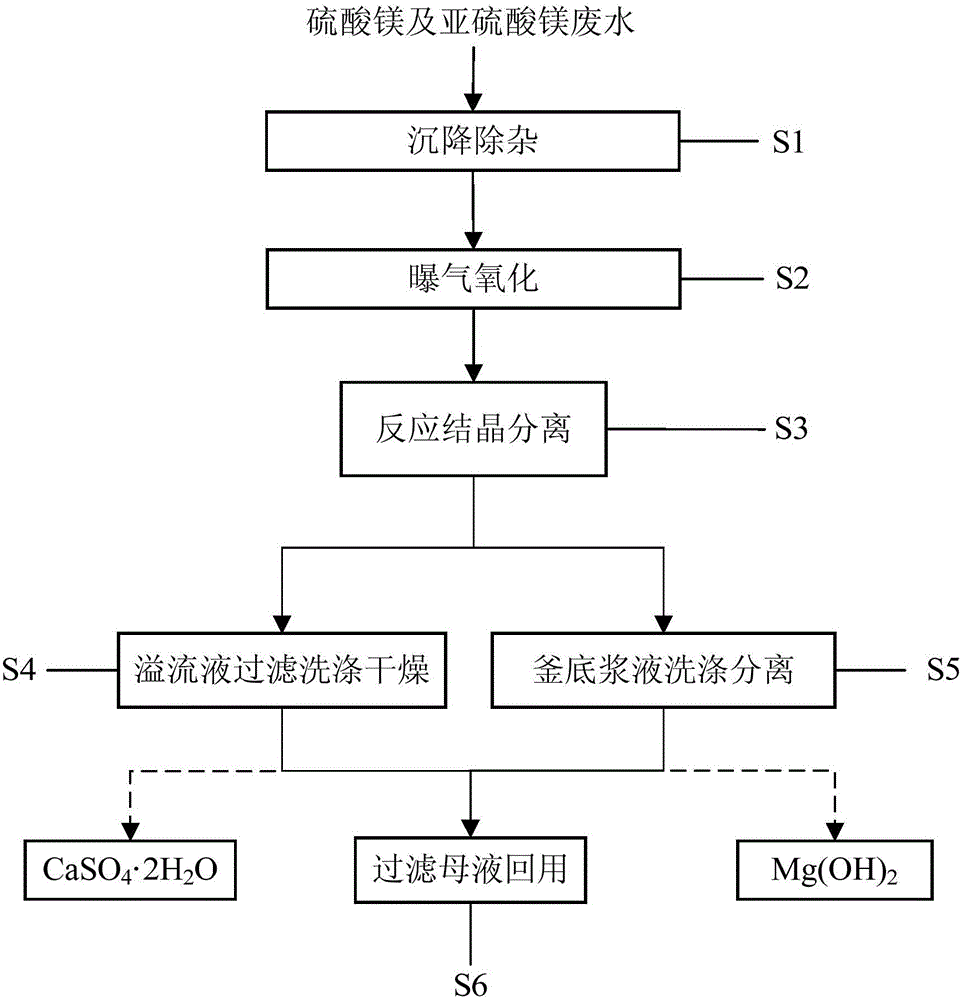

Method for treating magnesium sulfate and magnesium sulfite wastewater by virtue of lime method

A magnesium sulfite, magnesium sulfate technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate and other directions, can solve the problems of high energy consumption and high cost, achieve high separation efficiency, improve product purity, The effect of large separation coefficient of calcium and magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

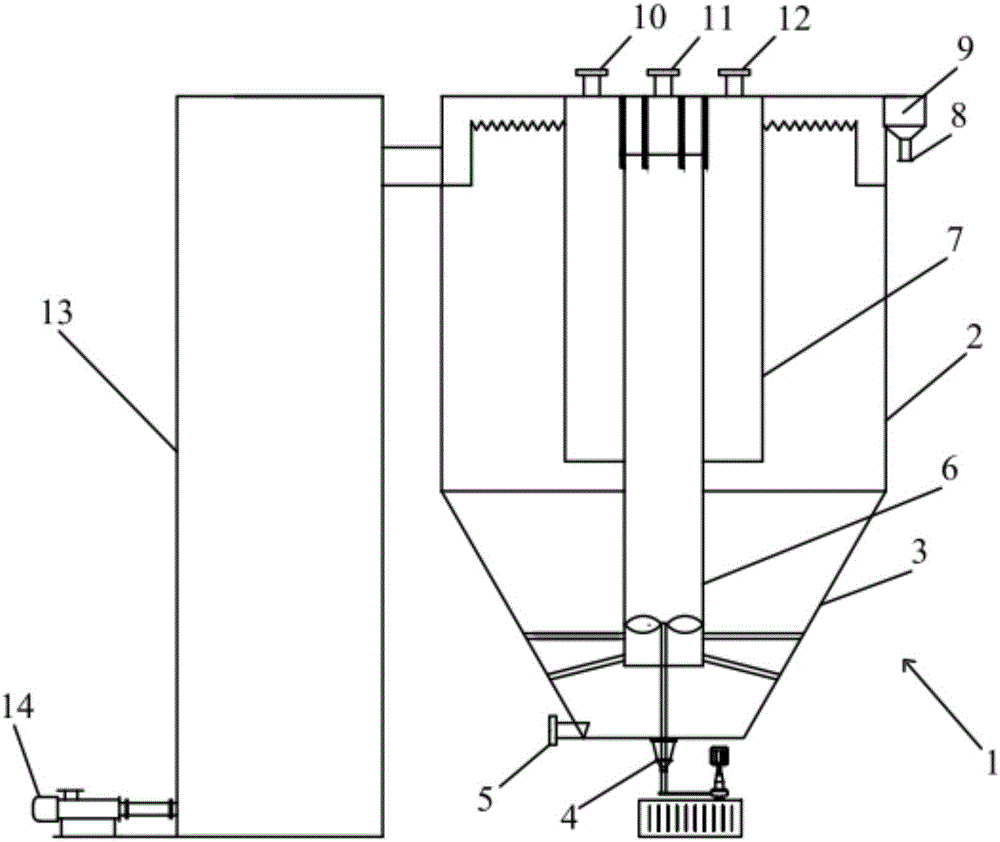

[0038] After the flue gas desulfurization of the power plant, the waste liquid is placed in a settler to settle to purify and remove insoluble matter. Pump the supernatant liquid of the settler into the filter for filtration, and analyze the composition after aeration treatment: Mg 2+ Content 2.04mol / L, SO 4 2- The content is 2.02mol / L; the lime slurry calcium hydroxide concentration is 1mol / L.

[0039] The above-mentioned purified magnesium sulfate waste liquid and lime slurry are continuously added to the reaction crystallizer from the wastewater inlet 11 and the lime slurry inlet 12 respectively, and the feed amounts of the purified magnesium sulfate waste liquid and lime slurry are adjusted to 2.4m respectively. 3 / h and 4.9m 3 / h. When the feed liquid level in the reaction crystallizer exceeds the upper mouth of the circulating lifting device 6, the circulating lifting device 6 is turned on, and the circulating liquid lifting flow rate of the circulating lifting device 6 is 8...

Embodiment 2

[0042] Take the magnesium sulfate type underground brine and place it in a settler to purify and remove insoluble matter. Pump the supernatant liquid of the settler into the filter and analyze the composition: Mg 2+ Content 0.21mol / L, SO 4 2- Content 0.16mol / L, Cl - Content 0.14mol / L, Ca 2+ The content is 0.02mol / L; the lime slurry calcium hydroxide concentration is 0.25mol / L.

[0043] The above-mentioned purified magnesium sulfate waste liquid and lime slurry are continuously added to the reaction crystallizer from the wastewater inlet 11 and the lime slurry inlet 12 respectively, and the feed amounts of the purified magnesium sulfate waste liquid and lime slurry are adjusted to 10.2m respectively. 3 / h and 8.0m 3 / h. When the feed liquid level in the reaction crystallizer exceeds the upper mouth of the circulating lifting device 6, the circulating lifting device 6 is turned on, and the circulating liquid lifting flow rate of the circulating lifting device 6 is 140m 3 / h, the ove...

Embodiment 3

[0046] Wastewater from a factory, main component: Mg 2+ Content 1.23mol / L, SO 3 2- Content 1.02mol / L, SO 4 2- The content is 0.20mol / L; the waste water is placed in a settler to settle, purify and remove insoluble matter. Pump the supernatant liquid of the settler into the filter for filtration, and configure the lime slurry with a calcium hydroxide concentration of 1.6 mol / L.

[0047] The above-mentioned purified magnesium sulfate waste liquid and lime slurry are continuously added to the reaction crystallizer from the waste water inlet 11 and the lime slurry inlet 12 respectively, and the feed amounts of the purified magnesium sulfate waste liquid and lime slurry are adjusted to 10m respectively. 3 / h and 6.8m 3 / h. When the feed liquid level in the reaction crystallizer exceeds the upper opening of the circulating lifting device 6, the circulating lifting device 6 is turned on, and the circulating liquid lifting flow rate of the circulating lifting device 6 is 160m 3 / h, the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com