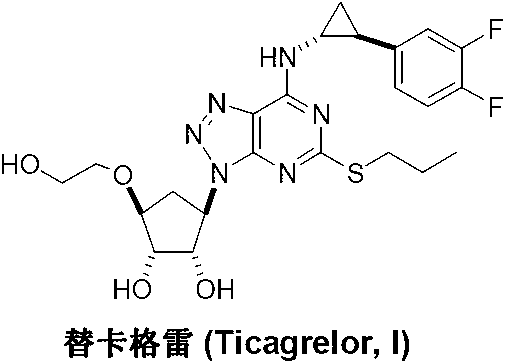

Preparation method of ticagrelor

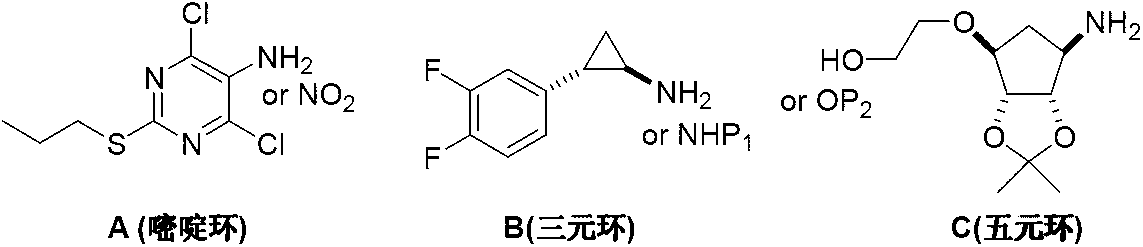

The technology of ticagrelor and amino group is applied in the field of preparation of new anticoagulant drug ticagrelor, which can solve the problems of difficult control of coupling position, and achieve the effects of high product yield and product purity, and quick and convenient preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

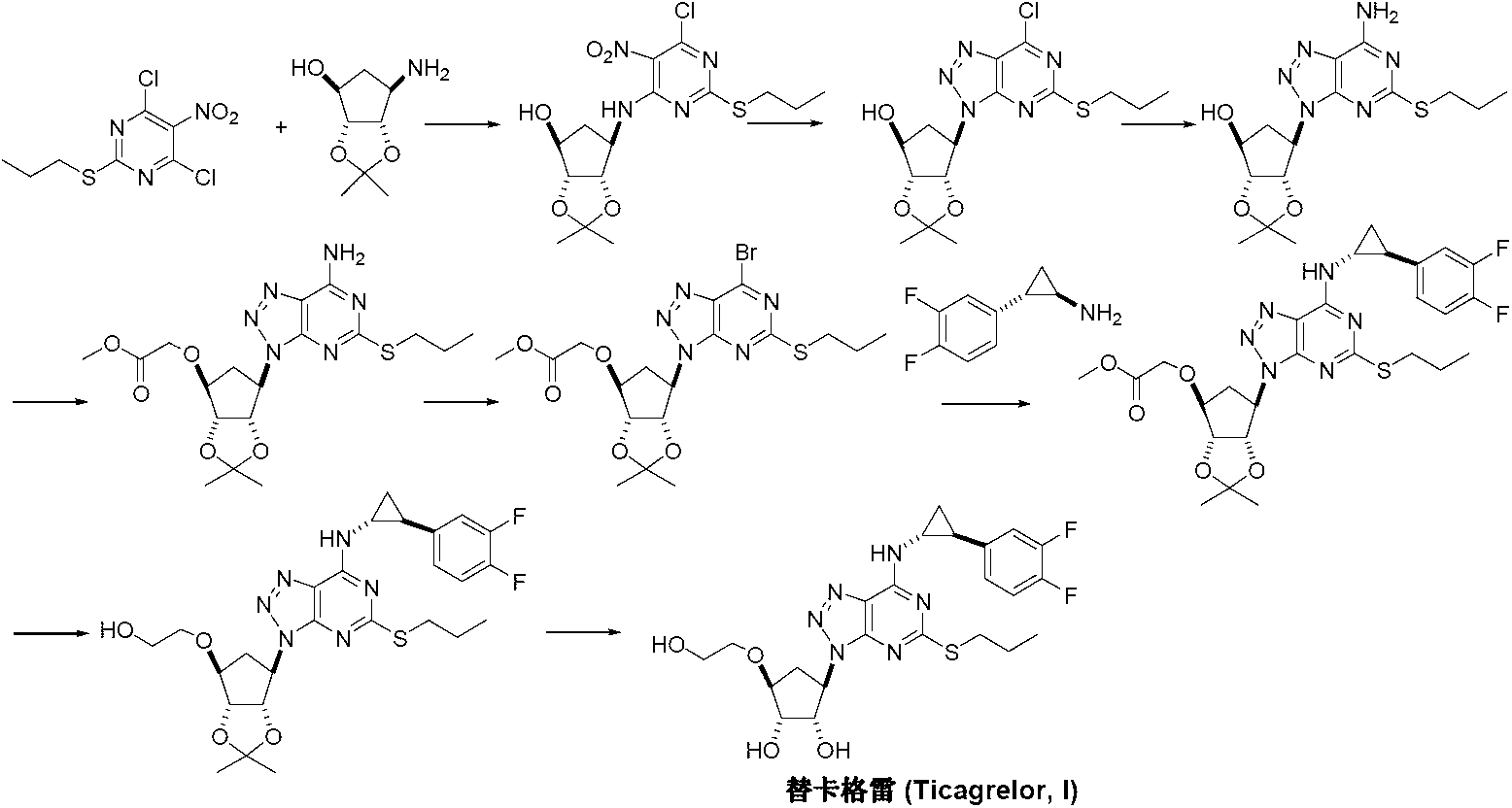

Method used

Image

Examples

Embodiment 1

[0040]Add 1-[3aR-(3aα, 4α, 6α, 6aα)-[[2,2-dimethyl-tetrahydro-4H-cyclopentadieno-1,3-dioxolane to the reaction flask -4-Oxy]ethanol]-6-yl]-5-amino-4-carboxamido-1,2,3-triazole (II) (3.27 g, 10 mmol), potassium carbonate (4.14 g, 30 mmol) ), 2 mL of water and 50 mL of dichloromethane. The temperature was lowered to 0° C., and a solution of carbon dichlorosulfide (III) (3.45 g, 30 mmol) in 25 mL of dichloromethane was slowly added dropwise, and the mixture was reacted for 2 hours. The reaction solution was poured into ice water to quench the reaction, and the organic phase was separated. The aqueous phase was extracted twice with dichloromethane, the organic phases were combined, dried, and the solvent was removed under reduced pressure. The product was recrystallized from ethyl acetate to obtain off-white solid 9-[3aR-(3aα,4α,6α,6aα)-[[2,2-dimethyl-tetrahydro-4H-cyclopentadieno-1 , 3-dioxolane-4-oxy]ethanol]-6-yl]-2-thio-6-oxo-8-azapurine (IV) 3.14g, yield 85.1%.

Embodiment 2

[0042] Add 9-[3aR-(3aα, 4α, 6α, 6aα)-[[2,2-dimethyl-tetrahydro-4H-cyclopentadieno-1,3-dioxolane to the reaction flask -4-Oxy]ethanol]-6-yl]-2-thio-6-oxo-8-azapurine (IV) (1.85 g, 5 mmol), potassium hydroxide solution (0.1 M, 10 mL) and To 25 mL of acetonitrile, a solution of bromopropane (V) (1.53 g, 12.5 mmol) in acetonitrile was added dropwise at room temperature. The reaction was stirred at room temperature for 15 hours. The solvent was recovered under reduced pressure, the residue was extracted three times with dichloromethane, the organic phases were combined, dried, and distilled under reduced pressure to obtain an oily substance 9-[3aR-(3aα, 4α, 6α, 6aα)-[[2,2-dimethylformaldehyde yl-tetrahydro-4H-cyclopentadieno-1,3-dioxolane-4-oxy]ethanol]-6-yl]-2-propylmercapto-6-oxo-8-aza Purine (VI) 1.83 g, yield 89.1%.

Embodiment 3

[0044] Add 9-[3aR-(3aα, 4α, 6α, 6aα)-[[2,2-dimethyl-tetrahydro-4H-cyclopentadieno-1,3-dioxolane to the reaction flask -4-Oxy]ethanol]-6-yl]-2-propylmercapto-6-oxo-8-azapurine (VI) (1.95g, 5mmol), phosphorus oxychloride 7.5mL, start stirring, cool down At 0°C, 3.5 mL of 2,6-lutidine was added dropwise. The temperature was slowly raised to 100°C, and the reaction was stirred at this temperature for 9 hours. Phosphorus oxychloride was recovered under reduced pressure, and after the residue was cooled to room temperature, the reaction was quenched with ice water. Extract three times with dichloromethane, combine the organic phases, dry over anhydrous sodium sulfate, recover the solvent under reduced pressure, dissolve the obtained oil in 25 mL of acetonitrile and transfer it to a reaction flask, add trans-(1R, 2S)-2-( 3,4-Difluorophenyl)cyclopropylamine (VII) (1.0 g, 6 mmol) and pyridine 1.5 mL. The reaction was stirred at room temperature for 12 hours, and the reaction was com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com