Adsorbing and desorbing method of multi-bed activated carbon adsorber

An activated carbon adsorption and adsorber technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as incomplete desorption, reduce the adsorption capacity of the adsorber, and exhaust exhaust gas exceeding the standard, so as to reduce the heat energy of desorption Loss, the effect of reducing the recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

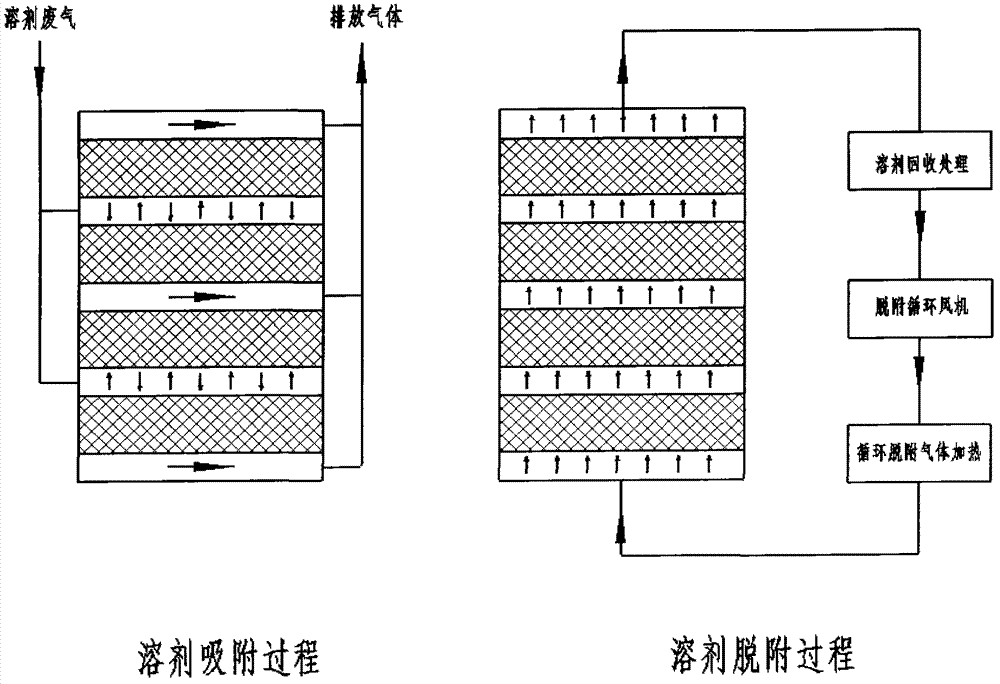

[0029] When the adsorber is adsorbing, switch the pipeline to realize the parallel operation of the activated carbon bed during adsorption. At this time, low-concentration and large-flow organic waste gas enters the adsorber. After the organic waste gas is adsorbed, the exhaust gas that meets the national emission standard is directly discharged. As the adsorption progresses, when the exhaust gas does not meet the standard, it will switch to the desorption process. At this time, through the switch between the adsorption gas pipeline and the desorption gas pipeline connected by the adsorber, the series operation of the activated carbon bed is realized, and the desorption gas After heating, it enters the adsorber for desorption. After the desorbed desorbed gas is discharged from the adsorber, it enters the subsequent treatment process (solvent recovery treatment), and the treated gas is sent to the heater for heating through the desorption circulation fan. desorption.

Embodiment 2

[0031] Most of the others are the same as in Example 1, and the only difference from Example 1 is that a plurality of independent single-bed adsorbers are used to replace a single multi-bed activated carbon adsorber.

Embodiment 3

[0033] Most of the others are the same as in Example 1, and the only difference from Example 1 is that a plurality of independent multi-bed adsorbers are used to replace a single multi-bed activated carbon adsorber. The specific pipeline switching method can be easily implemented by those skilled in the art with reference to the accompanying drawings, and does not require creative work, so it will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com