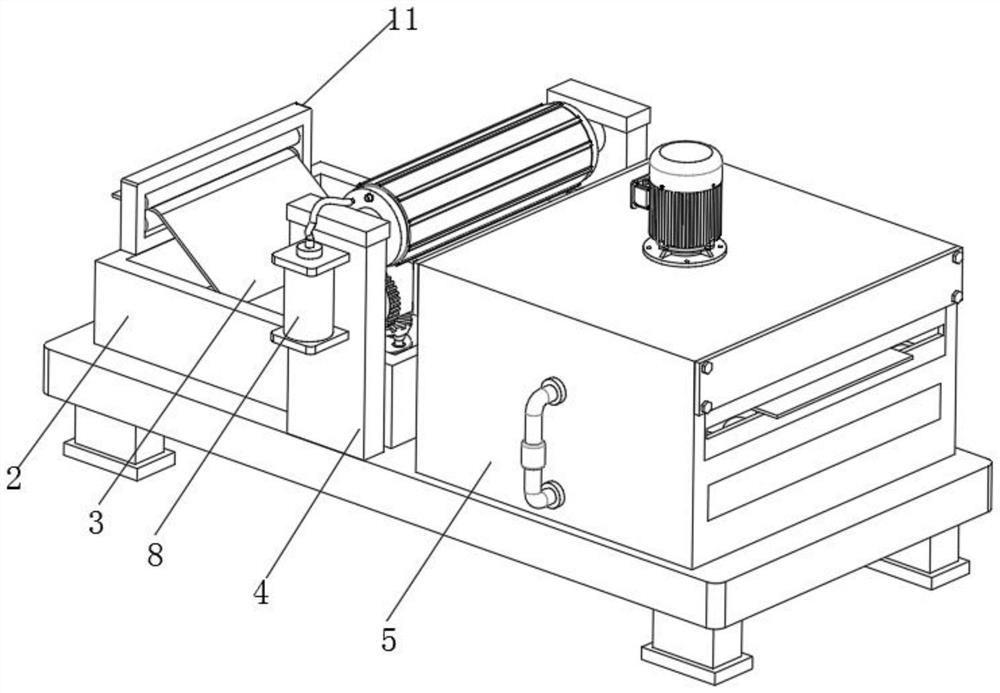

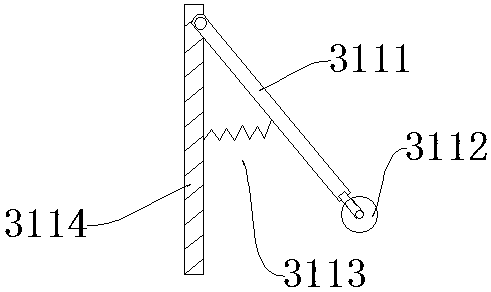

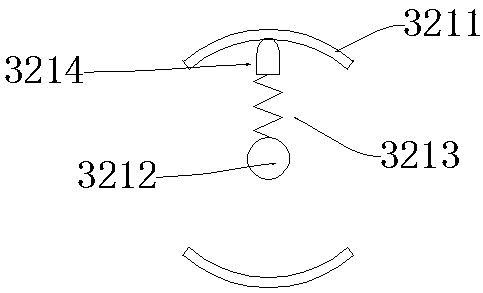

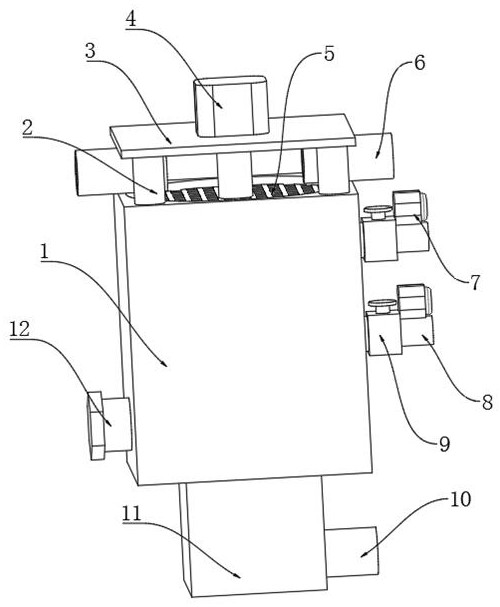

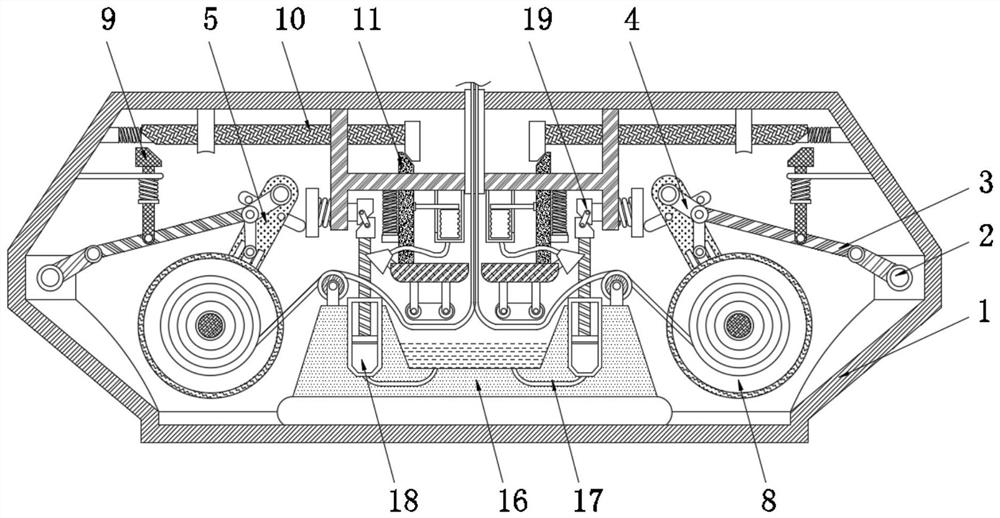

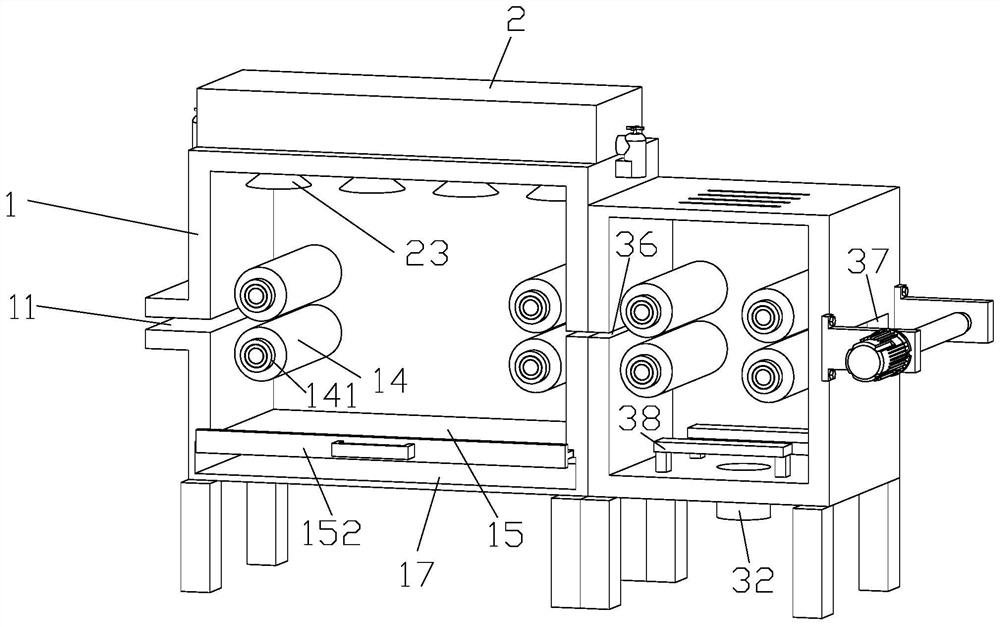

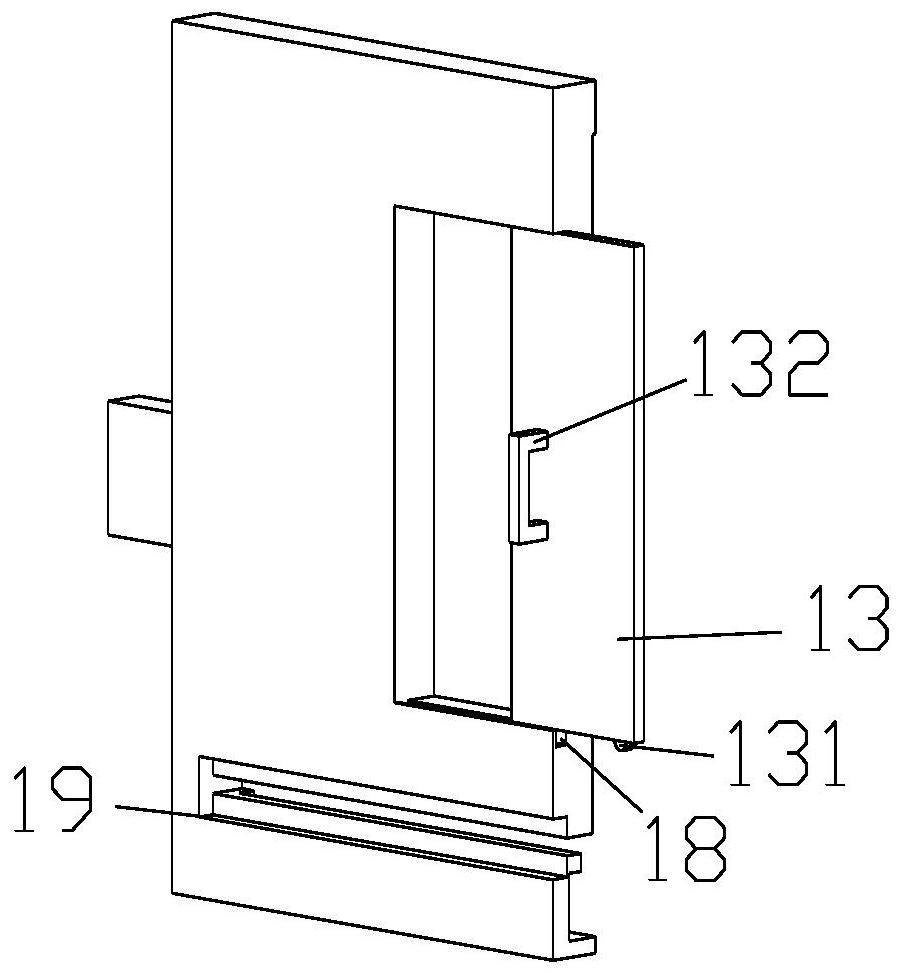

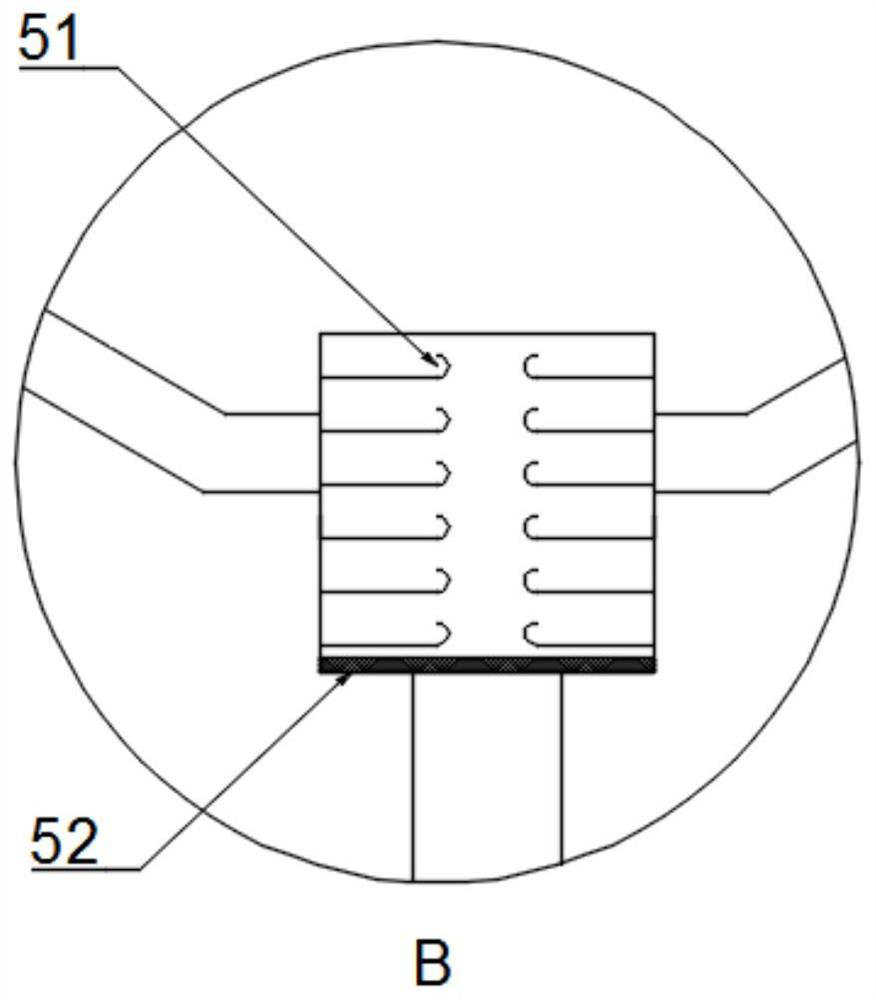

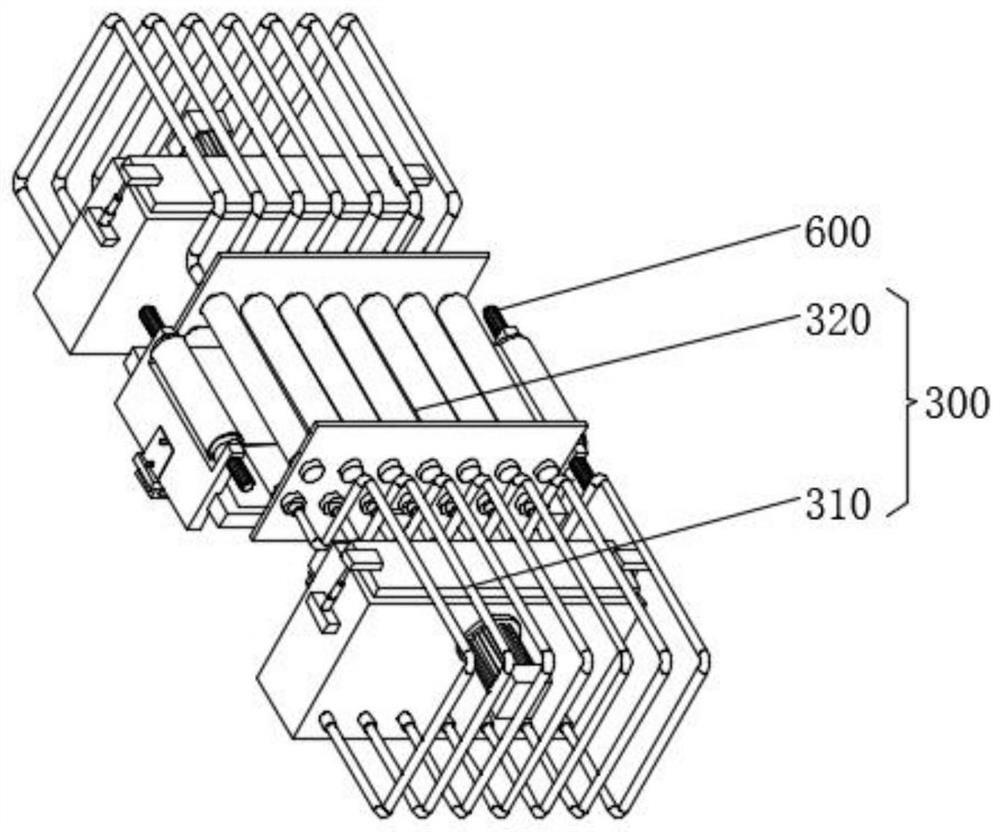

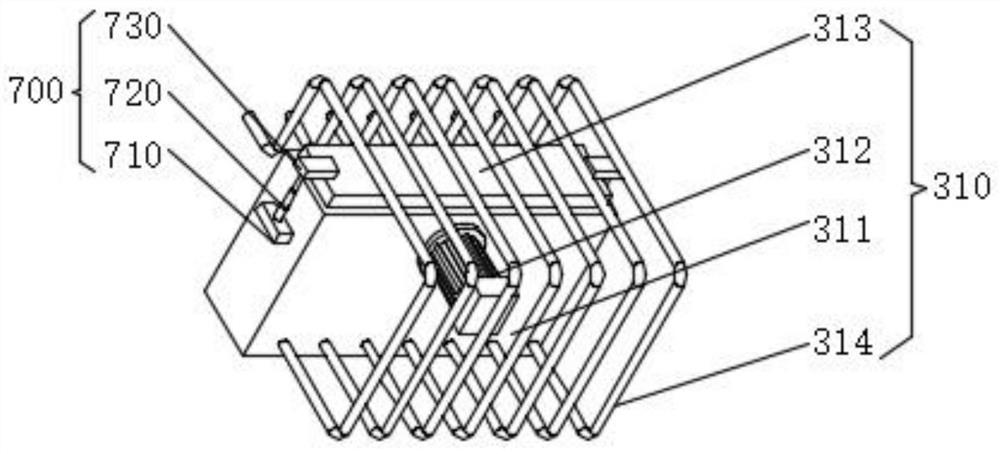

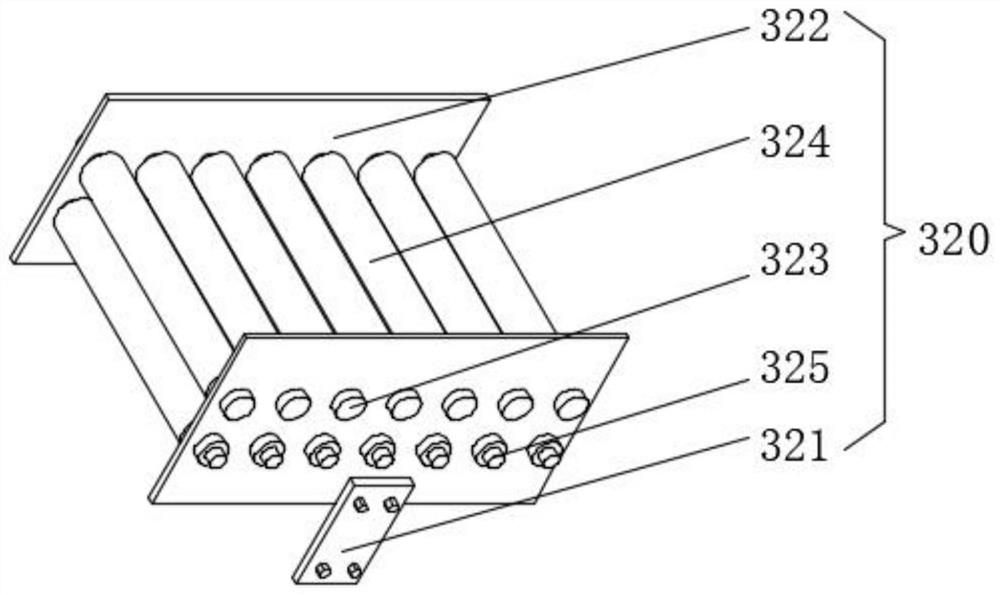

Warp printing module oriented to sizing machine

InactiveCN106956499ADoes not affect normal useEasy to installScreen printersLiquid/gas/vapor textile treatmentComputer moduleEngineering

The invention provides a warp printing module oriented to a sizing machine. The warp printing module can be rapidly installed between a sizing machine slurry groove and a drying chamber, and synchronous production of sizing and warp printing can be achieved. The warp printing module comprises a rack, a printing assembly, a supporting roller, two movable bases, two lifting air cylinders, a drive chain wheel, a driven chain wheel, a cleaning device and a dye recovery groove. The printing assembly is installed on the left movable base and the right movable base. The two movable bases are arranged above the left side and the right side of the rack correspondingly. Each movable base is connected with the rack through a hinge at the rear end, and the front end of each movable base is connected with an acting arm of one lifting air cylinder. The supporting roller is located under a printing round net. The driven chain wheel is fixedly arranged on one side of a supporting roller shaft, and the drive chain wheel is installed on the corresponding side of a sizing roller shaft of the sizing machine, is of a Haff-shaped structure and is provided with two fastening screws. The cleaning device is arranged below the front side of the supporting roller.

Owner:YANCHENG INST OF IND TECH

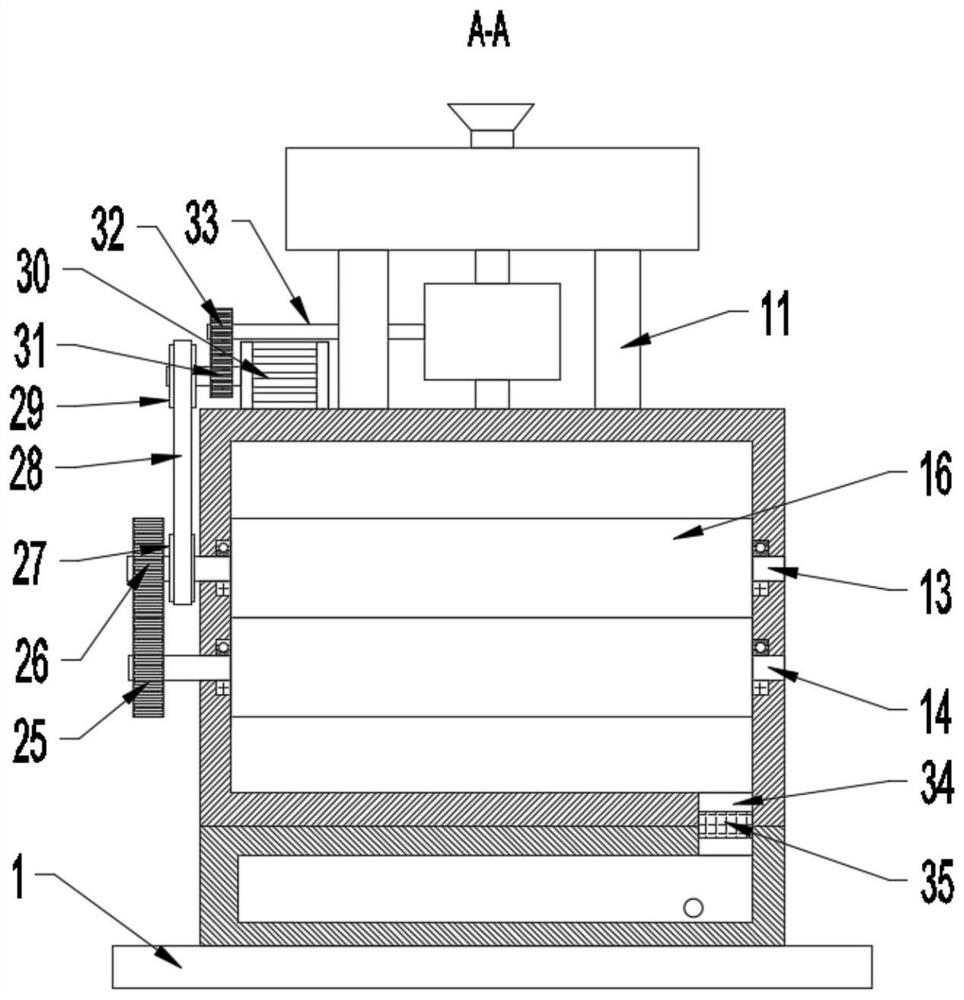

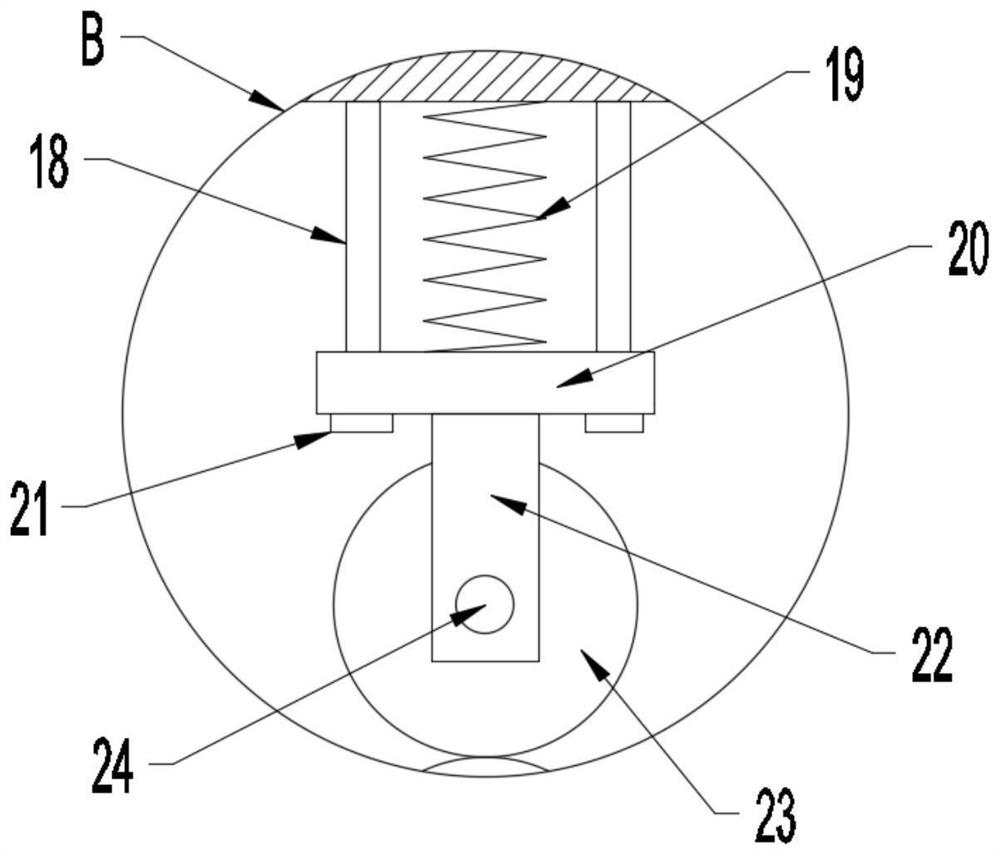

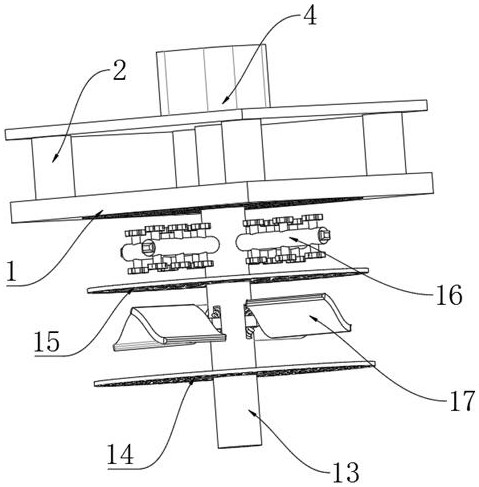

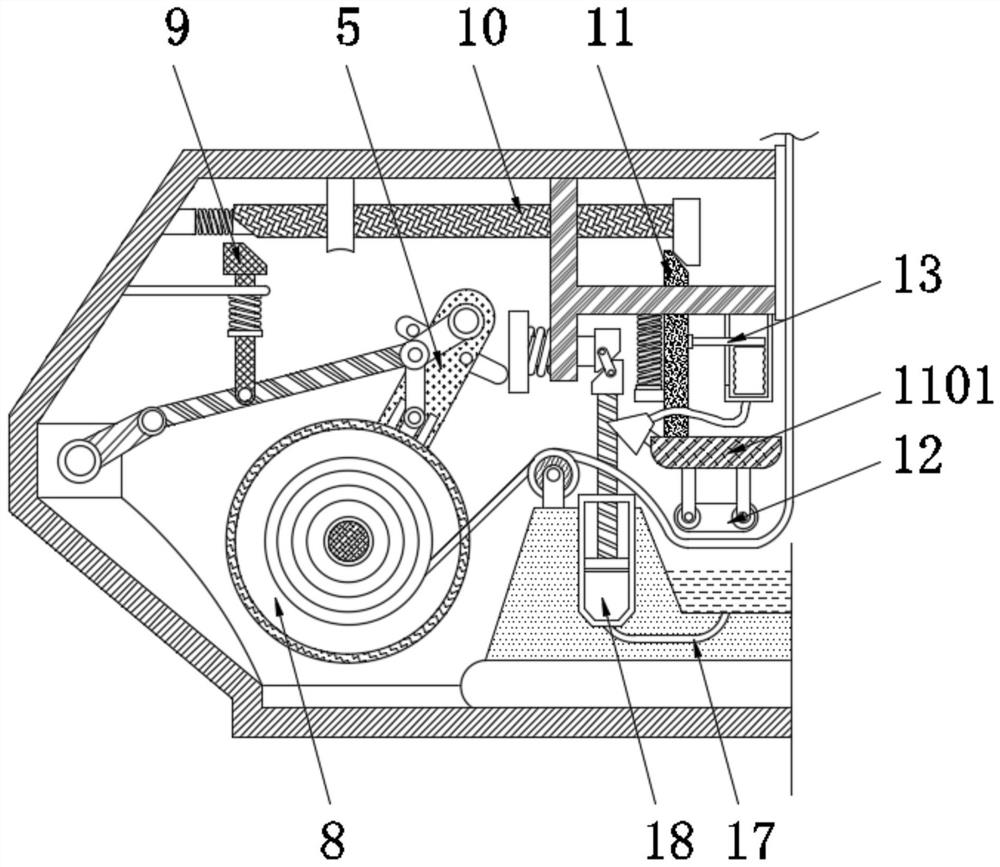

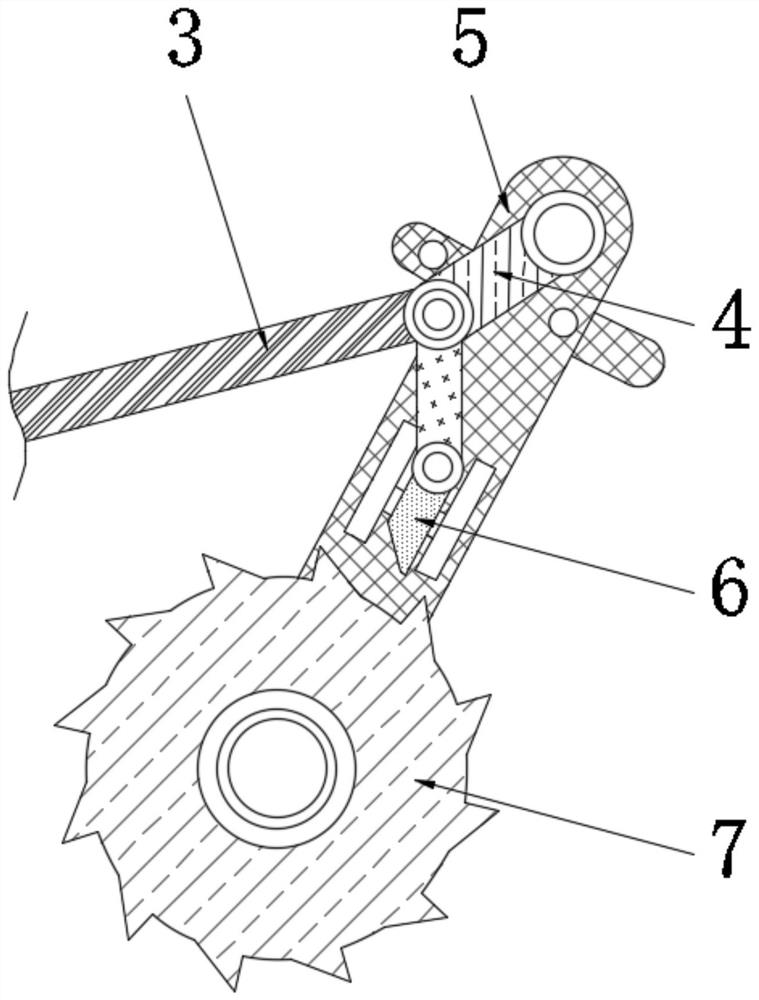

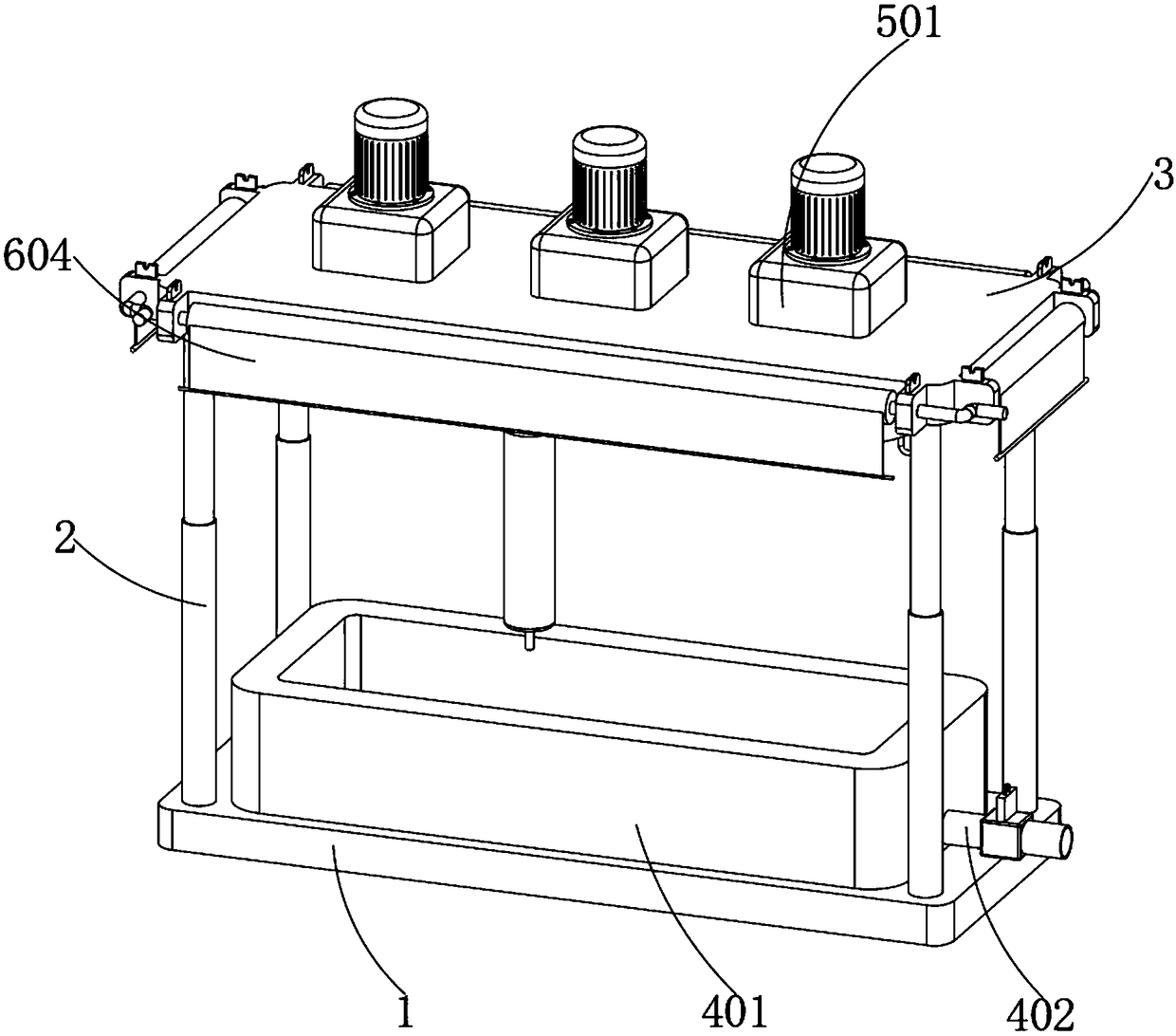

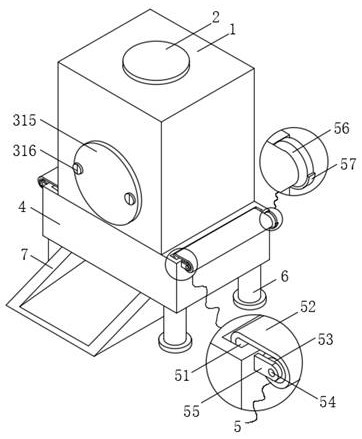

Textile fabric dyeing equipment for spinning

PendingCN113529306AAdd evenlyLow costTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentProcess engineeringDye recovery

The invention is applicable to the technical field of dyeing, and provides textile fabric dyeing equipment for spinning. The textile fabric dyeing equipment comprises a dyeing box and a dye supply box, and further comprises a textile fabric dyeing mechanism; the textile fabric dyeing mechanism is mounted on the dyeing box, and the textile fabric dyeing mechanism comprises a dyeing assembly, a feeding assembly, a driving assembly, a pipeline assembly and a dye recovery assembly; the feeding assembly is driven by the driving assembly to evenly add dye in the dye supply box to the dyeing assembly; and the dyeing assembly is driven by the driving assembly to dye textile fabric. The textile fabric is fed into the dyeing box, the feeding assembly is driven by the driving assembly to evenly add dye to the dyeing assembly through the pipeline assembly, it is guaranteed that the dye is evenly and continuously added to the dyeing assembly, the driving assembly drives the dyeing assembly to dye the textile fabric, and then the dye recycling assembly recycles redundant dye in the dyeing box, so that the cost is saved.

Owner:林翰绵

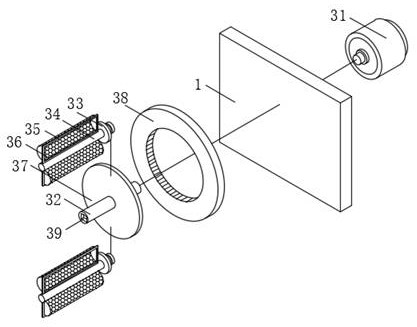

Sectional type printing and dyeing system and printing and dyeing method for improving dyeing degree of cloth

PendingCN114592294AAvoid wastingPlay the role of recycling dyeDispersed particle separationLiquid/gas/vapor removal by squeezing rollersAir pumpProcess engineering

The invention discloses a sectional type printing and dyeing system capable of improving the dyeing degree of cloth and a printing and dyeing method, and relates to the field of textile processing. The sectional type printing and dyeing system comprises a base, a dye vat and a cloth body, and an adjusting assembly can connect the inflation output end of an air pump with an air inlet nozzle according to the thickness of the cloth; therefore, the adjusting assembly can be adjusted according to the thicknesses of different cloths, the dye recovery device can adapt to dye recovery work of various cloths, residual water vapor in hot air is adsorbed after passing through absorbent cotton, air in the drying cavity enters the drying cavity through a flow guide pipe to be heated and utilized again, and the recovery efficiency is improved. Excessive dye left in the cloth body is squeezed out by the adjusting assembly and the matching roller, the effect of recovering the dye is achieved, waste of the dye is avoided, gas in the cavity of the movable hole is squeezed out from the exhaust nozzle and released in the dye vat through the exhaust port, dye solids deposited at the bottom of the dye vat are blown away by floating bubbles, and the stirring effect is achieved.

Owner:杭州航民美时达印染有限公司

Cloth dyeing machine

PendingCN109763285AFully uniform printing and dyeingImprove printing and dyeing effectMechanical cleaningPressure cleaningPulp and paper industryDye recovery

The invention relates to the field of cloth printing and dyeing, in particular to a cloth dyeing machine. The cloth dyeing machine comprises a cloth dyeing box, wherein the cloth dyeing box comprisesa printing and dyeing area with a cloth inlet and a functional area with a cloth outlet; an unwinding roller located at the cloth inlet, a spray structure located below the unwinding roller and a printing and dyeing tank arranged below the spray structure are arranged in the printing and dyeing area; the functional area comprises an extrusion section, a flicking section and a scraping section which are sequentially formed under guide of multiple vertically alternate drive rollers; the printing and dyeing area and the functional area are both connected with a dye tank arranged outside the clothdyeing box through dye recovery pipelines; the dye tank is connected with the spray structure through a power pump and a dye delivery pipeline. The cloth dyeing machine can dye cloth fully and uniformly and scrape extra dye and attached impurities on the surface of cloth.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

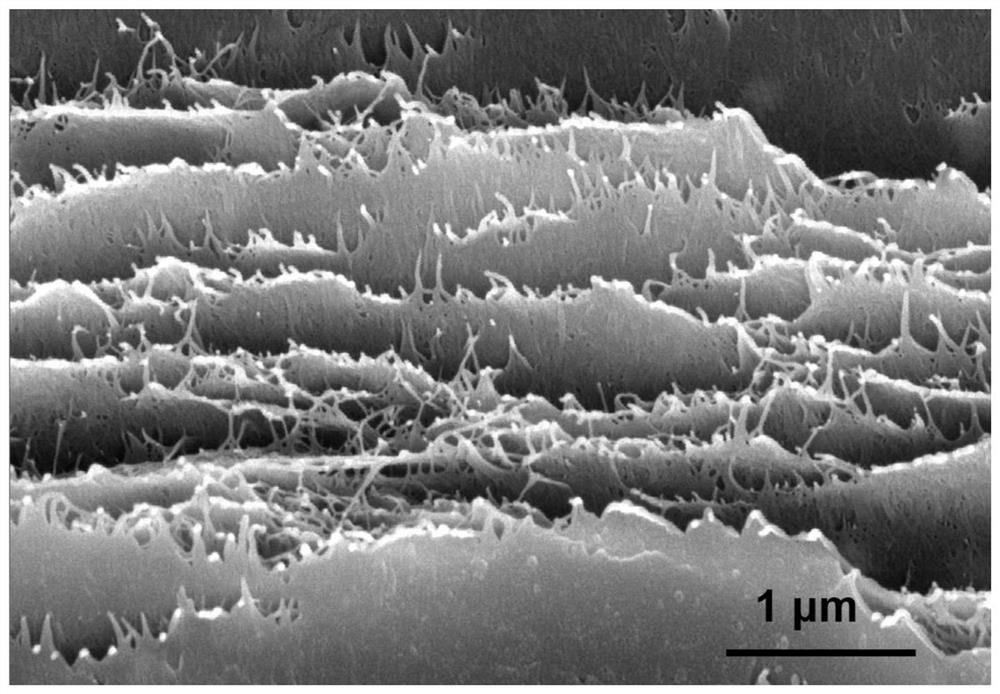

Aramid loose nanofiltration membrane as well as preparation method and application thereof

ActiveCN112588123AImprove hydrophilicityHigh mechanical strengthMembranesSemi-permeable membranesYarnCongo red

The invention provides an aramid loose nanofiltration membrane for efficient dye-salt separation as well as a preparation method and application thereof. The method comprises the following steps: crushing para-aramid fiber yarns, then carrying out alkali treatment, dropwise adding an obtained aramid nanofiber spinning solution into a phosphoric acid solution, performing standing, stirring and ultrasonic treatment, and carrying out ice-bath ultrasonic treatment on the obtained hydrophilic aramid nanofiber sol and Ti3C2Tx two-dimensional nanosheets under an alkaline condition to obtain the aramid loose nanofiltration membrane. The preparation of the membrane is based on the spatial characteristic of three-dimensional interconnection of an aramid fiber skeleton, so that the membrane has the characteristic of high porosity, and further has the separation characteristic and good self-cleaning capability of a nanofiltration membrane. The membrane is used for efficiently recovering dyes afterdye-salt separation, realizes efficient separation and interception of dyes such as Congo red, rose-bengal and alcian blue by utilizing the screening performance of the aramid fiber skeleton after rigid two-dimensional nanosheet intercalation and a reconstructed nano water channel under low pressure, and is suitable for rapid treatment and dye recovery of high-salt printing and dyeing wastewater.

Owner:TONGJI UNIV

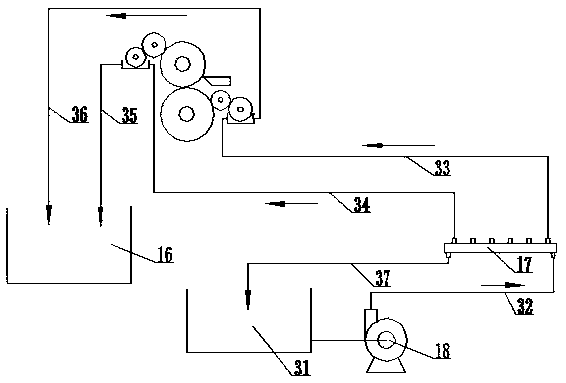

Colored paper making and coloring equipment and method

PendingCN110965392ALow costReduce processing costsPaper/cardboardPulp material addition processesPapermakingSewage

The invention discloses colored paper making and coloring equipment and method. The equipment comprises a rack, a water squeezing main rotating smooth roller, a water squeezing rubber roller, an uppercoloring smooth roller, an upper coloring rubber roller, an upper coloring rotating smooth roller, an upper dye tank, a lower coloring rotating rubber roller, a lower coloring smooth roller, a lowercoloring rubber roller, a lower dye tank, a tensioning roller, a transmission blanket, a power device, a dye recovery tank, a dye recovery storage tank, a dye conveying pump and a dye storage tank. The invention further comprises a coloring method. By utilizing the equipment and method, the coloring dye cost is reduced by 40%, the colored paper papermaking sewage treatment cost is reduced by 70%,most of papermaking sewage can be recycled, water resources are saved, in addition, the coloring uniformity effect is better, the application range is wider, and more colored paper with different colors and product quality requirements can be produced.

Owner:株洲麒麟科技有限公司

A device and method for realizing reuse of printing and dyeing wastewater and recovery of dyestuffs

ActiveCN104609605BAchieve retentionAchieve reuseMultistage water/sewage treatmentSeparation technologyHigh pressure

The invention relates to a printing and dyeing wastewater reuse, and particularly relates to a device and a method for printing and dyeing wastewater water-soluble dye recovery on the basis of a membrane separation technology. The device comprises a raw water booster pump, a self-cleaning filter, a precise filter, an ultrafiltration membrane assembly, an ultrafiltration backwash pump, an ultrafiltration water tank, a high-pressure pump, a nanofiltration membrane assembly, and a reducer and scale inhibitor pouring system which are communicated with a wastewater collection pool. The method comprises the steps of draining the dyed wastewater to the wastewater collection pool and pumping the dyed wastewater in the self-cleaning filter through the raw water booster pump to remove large-particle suspended matters and impurities, then entering the wastewater into the precise filter to remove the remainder suspended matters, then entering the wastewater into an ultrafiltration membrane to remove bacteria, colloids and macromolecular organic compounds, finally pumping the wastewater in a nanofiltration membrane device through the high-pressure pump to remove micromolecular organic compounds and divalent ions, thereby producing high-quality reclaimed water and simultaneously intercepting and recovering most of activated dye molecules.

Owner:DALIAN UNIV OF TECH

Textile dye recovery device

ActiveCN113336352ARecycling impactEasy to take outSpecific water treatment objectivesWater contaminantsMicrofiltration membraneUltrafiltration

The invention discloses a textile dye recovery device, and relates to the technical field of textile dye recovery. The problem that the textile dye recovery efficiency is low is solved. The device specifically comprises a filter box body, two waste liquid inlets are formed in the outer wall of the top end of the filtering box body; a circular inner cavity, a conical inner cavity and a circular through hole are formed in the filtering box body; the conical inner cavity is positioned below the circular inner cavity; the circular through hole is positioned below the conical inner cavity; the inner wall of one side of the circular inner cavity is fixedly connected with a filtering fence, an ultrafiltration membrane and a microfiltration membrane respectively; and the micro-filtration membrane is positioned below the filtration fence. By arranging the circular through hole, the electric push rod, the pushing plate, the ultrafiltration membrane, the microfiltration membrane and the filtering fence, the electric push rod is operated to push the pushing plate upwards, so that dialysate penetrates through the ultrafiltration membrane to move upwards, substances blocked in the ultrafiltration membrane are extruded out, the situation that dye recovery is affected by blockage of the ultrafiltration membrane is prevented, and the recycling efficiency of the device is improved.

Owner:南通原朴纺织科技有限公司

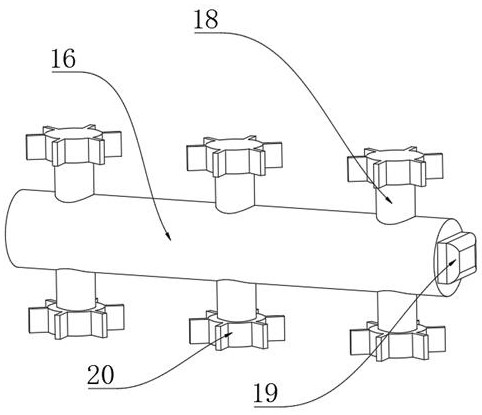

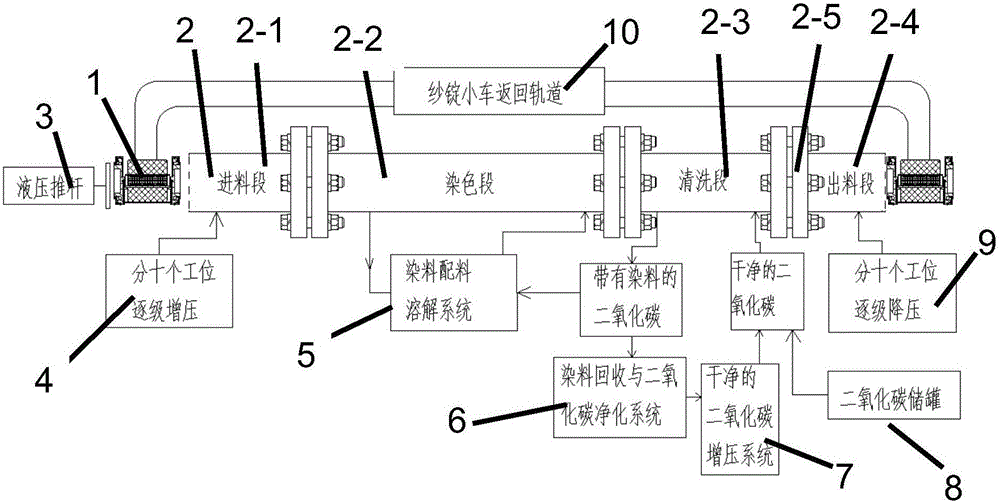

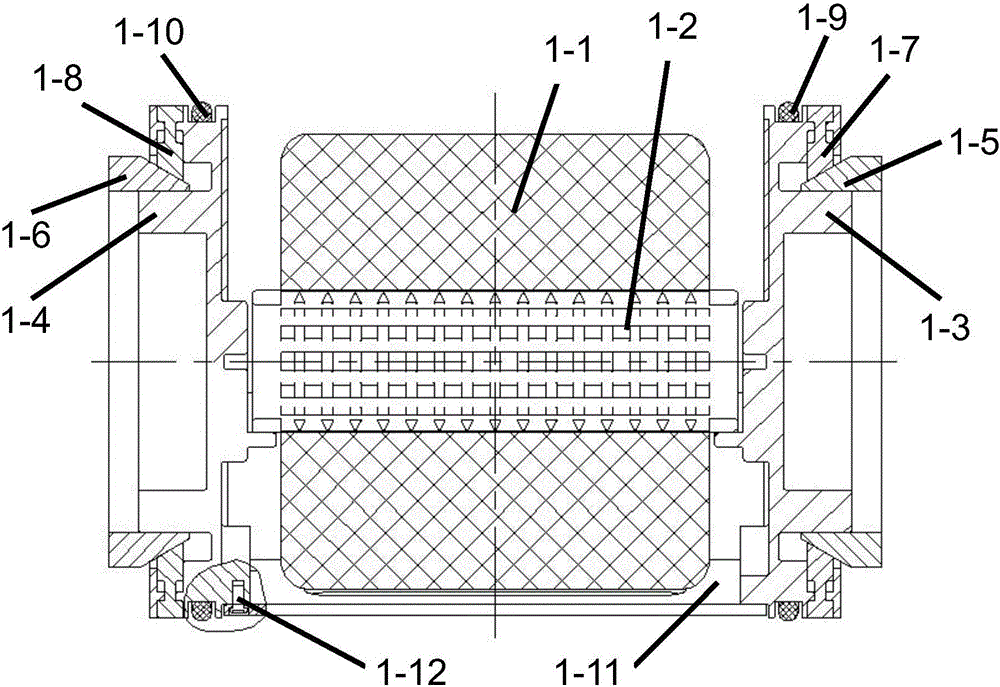

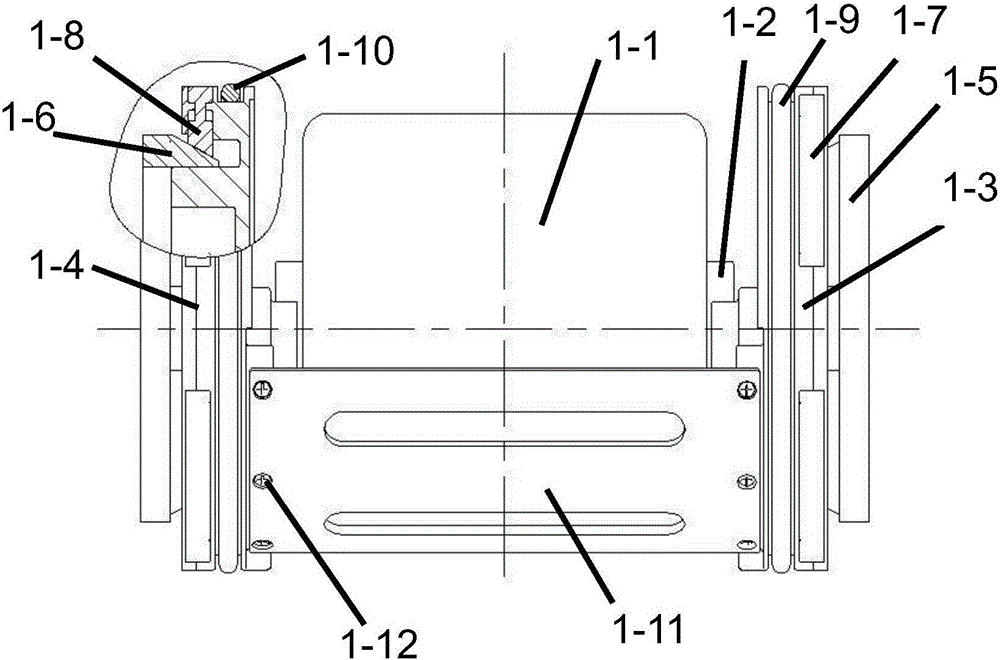

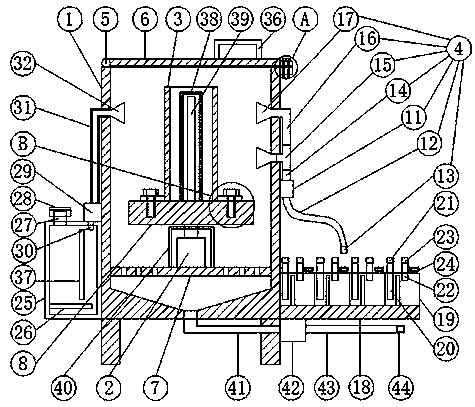

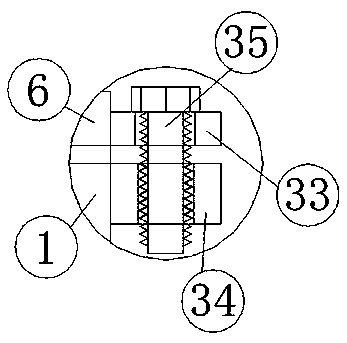

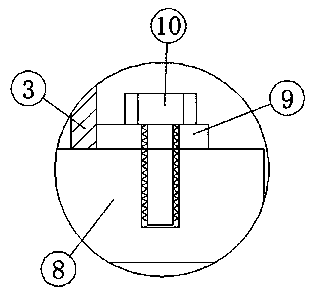

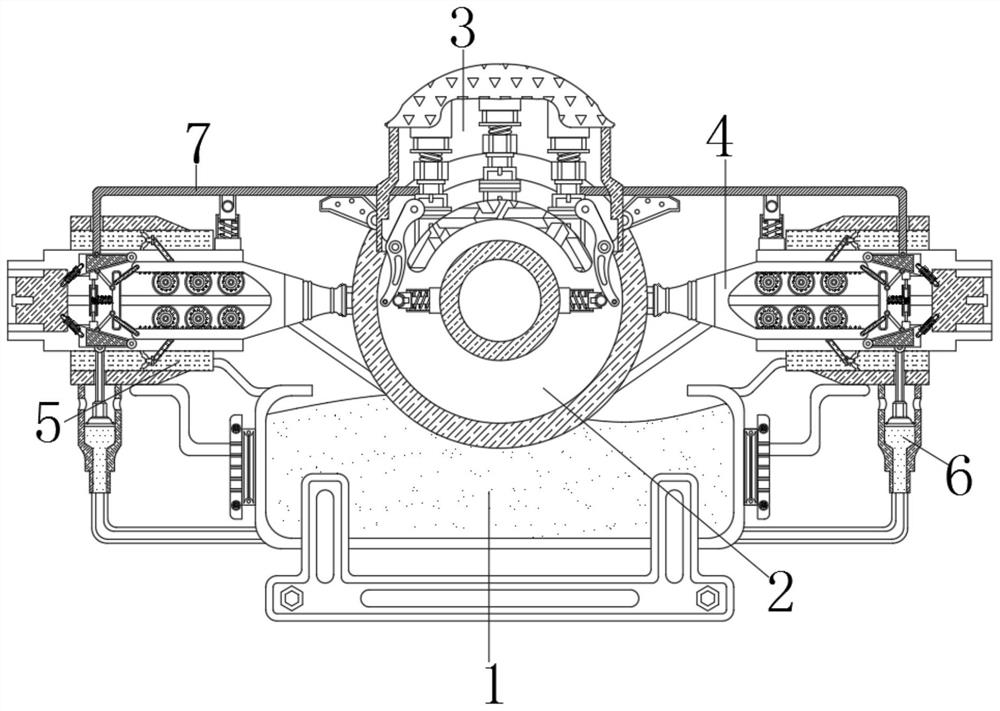

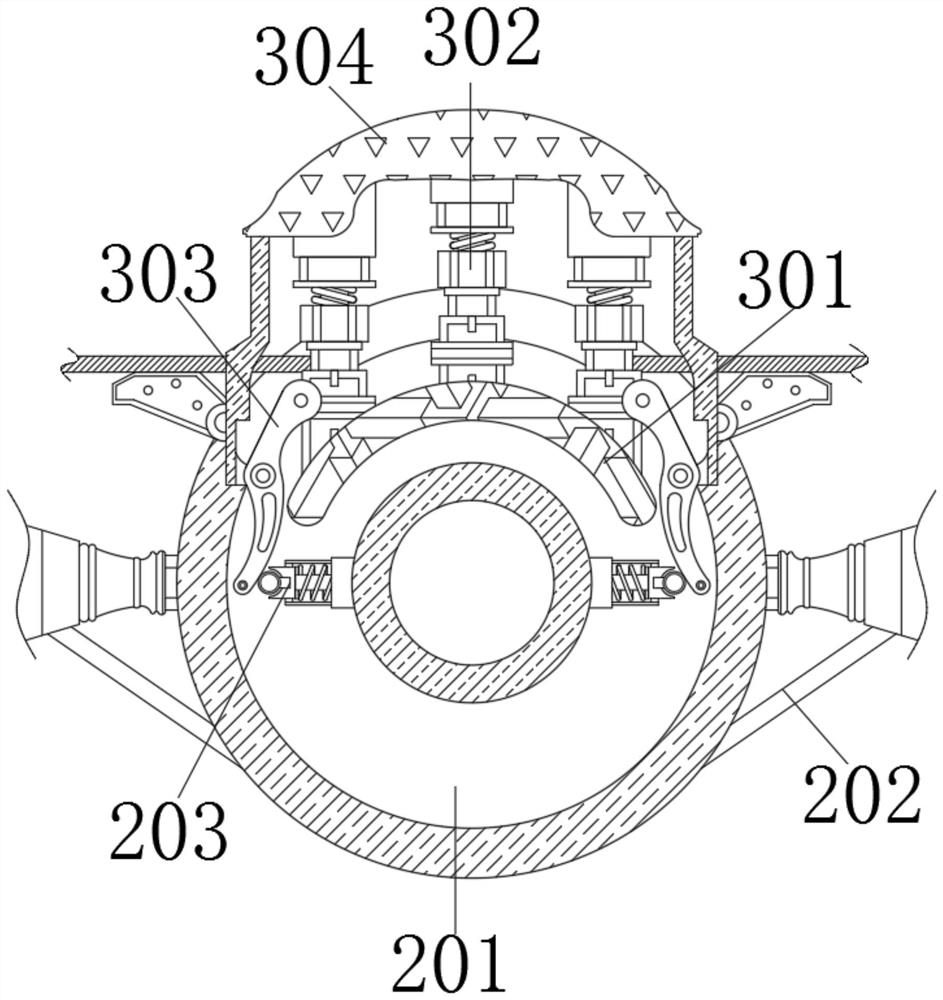

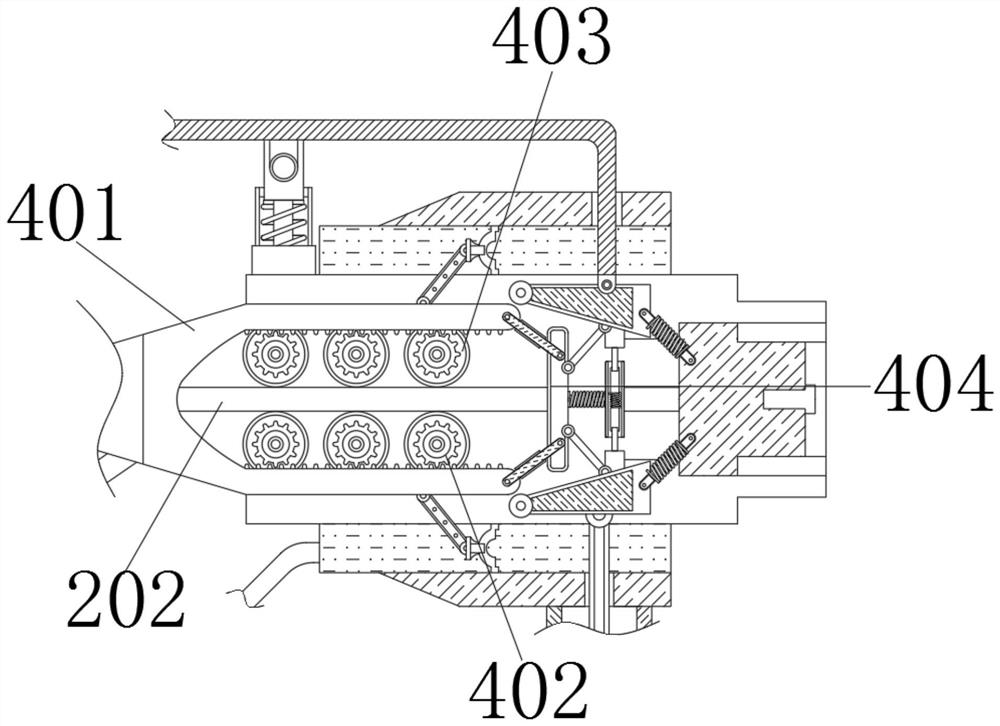

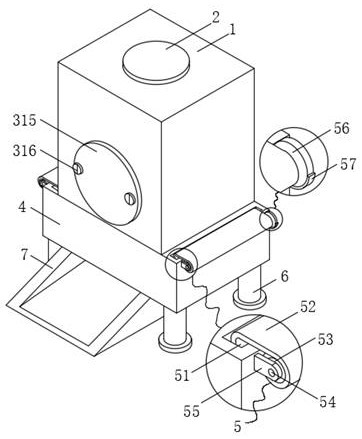

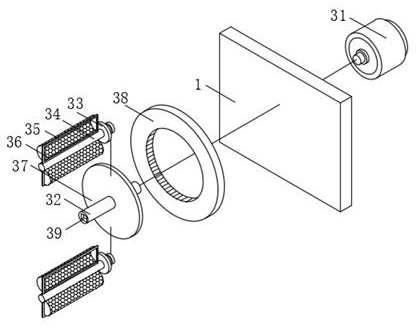

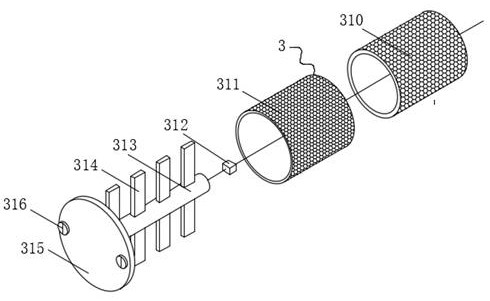

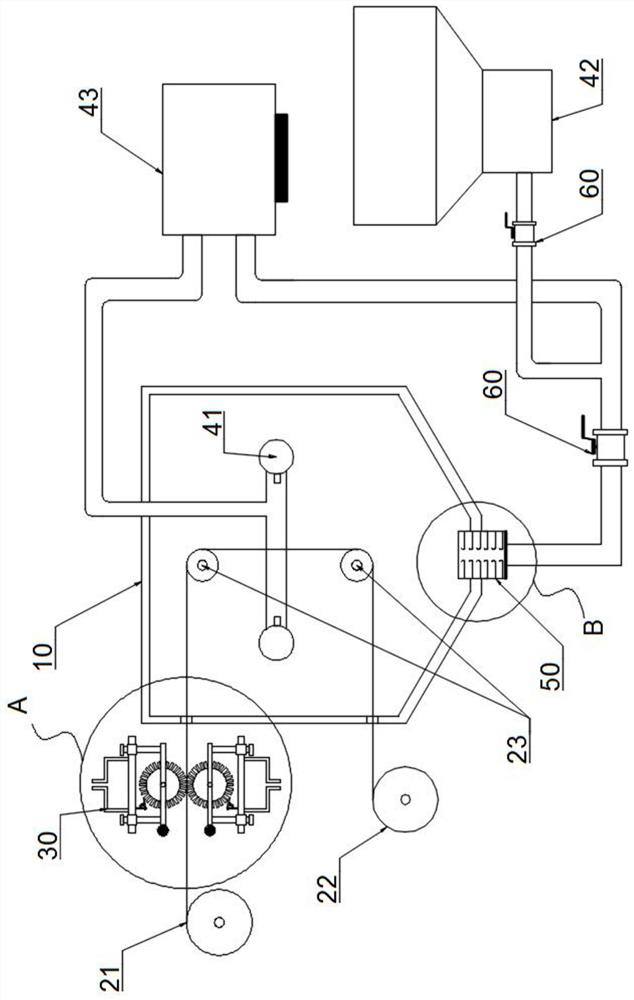

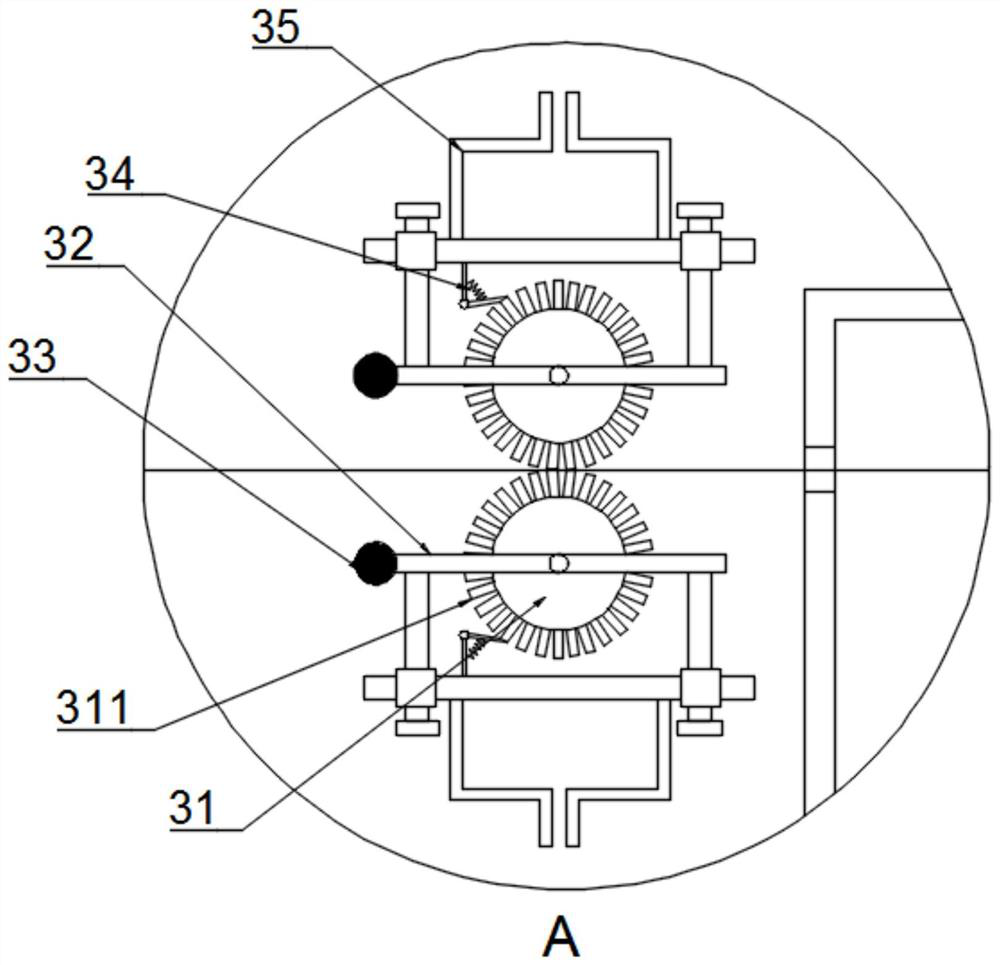

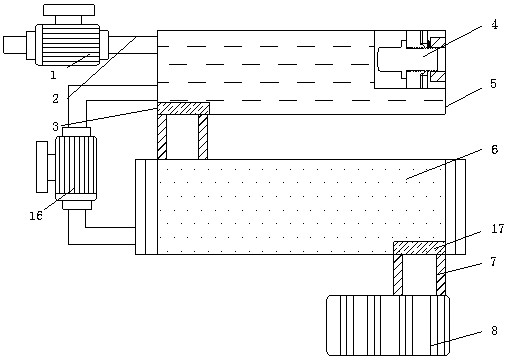

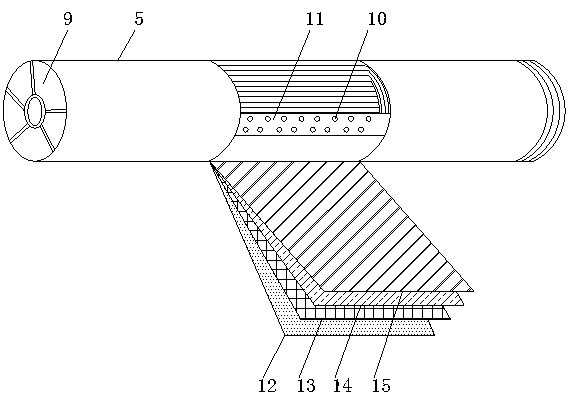

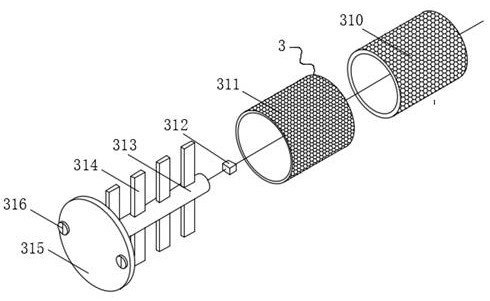

Device for continuous waterless dyeing of spindles by adoption of high-pressure supercritical fluid technology

ActiveCN105040318ANot subject to wear and tearIncrease stiffnessSolvent treatment with solvent recoveryTextile solvent-dyeingDissolutionProcess engineering

The invention relates to a device for continuous waterless dyeing of spindles by adoption of high-pressure supercritical fluid technology. The device is composed of spindle trolleys 1 in the number of 50 to 500, a horizontally-placed straight dyeing pipe 2, a hydraulic push rod 3, a dyeing pressurization system 4, a dye ingredient dissolving system 5, a dye recovery and carbon dioxide purifying system 6, a carbon dioxide pressurization system 7, a carbon dioxide storage tank 8, a depressurizing system 9 and a spindle trolley return trajectory 10. Four segments are divided by the dyeing pipe 2 based on operating conditions and respectively connected with a feeding segment 2 of the pressurization system 4, a dyeing segment 2 of the dye ingredient dissolving system, a cleaning segment 2 of the dye recovery and carbon dioxide purifying system and a discharge segment 2 of the depressurizing system in order.The dyeing segment is dyed by adoption of carbon dioxide dissolution dye for positive and opposite dyeing. The cleaning segment is used for cleaning spindles by adoption of clean supercritical fluid carbon dioxide as a cleaning fluid in a reverse flow mode. The discharge section enables pressure of the spindle trolley 1, passing the cleaning segment, to be reduced step by step at normal pressure. The device for continuous waterless dyeing of spindles by adoption of high-pressure supercritical fluid technology is used for waterless dyeing of spindles.

Owner:EAST CHINA UNIV OF SCI & TECH

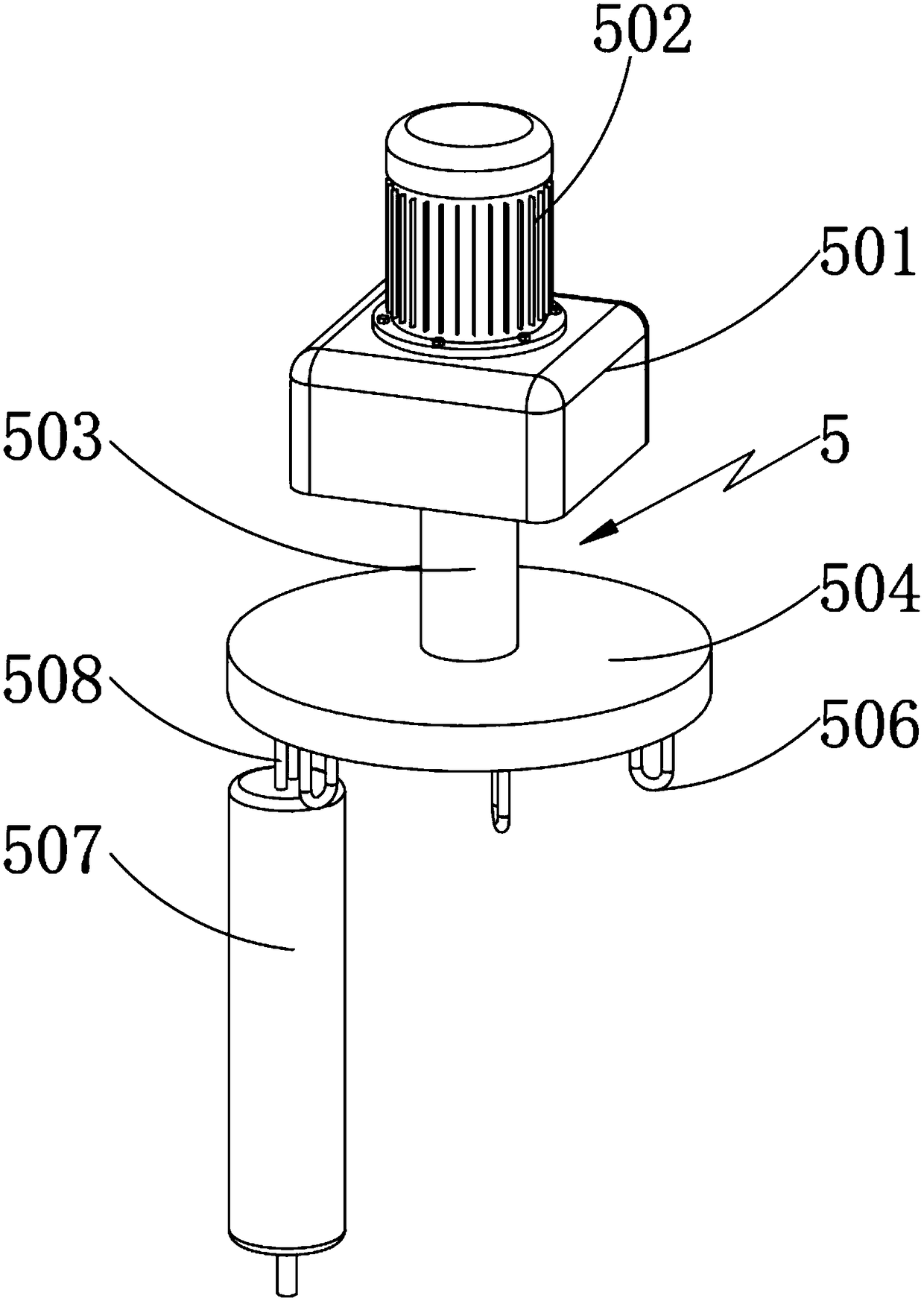

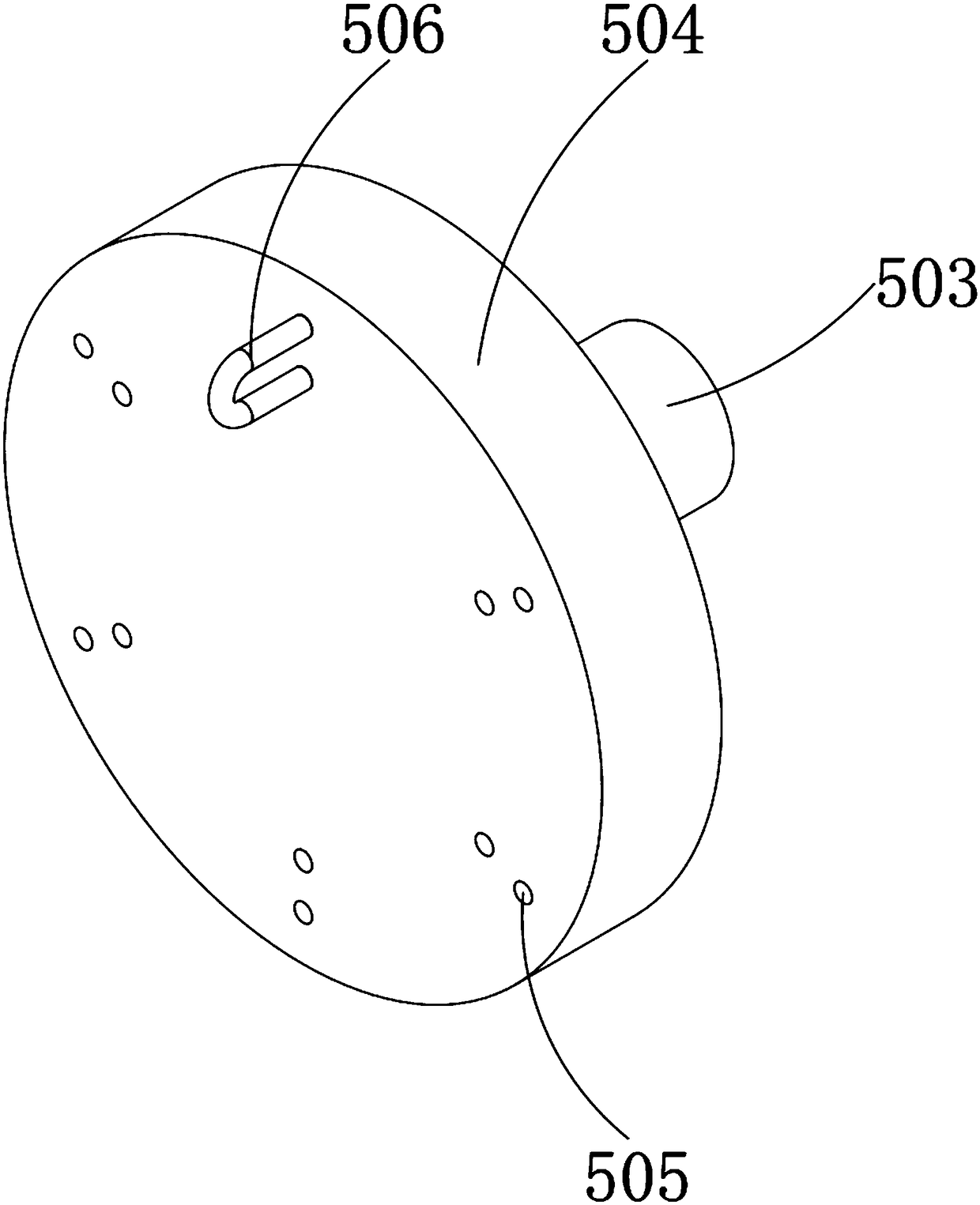

Coloring machine for colored spun yarns in textile field

PendingCN109281084AReduce wasteNot easy to fall offTextile treatment containersLiquid/gas/vapor removalYarnPulp and paper industry

The invention discloses a coloring machine for colored spun yarns in the textile field. The machine comprises a coloring cylinder, a motor, a spinning column, a spraying device, a dye storage box, a curing device, a locking device and a dye recovery device, one end of the coloring cylinder is a cavity structure with an opening, the upper end of the coloring cylinder is movably provided with a sealing plate through a rotary shaft, the locking device is arranged on the side, away from the rotary shaft, of the sealing cover plate and the coloring cylinder, a first supporting plate is fixedly welded to the part, close to the bottom, of the coloring cylinder, a plurality of through holes are formed in the first supporting plate, the motor is fixedly welded to the middle of the first supportingplate, a rotary plate is fixedly welded to a rotary shaft of the motor, the spinning column is of a cavity structure with openings at the two ends, and installing blocks are fixedly welded to the twosides of the bottom of the spinning column. The machine has the advantages that dye can be recycle, steaming color curing can be conducted on the dyed colored spun yarns, so that the dye does not easily fall, and the machine is extremely time saving and labor saving.

Owner:JIANGSU XINJINLAN TEXTILE GARMENT CO LTD

Inner and outer surface dyeing device for full absorption of garment cloth

InactiveCN112481883AAbsorb evenly and fullyAvoid pollutionTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringMechanical engineering

The invention provides an inner and outer surface dyeing device for full absorption of garment cloth. A connecting pipe is arranged in a soaking pool; a storage barrel is fixedly connected to the tailend of the connecting pipe; the storage barrel is fixedly mounted in the left and right sides of the soaking pool; a piston plate is slidably mounted in the storage barrel; a transverse rod is arranged at the top end of the piston plate; and the outer side surface of the transverse rod is located on the outer side of a swing plate. When a movable frame moves downwards, a support is driven to extrude a hot air bag, hot air makes contact with dyed cloth through a spray head, and therefore forming is rapidly carried out in first time after dyeing; when the movable rod swings to the innermost side, the swing plate extrudes the transverse rod, and the transverse rod drives the piston plate to push out dye in the storage barrel; and dye ascends in the soaking pool by the pressure intensity to immerse cloth on the surface of a pressing and covering roller, and after the movable rod swings to the outer side, the dye in the soaking pool is recycled into the storage barrel through the piston plate, so that the dye is prevented from being polluted after long-time dyeing operation.

Owner:广州汇诗服饰有限公司

Textile cloth dyeing device capable of automatically adjusting dip dyeing depth and recycling dye

InactiveCN113215758AReduced transit timeIncrease the depth of immersion in the dipping tankLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile manufacturingMechanical engineering

The invention relates to the technical field of textile manufacturing equipment, and discloses a textile cloth dyeing device capable of automatically adjusting dip dyeing depth and recycling dye. The textile cloth dyeing device comprises a dip dyeing pool; the surface of the dip dyeing pool is movably connected with a dip dyeing mechanism; the top of the dip dyeing mechanism is movably connected with an adjusting mechanism; the surface of the dip dyeing mechanism is movably connected with an extrusion mechanism; the bottom of the extrusion mechanism is fixedly connected with a recycling mechanism; the bottom of the extrusion mechanism is movably connected with a pressurizing mechanism; the top of the extrusion mechanism is movably connected with a connecting rod; when the rotating speed of a rotating roller is increased, the centrifugal force is increased, a telescopic rod pushes a rotating rod towards the outer side, the rotating rod drives an arc-shaped plate to push the rotating roller to move downwards, and the cloth dip dyeing depth is increased; and the dip dyeing time of the cloth is kept, a Y-shaped rod reciprocates through rotation of the rotating roller, two sets of pressing rollers rotate reversely to extrude out dye in the cloth and squeeze redundant dye into a recycling pool, and then the dye is recycled into the dip dyeing pool in cooperation with reciprocating scraping of a scraping plate.

Owner:济南潘菲电子贸易有限公司

Stable textile dye recovery device

ActiveCN114133054AAchieve stirring effectEffect of purification effectSpecific water treatment objectivesWater contaminantsDisperse dyeDyeing wastewater

The invention discloses a stable textile dye recovery device, and belongs to the technical field of wastewater recovery, the stable textile dye recovery device comprises a wastewater tank, a filter tank, support legs and a guide plate, the upper surface of the wastewater tank is provided with a liquid inlet, the wastewater tank is internally provided with a treatment mechanism for dye recovery treatment, and the lower surface of the wastewater tank is provided with a water outlet; second sliding blocks are fixedly connected to the left side and the right side of the lower surface of the wastewater tank. According to the disperse dye wastewater treatment device, the treatment mechanism is arranged, a motor can drive a first rotating shaft to rotate when working, and the first rotating shaft can drive a circular plate to rotate when rotating, so that a second rotating shaft can rotate around a second net cylinder, the effect of stirring dye wastewater can be achieved, and condensed substances in the disperse dye wastewater can be effectively crushed; meanwhile, the dye wastewater can be collected by the collecting net, and large impurities such as floccules with large volumes can be well filtered out, so that the influence on the subsequent dye wastewater purification effect is avoided.

Owner:南通甘宇纺织有限公司

Environment-friendly felt dyeing device and technology with dye recycling structure

PendingCN110923989AShorten drying timeImprove dyeing efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsSolenoid valveEngineering

The invention discloses an environment-friendly felt dyeing device and technology with a dye recycling structure. The device comprises a dyeing box, an electric sliding table, a motor, a heater, a solenoid valve and a control switch, wherein a first fixed bracket is fixedly connected to the upper side of the dyeing box, and a discharge roller is arranged on the first fixed bracket, and first hookpieces are fixedly installed on outer surfaces of left and right ends of the discharge roller; a fixed rod is arranged below the discharge roller; and the fixing rod is fixedly installed on the dyeingbox. According to the device, a felt material is dyed by the way of pulling by one roller and winding up by the other roller; through setting clamping strength of a material tightening wheel to the felt material, in combination with a pull force of a wind-up roller, the felt material is stretched and refined, so that dyeing efficiency of the felt material is improved; the felt material is dyed layer by layer in a winding manner, so that the dyeing efficiency is further improved; and by being matched with a reverse collection bracket for draining the dyed felt material, the device is greatly reduced in dry time of the felt material.

Owner:湖州练市富腾绒毛有限公司

Novel dyeing machine for spinning

InactiveCN112593352ASpeed up dryingImprove drying efficiencyLiquid/gas/vapor removalTextile treatment machine arrangementsSpinningDye recovery

The invention discloses a novel dyeing machine for spinning. The novel dyeing machine for spinning comprises a dyeing machine body and a drying machine; a cloth inlet is formed in the side face of thedyeing machine body; supporting legs are fixedly arranged on the lower surface of the dyeing machine body; a cleaning door is arranged in the dyeing machine body in a sliding mode; a dye recycling box is arranged at the lower end of the dyeing machine body; a filter plate is arranged in the dyeing machine body in a sliding mode and located over the dye recycling box; rollers are rotationally arranged on the dyeing machine body and the drying machine; the rollers are distributed in the dyeing machine body and the drying machine in a mirroring mode; the two ends of each roller are fixedly sleeved with first bearings; and the first bearings are fixedly mounted in the dyeing machine body and the drying machine; Compared with the prior art, a drying lamp is arranged, the drying lamp is fixedlyarranged in the drying machine, the drying lamp can be used for heating, and the temperature in the drying machine is increased, and therefore cloth can be dried in the drying machine.

Owner:安徽君翰纺织科技有限公司

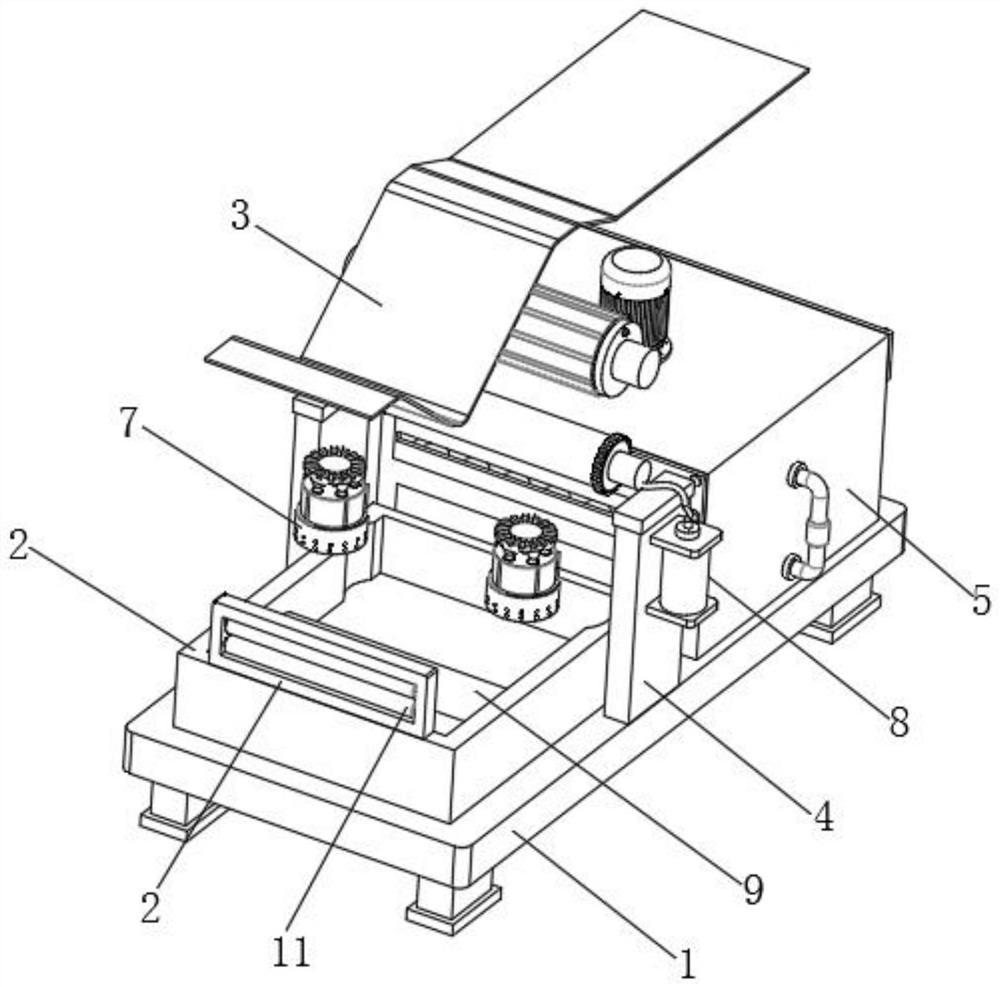

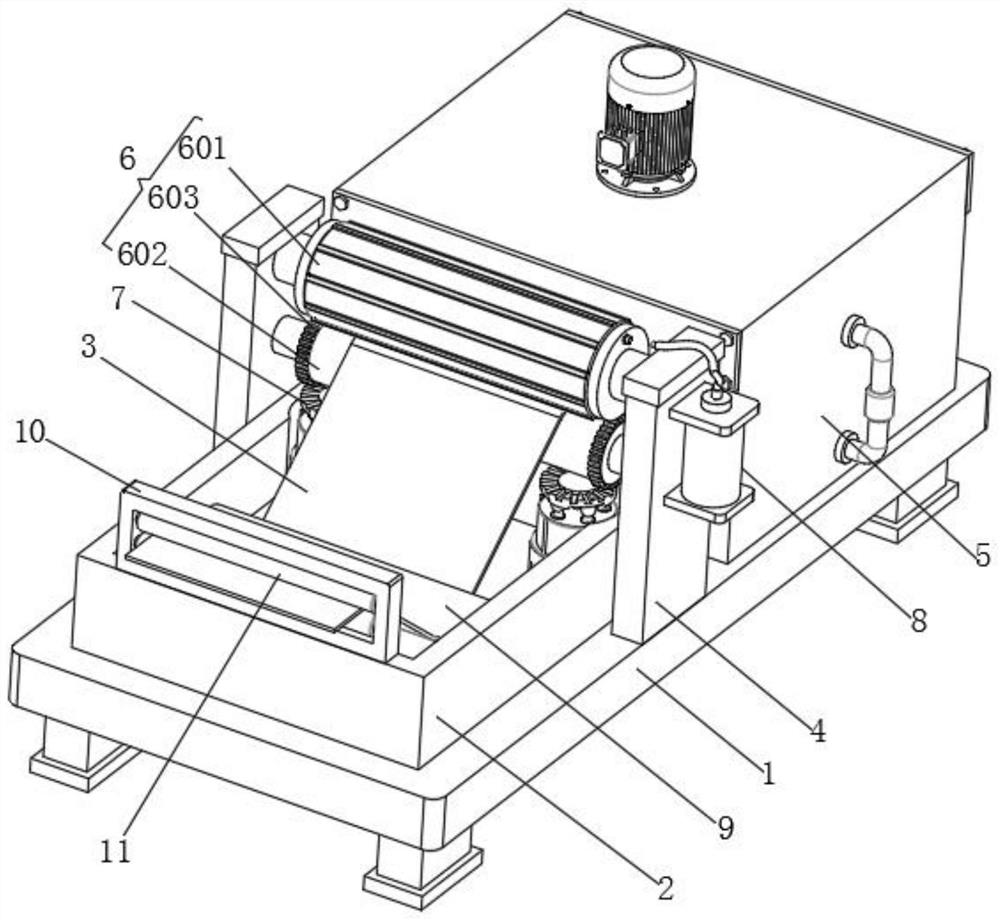

Cloth dyeing machine capable of effectively recycling dye

PendingCN112726052AReduce pollutionEffective filteringMechanical cleaningPressure cleaningEngineeringProcess engineering

The invention relates to a cloth dyeing machine capable of effectively recycling dye. The cloth dyeing machine comprises a machine body, an unwinding roller, a winding roller, two guide rollers, two groups of pre-cleaning devices, a spray dyeing device, a filter and two discharge valves, wherein a cloth roll to be spray-dyed is mounted on the unwinding roller; and cloth sequentially passes through the pre-cleaning devices, an inlet of the machine body, the two guide rollers, an outlet of the machine body and the winding roller, and then is wound by the winding roller. By arranging the two groups of pre-cleaning devices, thread ends on the surfaces of the two sides of the cloth can be pre-cleaned before the cloth enters the cloth dyeing machine body, so that the pollution to the dye in the cloth dyeing machine is reduced; and by arranging the filter, the dye in the cloth dyeing machine body can be effectively filtered before being recycled, so that the dye mixed with the thread ends is prevented from flowing back to be reused and blocking a spray pipe in the spray dyeing device.

Owner:江门市新会区叶润纺织有限公司

Dye recycling circulation filtering device for textile dyeing machine

PendingCN107857407AAvoid side effectsRealize automatic operationWater treatment parameter controlWater/sewage treatment by irradiationLoop filterSolenoid valve

The invention discloses a dye recycling circulation filtering device for a textile dyeing machine. The dye recycling circulation filtering device comprises a water pump, an oxidation pond, a filter pipe, a collection box and a permeate core column, wherein the water pump is connected with the oxidation pond on the right side through a pipeline; a water level measuring apparatus is fixed in the oxidation pond; a first electromagnetic valve is mounted at the bottom of the inner wall of the oxidation pond; the downside of the first electromagnetic valve is connected with the filter pipe below through a water pipe; a second electromagnetic valve is mounted on the inner wall of the bottom of the filter pipe; the second electromagnetic valve is connected with the collection box below through a water pipe; the two ends of the filter pipe are sealed by sealing covers. According to the dye recycling circulation filtering device disclosed by the invention, automatic operation is controlled by PLC; in the case of high water level in the oxidation pond, a yielding water self-priming pump runs, the water pump draws water outward, and the water level in the oxidation pond goes down; in the caseof low water level in the oxidation pond, the PLC controls the water pump to pump water into the oxidation pond; therefore, automatic operation is realized.

Owner:新乡市新科防护科技有限公司

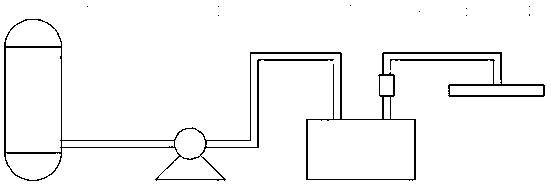

Method and device for recovering indigoid dye

ActiveCN102531224AImprove recycling efficiencyReduce turbidityWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentProgrammable logic controllerWastewater

The invention relates to a method and a device for recovering an indigoid dye. The method for recovering the indigoid dye is characterized by comprising the following steps of: (1) introducing waste water into a non-woven fabric filter for filtering; (2) pumping the filtered waste water into an oxidizing pond, blowing and aerating in the oxidizing pond, and adding sulfuric acid under the control of a PLC (Programmable Logic Controller) till the pH is between 5 and 8; (3) aerating a flat plate film assembly in the filtering pond to prevent solid particles from being gathered on a film and lowering the film flux, and adding sulfuric acid under the control of the PLC till the pH between 3 and 6; (4) running the film assembly in way of running for T1 minutes and pausing for T2 minutes; (5) discharging a concentrated solution which is concentrated by 10 times through a groove at the bottom of a filtering pond for recovering; and (6) running a water-producing self-sucking pump under the control of the PLC when the filtering pond is at a high water level, opening a battery valve between the filtering pond and the oxidizing pond when the filtering pond is at a low water level, and opening a raw water self-sucking pump for realizing automatic running when the oxidizing pond is at a low water level. The method and the device have the characteristic of good dye recovering effect.

Owner:江苏常环环境科技有限公司

Linen fabric dyeing device

InactiveCN112647221ALower heating costsTimely recyclingTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringProcess engineering

The invention relates to the technical field of fabric production equipment, in particular to a linen fabric dyeing device which comprises a dip dyeing barrel and a dip dyeing barrel support, wherein the dip dyeing barrel is connected with the dip dyeing barrel support through a shaft pin and a bolt, a layer of heating cavity is formed in the outer wall of the dip dyeing barrel, a linen compression roller support and a linen guide roller support are symmetrically arranged at the top of the dip dyeing barrel, and a dye recovery device is connected below the linen guide roller support. According to the linen dyeing device, steam heating is adopted, so that the heating cost is low, and thus the dyeing cost is reduced; the dye recycling device is connected to the lower portion of the linen guide roller support, so that when linen enters a next procedure after dip dyeing, dye on the linen can be recycled in time, and the utilization rate of the dye is increased; and a heat preservation layer is arranged on the outer wall of the heating cavity, and due to the structural design of the heat preservation layer, steam heat losses are reduced, and the dyeing cost is further reduced.

Owner:XUZHOU PUSU INTERIOR DECORATION MATERIAL CO LTD

Chemical fiber cloth fabric suspension device

InactiveCN109208217AFast dryingEasy to fixLiquid/gas/vapor removalTextile treatment carriersChemical fiber clothElectric machinery

The invention discloses a chemical fiber cloth fabric suspension device, comprising a bottom plate. An electric telescopic rod is mounted at each corner of the upper surface of the bottom plate. A topplate is welded to the top ends of the electric telescopic rods. Suspension assemblies are mounted equidistantly in the middle of the top plate. A dye recovery assembly is mounted in the middle of the upper surface of the bottom plate. Dustproof assemblies are mounted equidistantly at the edge portion of the top plate. According to the invention, the chemical fiber cloth fabric suspension deviceis scientific and reasonable in structure and safe and convenient in use, electric disks are driven to rotate by driving motors, so that fabric reels suspended below the electric disks rotate, the aircirculation around the fabric reels is increased so that the drying rate of the chemical fiber fabric wrapped around the outer side of each suspended fabric reel is accelerated, the production efficiency of the chemical fiber fabric is improved, the fixing of the fabric reels is facilitated through the attraction between the electric disks and fixing rings, the fabric reels can be prevented frombeing thrown away during the rotation of the electric disks, and the stability of the chemical fiber fabric in the suspension process is improved.

Owner:长兴一盛纺织有限公司

A stable recycling device for textile dyes

ActiveCN114133054BAchieve stirring effectEffect of purification effectSpecific water treatment objectivesWater contaminantsDisperse dyeDyeing wastewater

Owner:南通甘宇纺织有限公司

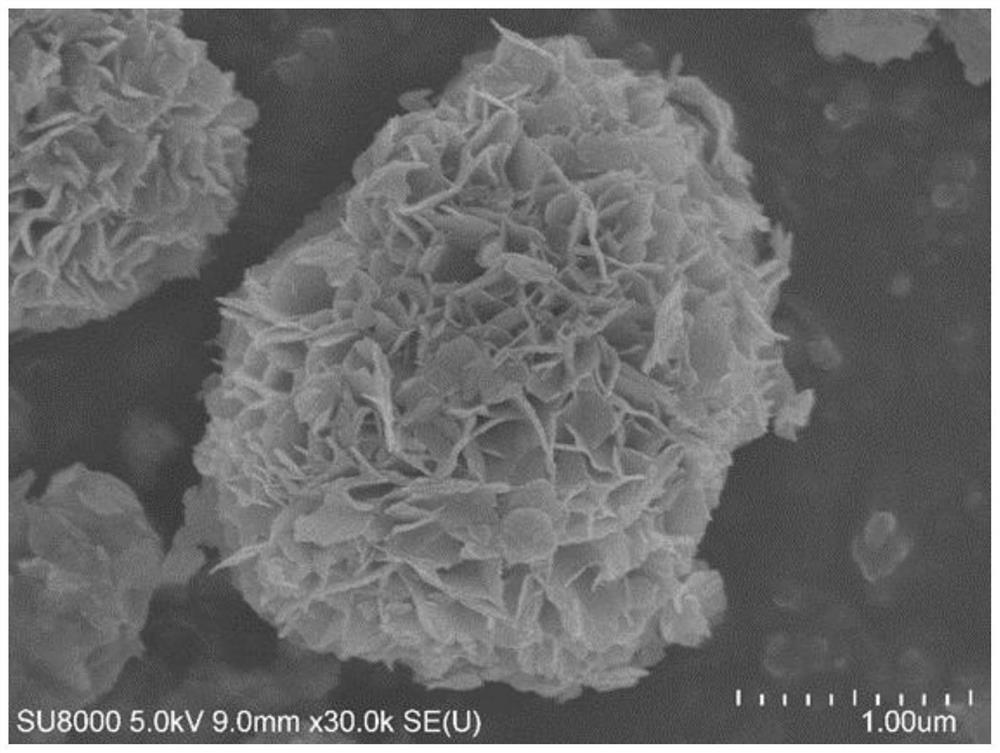

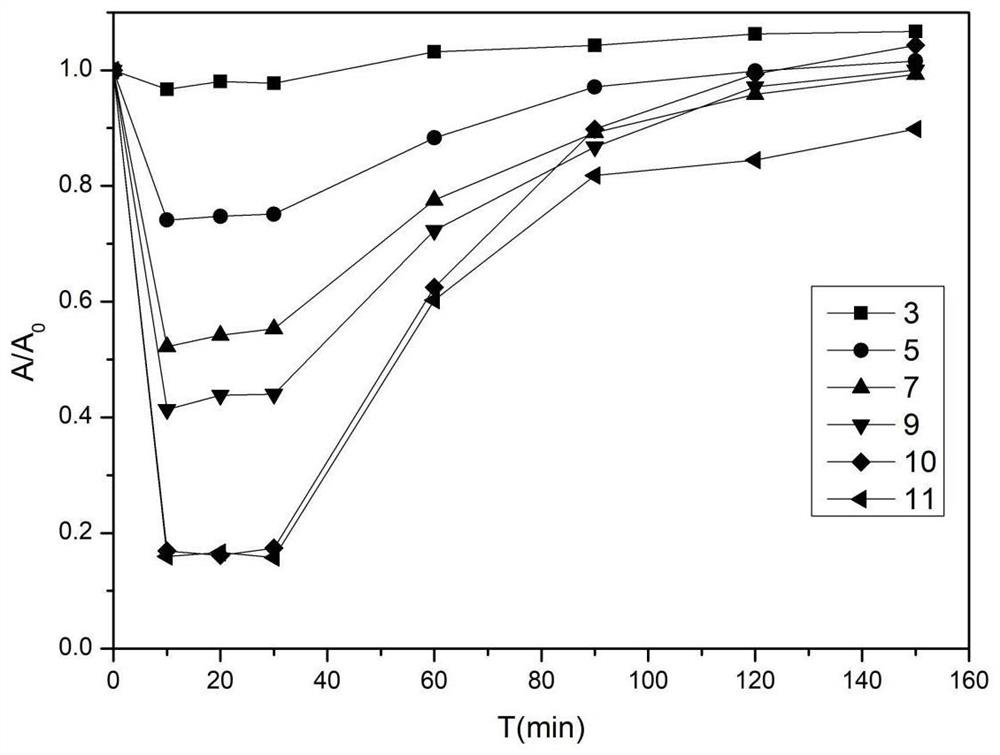

Dye recovery material without secondary pollution, preparation method thereof and dye recovery method

PendingCN114471469AAchieve desorption effectEasy to operateOther chemical processesWater contaminantsFormateDye recovery

The invention discloses a preparation method of a dye recovery material without secondary pollution, which comprises the following steps: adding bismuth nitrate pentahydrate into a mixed solution, and carrying out ultrasonic treatment and stirring to dissolve the bismuth nitrate pentahydrate; reacting in a polytetrafluoroethylene hydrothermal reaction kettle, cooling, centrifuging, washing and drying to obtain bismuth formate oxide; adding bismuth formate into the mixed solution, and carrying out ultrasonic treatment and stirring until bismuth formate is dissolved; the preparation method comprises the following steps: dissolving citric acid in water, mixing the two solutions, adjusting the pH value, reacting in a polytetrafluoroethylene hydrothermal reaction kettle, cooling, centrifuging, washing and drying to obtain the dye recovery material. The material prepared by the invention can realize the desorption effect on pollutants only by illumination, and has the outstanding advantages of easiness in control, no secondary pollution and the like.

Owner:HENAN NORMAL UNIV

Cotton yarn space dyeing equipment facilitating dye recovery

PendingCN113818165AImprove the efficiency of section dyeingLow costTextile treatment machine arrangementsTextile treatment cleaning apparatusYarnDye recovery

The invention discloses cotton yarn space dyeing equipment facilitating dye recovery, and relates to the technical field of related equipment for spinning. The cotton yarn space dyeing equipment facilitating dye recovery comprises a mounting mechanism, space dyeing mechanisms, material receiving mechanisms and material cleaning mechanisms, wherein the space dyeing mechanisms are connected to the centers of the two sides of the mounting mechanism; space dyeing assemblies and feeding assemblies of the space dyeing mechanisms are arranged at the inner ends and the outer ends of the two sides of the mounting mechanism correspondingly; winding and unwinding mechanisms are movably connected to the two sides of the mounting mechanism through movable mechanisms; the material receiving mechanisms are slidably connected to the lower parts of the inner sides of the winding and unwinding mechanisms; and the material cleaning mechanisms are in threaded connection to the edges of the top ends in the feeding assemblies at equal intervals. According to the cotton yarn space dyeing equipment facilitating dye recovery provided by the invention, by arranging the space dyeing mechanisms, the material receiving mechanisms and the material cleaning mechanisms, the problems that existing cotton yarn space dyeing equipment is low in cotton yarn space dyeing efficiency and high in cost, the angle of a cleaning structure needs to be manually adjusted to meet the cleaning requirement, long-time manual control causes aching pain of arms of a human body, and the cleaning structure is integrally arranged to cause inconvenience in disassembly, assembly and replacement are solved.

Owner:徐州万丰纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com