Coloring machine for colored spun yarns in textile field

A technology in the field of color spinning, applied in the field of color spinning processing devices, can solve the problems of waste, time-consuming and laborious, and poor coloring effect, and achieve the effects of reducing leakage, reducing waste, and increasing coloring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

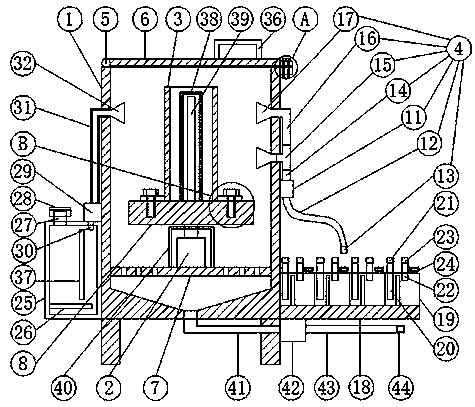

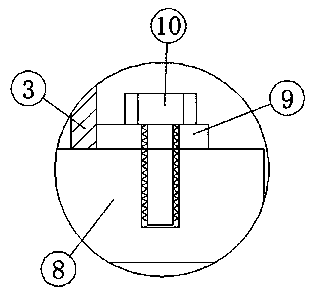

[0033] see Figure 1-4According to an embodiment of the present invention, a coloring machine for color spinning used in the textile field includes a coloring cylinder 1, a motor 2, a spinning column 3, a spraying device 4, a dye storage box 19, a color fixing device, a lock tightening device and dye recovery device, the coloring tube 1 is a cavity structure with an opening at one end, the upper end of the coloring tube 1 is provided with a sealing cover 6 through a rotating shaft 5, and the sealing cover 6 and the The coloring tube 1 is provided with a locking device on the side away from the rotating shaft 5, and a first support plate 7 is fixedly welded near the bottom end of the coloring tube 1. The first support plate 7 has a number of perforations. A motor 2 is fixedly welded on the middle part of the first support plate 7, a turntable 8 is fixedly welded on the rotating shaft 5 of the motor 2, the spinning column 3 is a cavity structure with openings at both ends, and t...

Embodiment 2

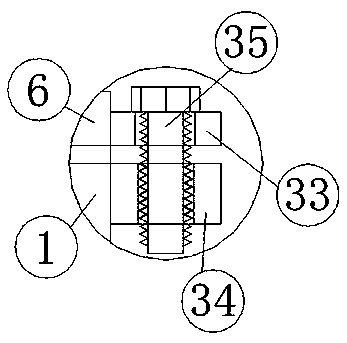

[0036] see figure 1 and 2 , for the coloring tube 1, the bottom end of the inside of the coloring tube 1 is set as an inverted cone; for the locking device, the locking device includes a first fixing block 33, and the first fixing block 33 is welded on the side of the sealing cover plate 6 away from the rotating shaft 5, the upper end of the coloring tube 1 away from the rotating shaft 5 is fixedly welded with a second fixing block 34, and the first fixing block 33 is connected to the rotating shaft 5. The second fixing blocks 34 are all processed with threaded holes, and the first fixing block 33 and the second fixing block 34 are fixedly connected by second bolts 35 .

[0037] Through the above solution of the present invention, the sealing cover plate 6 and the coloring cylinder 1 can form a sealed space to reduce the leakage of steam.

Embodiment 3

[0039] see figure 1 , for the sealing cover plate 6, a handle 36 is fixedly welded on the sealing cover plate 6; for the charging port 24, a cover is screwed on the charging port 24; for the steam box 25, the steam The box 25 is a double-layer structure, and the sealed space between the two layers of the steam box 25 is evacuated; for the dye storage box 19, a visible Window 37; for the turntable 8, a heating pipe sleeve 38 is fixedly welded in the center of the turntable 8, and a heating pipe 39 is installed in the heating pipe sleeve 38.

[0040] Through the above scheme of the present invention, it is convenient to open the sealing cover plate 6, so that the steam box 25 will not scald the workers, and the liquid level situation inside the dye storage box 19 and the steam box 25 can be observed in real time, so as to add materials in time, and can be used during dyeing and fixing. After coloring, the colored spinning yarn is dried, and the heating tube 39 can be prevented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com