Carbon adsorbent for separating of methane and nitrogen and preparation method of carbon adsorbent

A technology of carbon adsorption and nitrogen, which is applied in the preparation of carbon adsorbents and the field of carbon adsorbents for the separation of CH4/N2, to achieve the effects of sufficient raw materials, alleviating environmental protection problems, and good desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After removing the sponge floc layer from the corn cob, crush it into a 200-mesh fine powder, mix it with a phosphoric acid solution with a concentration of 7.9% at a mass ratio of 1:6, dry it at 80°C for 40 hours, and crush it through a 60-mesh sieve. Place the pulverized sample in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 700°C at a heating rate of 10°C / min, and activated at a constant temperature for 2 hours. The product was taken out, washed with water until neutral, and dried to obtain a carbon adsorbent.

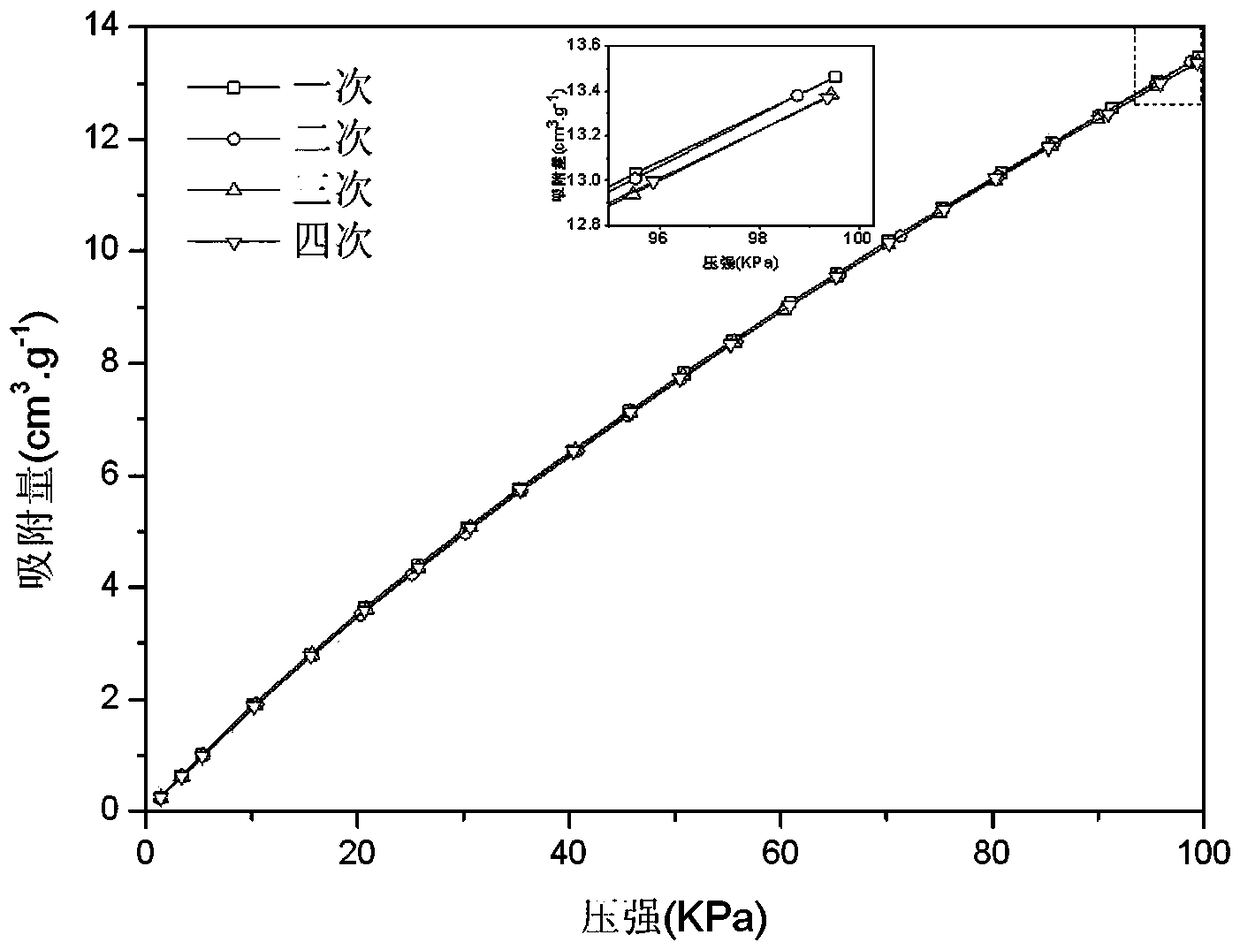

[0035] After vacuuming and degassing the carbon adsorbent prepared above at 300°C for 3 hours, the NOVA1200e adsorption instrument of Quantachrome Company in the United States was used to measure the CH 4 and N 2 Static adsorption capacity of pure components, respectively, 13.1 cm 3 / g and 3.5cm 3 / g,CH 4 / N 2 The equilibrium separation ratio was 3.7.

Embodiment 2

[0037] After removing the sponge floc layer from the corn cob, crush it into a 200-mesh fine powder, mix it with a phosphoric acid solution with a concentration of 17.9% at a mass ratio of 1:6, dry it at 80°C for 40 hours, and crush it through a 60-mesh sieve. Place the pulverized sample in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 700°C at a heating rate of 10°C / min, and activated at a constant temperature for 2 hours. The product was taken out, washed with water until neutral, and dried to obtain a carbon adsorbent.

[0038] According to the method of Example 1, measure carbon adsorbent to CH under 298K, 100Kpa 4 and N 2 The static adsorption capacity of the pure components is 13.8 cm 3 / g and 4.0cm 3 / g,CH 4 / N 2 The equilibrium separation ratio is 3.5.

Embodiment 3

[0040] After the sponge floc layer is removed from the corncob, it is crushed into a 200-mesh fine powder, mixed evenly with a phosphoric acid solution with a concentration of 27.9% at a mass ratio of 1:6, dried at 80°C for 40 hours, and crushed through a 60-mesh sieve. Place the pulverized sample in a muffle furnace, under the flow rate of 0.2L / min N 2 In the atmosphere, the temperature was raised to 700°C at a heating rate of 10°C / min, and activated at a constant temperature for 2 hours. The product was taken out, washed with water until neutral, and dried to obtain a carbon adsorbent.

[0041] According to the method of Example 1, measure carbon adsorbent to CH under 298K, 100Kpa 4and N 2 The static adsorption capacity of the pure components is 13.5 cm 3 / g and 4.0cm 3 / g,CH 4 / N 2 The equilibrium separation ratio was 3.4.

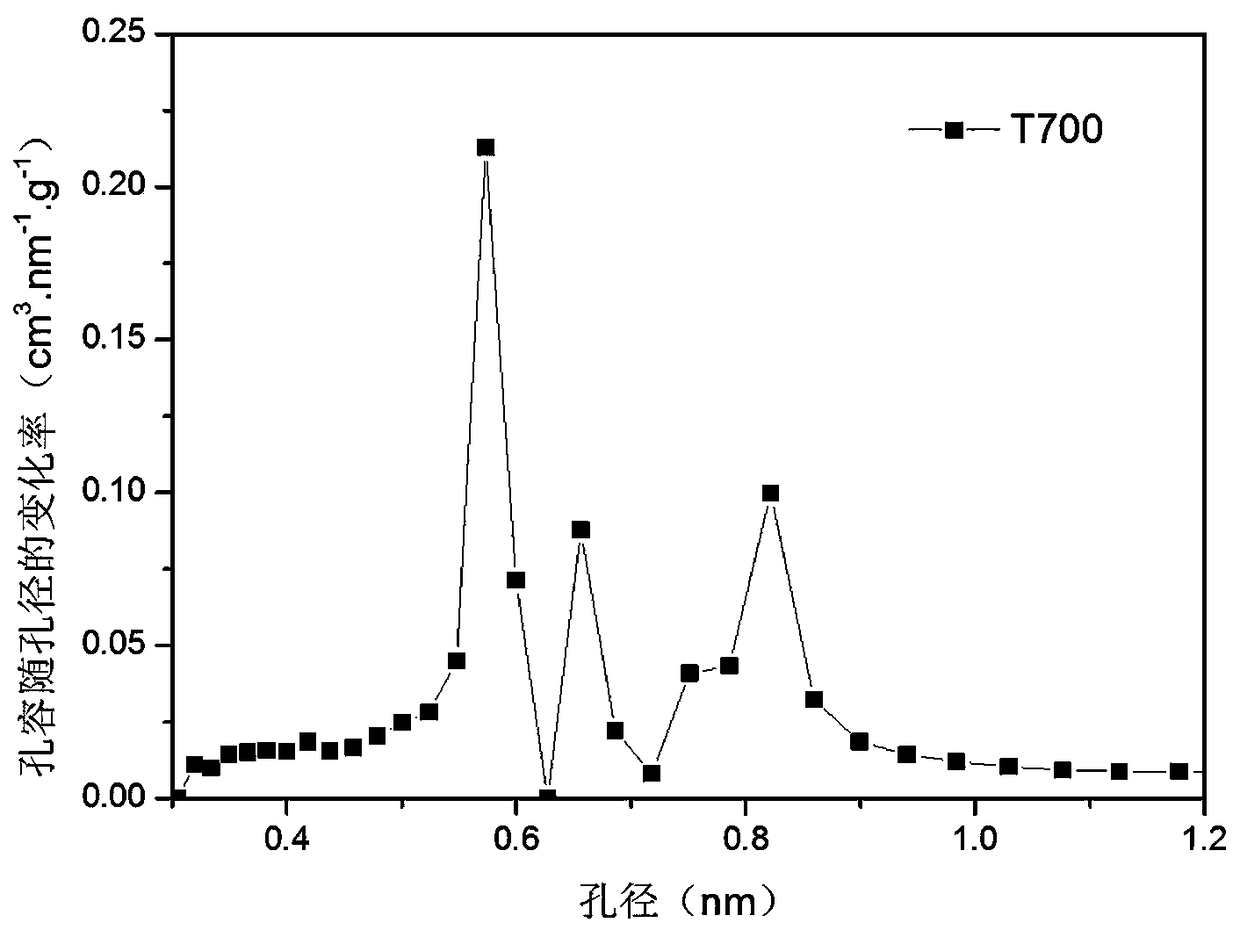

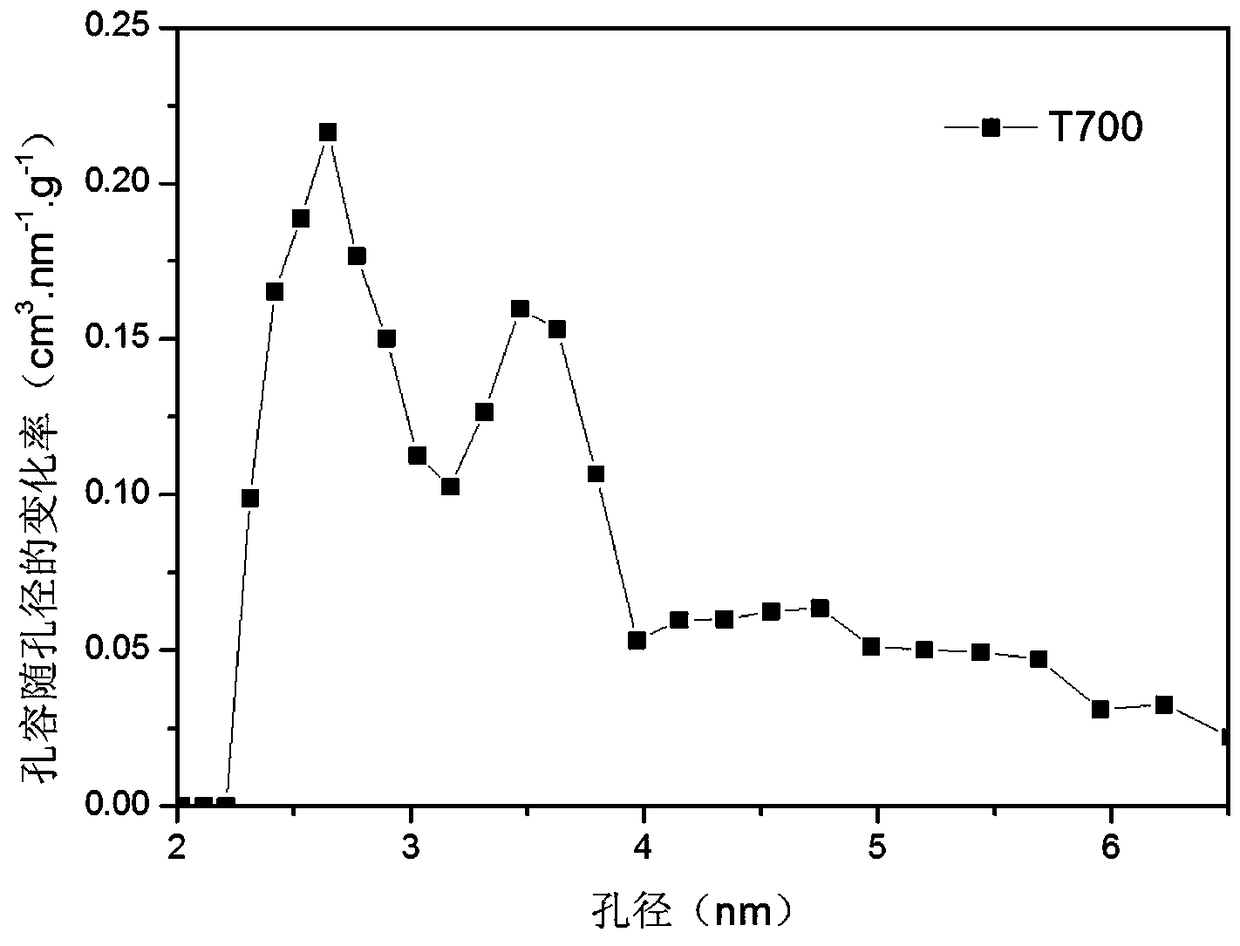

[0042] Adopt the NLDFT model to analyze the carbon adsorbent prepared in this embodiment under 273K CO 2 The adsorption isotherm was fitted to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com