Dye recovery material without secondary pollution, preparation method thereof and dye recovery method

A technology for recycling materials and secondary pollution, applied in separation methods, water pollutants, chemical instruments and methods, etc., can solve problems such as large energy consumption and secondary pollution, achieve high-efficiency recovery, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

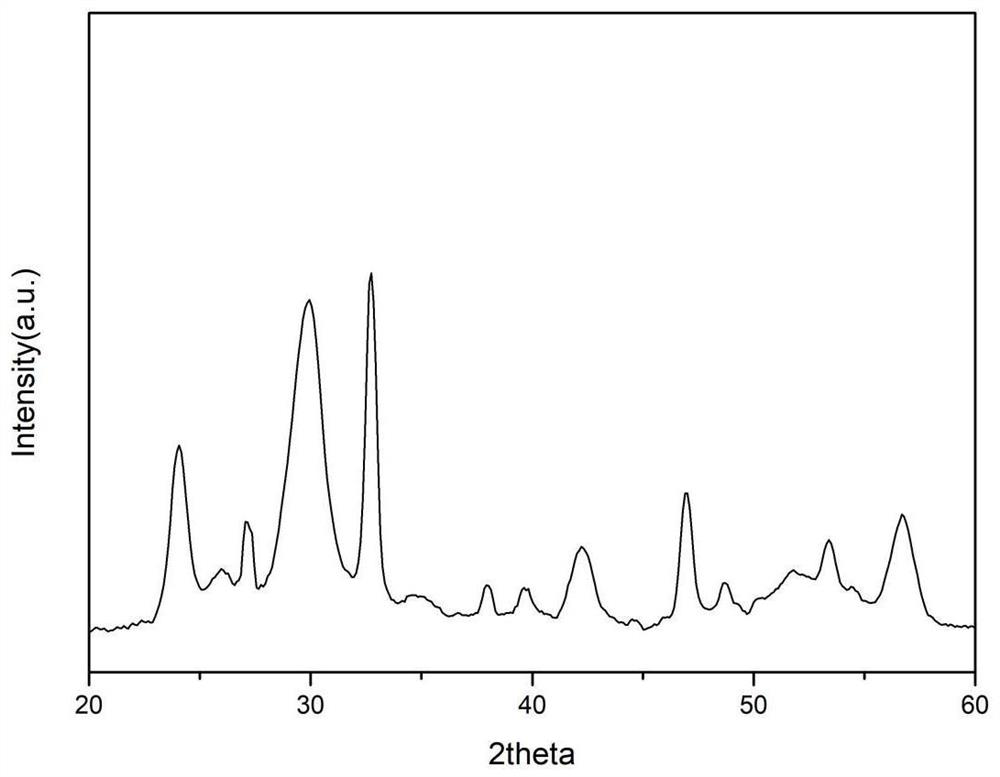

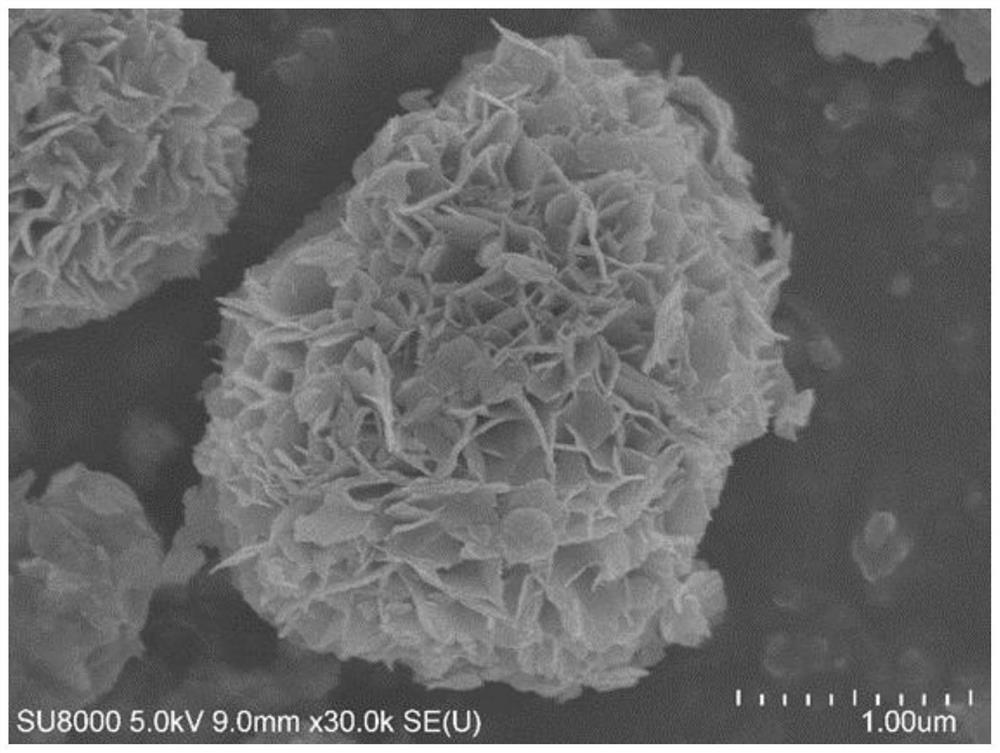

[0037] A preparation method of a dye recovery material without secondary pollution, comprising the following steps:

[0038] (1) Preparation of oxybismuth formate: Add 0.97014g of bismuth nitrate pentahydrate to a mixed solution consisting of 25ml of glycerol, 5ml of water and 10ml of N,N-dimethylformamide. Stir for 1 min to completely dissolve bismuth nitrate pentahydrate; put the dissolved mixed solution into a polytetrafluoroethylene hydrothermal reactor, react at 160°C for 15 hours, then cool naturally to room temperature, and centrifuge at 10,000r / min. Washing with deionized water and ethanol, and repeating 3 times; drying at 60°C to constant weight to obtain bismuth oxyformate;

[0039] (2) Modification of oxybismuth formate: Add 0.5 g of oxybismuth formate to a mixed solution consisting of 25 ml of glycerol, 5 ml of water and 10 ml of N,N-dimethylformamide, and simultaneously ultrasonicate the solution at 50 kHz and 400 r Dissolve oxybismuth formate completely under th...

Embodiment 2

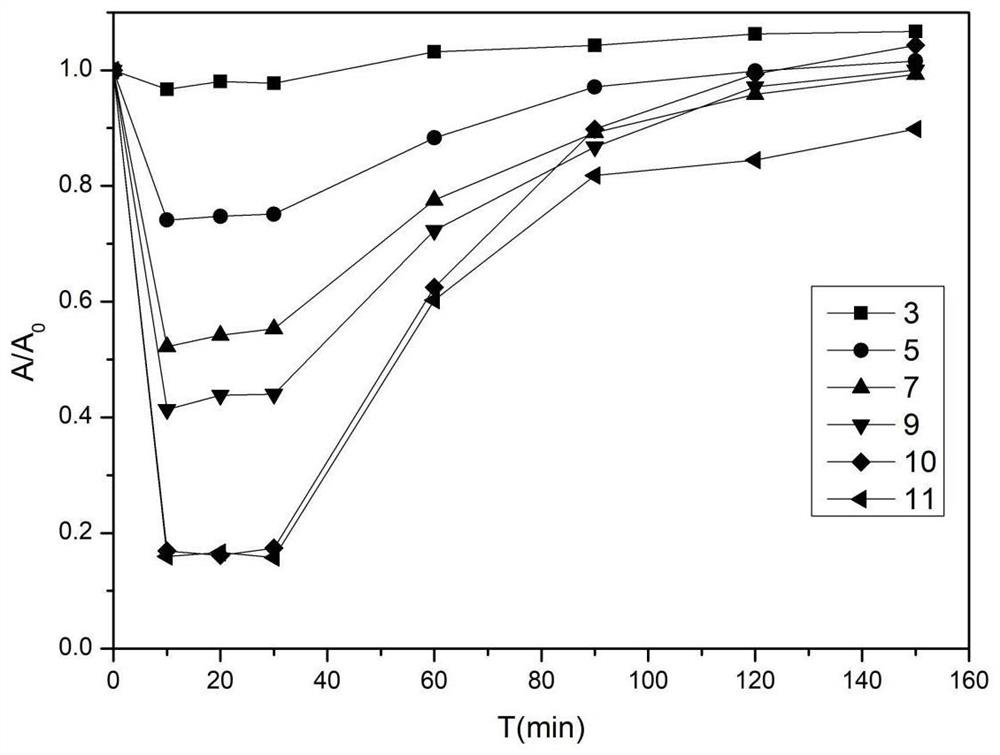

[0041] Measure volume and be 50mL, concentration is the methylene blue solution of 10mg / L, by using nitric acid or sodium hydroxide solution, the pH value of methylene blue solution is adjusted to 7, then takes by weighing 0.025g of the material prepared in Example 1, and it is ultrasonically dispersed in The adsorption reaction was carried out in the dark under the methylene blue dye solution. After the adsorption equilibrium (adsorption rate is 49%), the light source is turned on to 420nm visible light for desorption. The desorption rate is 90%.

Embodiment 3

[0043] Measure the methylene blue solution with a volume of 50 mL and a concentration of 10 mg / L, and adjust the pH value of the methylene blue solution to 9 by using nitric acid solution. Then 0.025 g of the material prepared in Example 1 was weighed, ultrasonically dispersed into the methylene blue dye solution, and the adsorption reaction was carried out under dark conditions. After the adsorption equilibrium (adsorption rate is 60%), light sources with a wavelength of 420 nm were used for desorption. The desorption rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com