Activated carbon for thickening methane in coal bed gas and preparation method of activated carbon

A technology of activated carbon and coalbed methane, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve problems such as adsorption and separation effects not mentioned, achieve sustainable development, simple preparation process, and alleviate environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] After the corncob is removed from the sponge floc layer, it is ground into a 200-mesh fine powder.

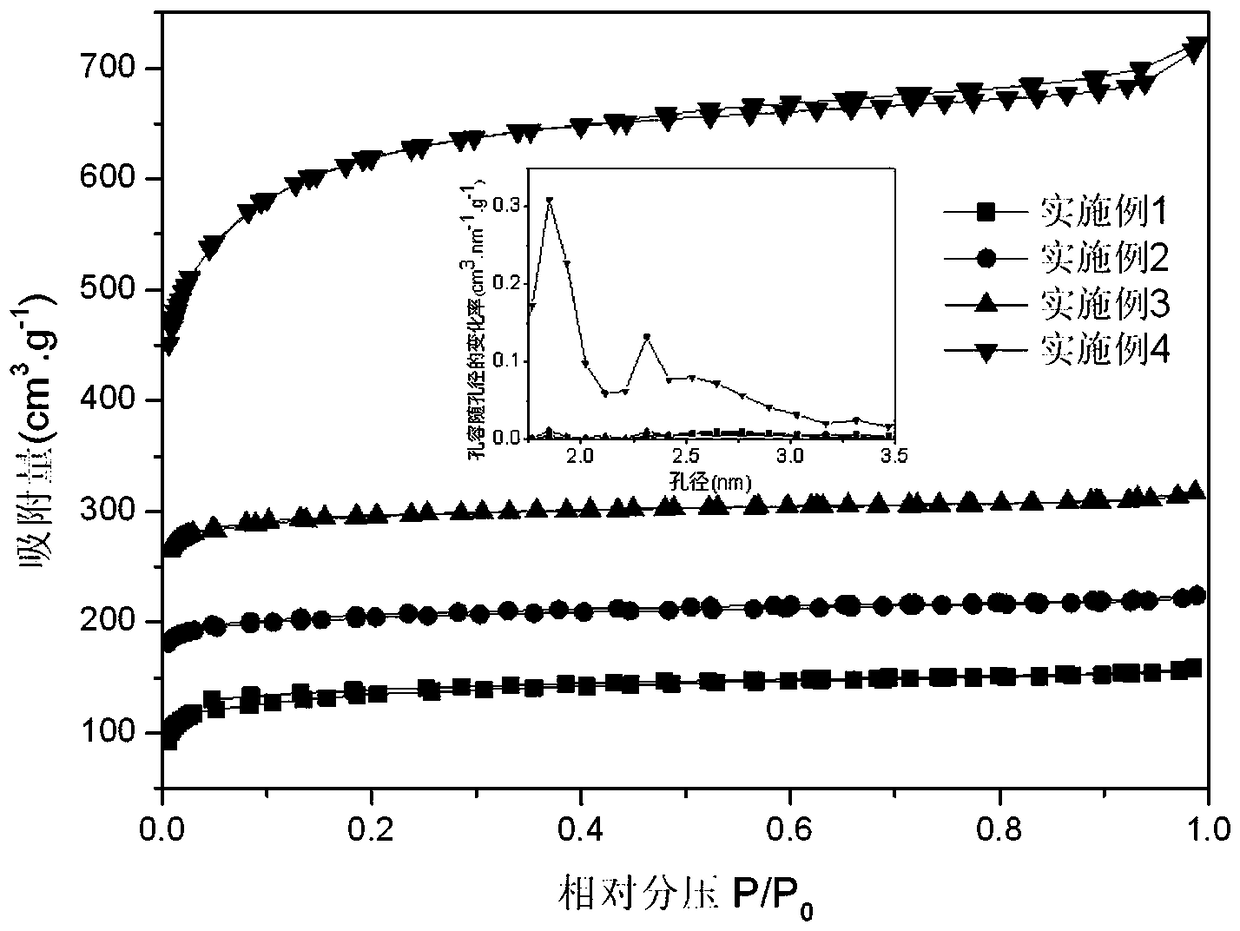

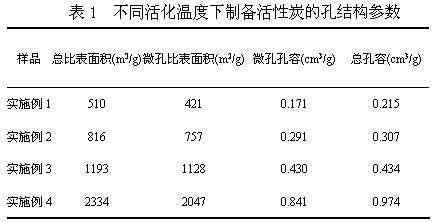

[0030] Weigh 5g of corncob fine powder and 2.5g of solid KOH, add them into 30g of distilled water, stir and mix evenly, dry at 180°C for 15h, and crush through a 20-mesh sieve. The pulverized sample was placed in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 500°C at a heating rate of 5°C / min, and activated by constant temperature roasting for 2h. The product is taken out, washed with water until neutral, and dried to obtain corncob activated carbon.

[0031] The prepared activated carbon was evacuated and degassed at 300°C for 3 hours, and the NOVA1200e adsorption instrument of Quantachrome Company in the United States was used to measure the CH 4 and N 2 Static adsorption capacity of pure component gases, respectively 14.4cm 3 / g and 3.9cm 3 / g,CH 4 / N 2 The equilibrium separation ratio was 3.7.

[0032]...

Embodiment 2

[0034] After the corncob is removed from the sponge floc layer, it is ground into a 200-mesh fine powder.

[0035] Weigh 5g of corncob fine powder and 2.5g of solid KOH, add them into 30g of distilled water, stir and mix evenly, dry at 180°C for 15h, and crush through a 20-mesh sieve. The pulverized sample was placed in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 600°C at a heating rate of 5°C / min, and activated by constant temperature roasting for 2h. The product is taken out, washed with water until neutral, and dried to obtain corncob activated carbon.

[0036] The prepared activated carbon was evacuated and degassed at 300°C for 3 hours, and the NOVA1200e adsorption instrument of Quantachrome Company in the United States was used to measure the CH 4 and N 2 Static adsorption capacity of pure component gases, respectively 26.6cm 3 / g and 7.4cm 3 / g,CH 4 / N 2 The equilibrium separation ratio is 3.6.

[0037] ...

Embodiment 3

[0039] After the corncob is removed from the sponge floc layer, it is ground into a 200-mesh fine powder.

[0040] Weigh 5g of corncob fine powder and 2.5g of solid KOH, add them into 30g of distilled water, stir and mix evenly, dry at 180°C for 15h, and crush through a 20-mesh sieve. The pulverized sample was placed in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 700°C at a heating rate of 5°C / min, and activated by constant temperature roasting for 2h. The product is taken out, washed with water until neutral, and dried to obtain corncob activated carbon.

[0041]The prepared activated carbon was evacuated and degassed at 300°C for 3 hours, and the NOVA1200e adsorption instrument of Quantachrome Company in the United States was used to measure the CH 4 and N 2 Static adsorption capacity of pure component gases, respectively 35.3cm 3 / g and 10.0cm 3 / g,CH 4 / N 2 The equilibrium separation ratio is 3.5.

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com