Aramid loose nanofiltration membrane as well as preparation method and application thereof

A technology of nanofiltration membrane and aramid fiber, which is applied in the field of membrane separation, can solve the problems of high operating pressure, low dye purity, and high energy consumption of nanofiltration membranes, and achieve significant interception effect, low salt interception rate, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing an aramid loose nanofiltration membrane, comprising the following steps:

[0028] 1) Preparation of aramid nanofiber spinning solution: Soak 1g of para-aramid fiber in 200mL of 1% potassium hydroxide solution, stir at 80°C for 2h, wash with deionized water and dry Add the dried fiber fragments to 500mL of dimethylformamide, and continue to stir at a speed of 200rpm for 3h to obtain the aramid fiber spinning solution;

[0029] 2) Preparation of hydrophilic aramid fiber sol: add the aramid nanofiber spinning solution obtained in step 1) dropwise into a phosphoric acid solution with a mass fraction of 3% according to the dosage ratio of 1g:1000mL, let stand for 12h, and continue Stirring at a speed of 300rpm for 1h, and then ultrasonically treating for 2h to obtain a hydrophilic aramid nanofiber sol;

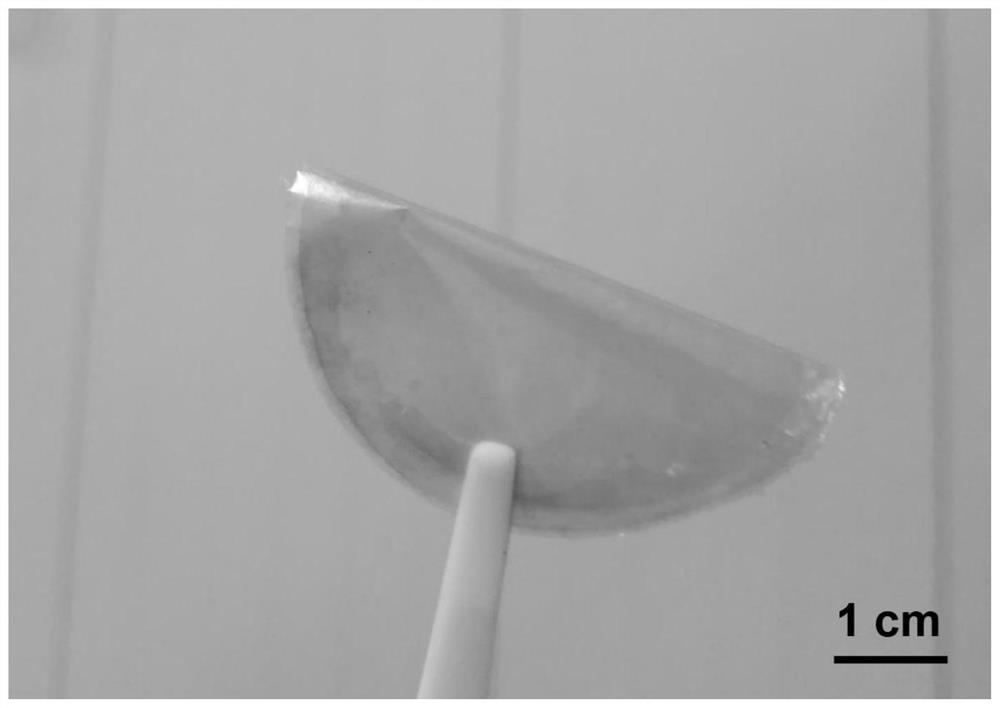

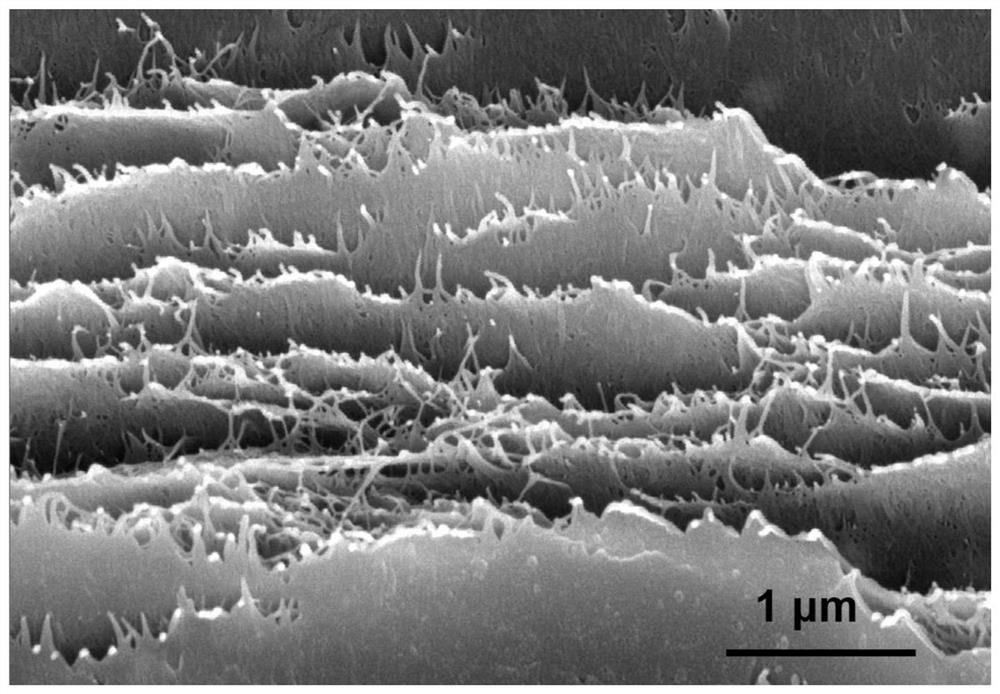

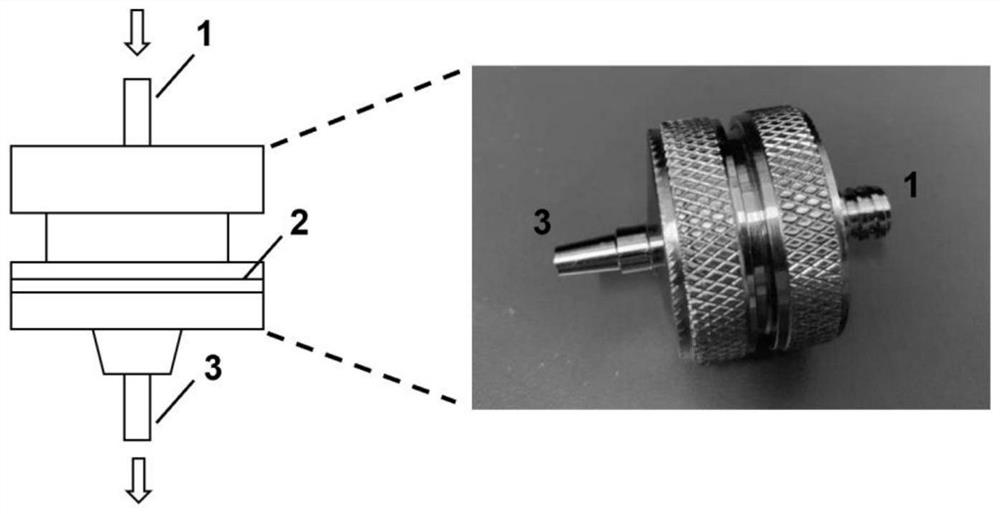

[0030] 3) Preparation of aramid loose nanofiltration membrane: take a certain mass of the hydrophilic aramid nanofiber sol o...

Embodiment 2

[0032] This embodiment provides a method for preparing an aramid loose nanofiltration membrane, comprising the following steps:

[0033] 1) Preparation of aramid nanofiber spinning solution: Soak 1 g of para-aramid fiber in 400 mL of 1% potassium hydroxide solution, stir at 80°C for 1 h, wash with deionized water and dry Add the dried fiber fragments to 800mL of dimethylformamide, and continue to stir at a speed of 500rpm for 2h to obtain the aramid fiber spinning solution;

[0034] 2) Preparation of hydrophilic aramid fiber sol: add the aramid nanofiber spinning solution obtained in step 1) dropwise into a phosphoric acid solution with a mass fraction of 5% according to the dosage ratio of 1g:2000mL, let stand for 8h, and continue Stirring at a speed of 100rpm for 2h, and then ultrasonically treating for 5h to obtain a hydrophilic aramid nanofiber sol;

[0035] 3) Preparation of aramid loose nanofiltration membrane: take a certain mass of the hydrophilic aramid nanofiber sol...

Embodiment 3

[0037] This embodiment provides a method for preparing an aramid loose nanofiltration membrane, comprising the following steps:

[0038] 1) Preparation of aramid nanofiber spinning solution: Soak 1 g of para-aramid fiber in 400 mL of 1% potassium hydroxide solution, stir at 80°C for 1 h, wash with deionized water and dry Add the dried fiber fragments to 300mL of dimethylformamide, and continue to stir at a speed of 3500rpm for 1h to obtain the aramid fiber spinning solution;

[0039] 2) Preparation of hydrophilic aramid fiber sol: add the aramid nanofiber spinning solution obtained in step 1) dropwise into a phosphoric acid solution with a mass fraction of 10% according to the dosage ratio of 1g:3000mL, let stand for 12h, and continue Stir at a speed of 200rpm for 1.5h, and then ultrasonically treat for 3.5h to obtain a hydrophilic aramid nanofiber sol;

[0040] 3) Preparation of aramid loose nanofiltration membrane: take a certain mass of the hydrophilic aramid nanofiber sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com