Device and method for realizing printing and dyeing dyed wastewater reuse and dye recovery

A technology for dyeing wastewater and wastewater collection, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing the production water consumption and wastewater discharge per unit product, reducing the treatment load, and ensuring the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

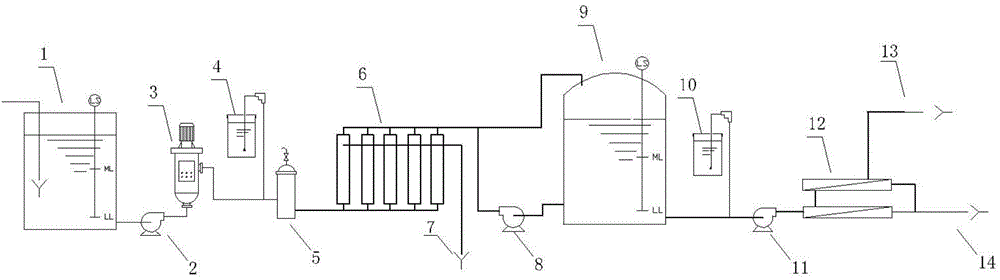

[0036] The raw water entering the dyeing wastewater reuse and dye recovery unit is the wastewater discharged from the dyeing section of reactive dyes. Water quality: COD≤120mg / L, suspended solids≤20mg / L, chroma≤480 (times), conductivity≤12ms / cm (mostly sodium ions and chloride ions, containing a small amount of calcium, magnesium, iron, hydroxide , sulfate ion).

[0037] The device includes two parts: pretreatment and membrane concentration recovery system.

[0038] Pretreatment includes self-cleaning filter, precision filter and ultrafiltration membrane device: self-cleaning filter is used to remove large particle suspended matter and mechanical impurities, effluent suspended matter 5mg / L; precision filter removes remaining suspended matter (suspended COD) and impurities, suspended matter in the effluent is 0; the ultrafiltration membrane device removes bacteria, colloids, macromolecular organic matter and part of the chroma, the effluent COD is 50mg / L, and the chroma is 380...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com