Method for separating zirconium from hafnium by using elution extraction method

A technology of zirconium and hafnium extraction and leaching, which is applied in the field of separation of zirconium and hafnium by extraction and leaching, which can solve the problems that the extraction process cannot be carried out, the problem of emulsification cannot be solved, and the corrosion of equipment and workshops, etc., and achieves easy operation, low consumption and high product quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare 2L mixed acid solution: add 0.168L concentrated hydrochloric acid (chemically pure, concentrated hydrochloric acid concentration is 12mol / L) to deionized water, then add 0.152 kg of ammonium thiocyanate, add deionized water to 2L, after each addition of substances Stir evenly, and measure the total free acid acidity of the saturated acid solution to be 1.0mol / L.

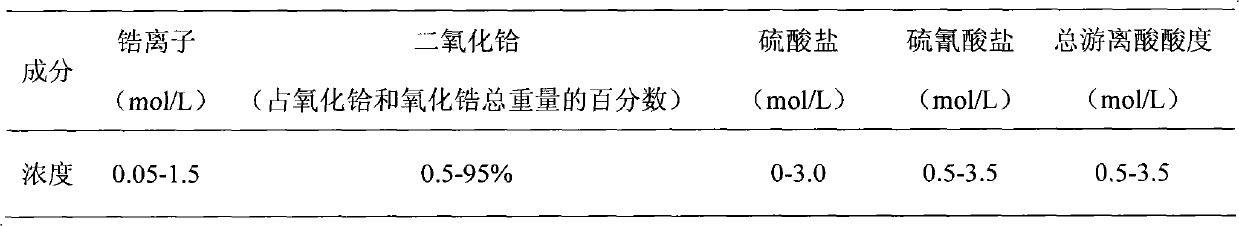

[0034] Prepare 4L feed liquid: Weigh 1.66 kg of industrial grade zirconium oxychloride, 0.86 kg of ammonium thiocyanate and 0.248 kg of ammonium sulfate, stir and dissolve in 2L of deionized water, filter after dissolving, and add deionized water To 4L, the total concentration of zirconium ion and hafnium ion is 1.17mol / L, the content of hafnium dioxide accounts for 2.07% of the total weight of hafnium dioxide and zirconium dioxide, and the total free acid acidity of described feed liquid is 1.0mol / L ( The acidity here is because the zirconium oxychloride raw material is crystallized from a 6.0mol / L hy...

Embodiment 2

[0048] Prepare 2L mixed acid solution: add concentrated hydrochloric acid (chemically pure, concentration of concentrated hydrochloric acid is 12mol / L) and ammonium thiocyanate in deionized water, wherein the concentration ratio of hydrochloric acid and ammonium thiocyanate is 1:1, add deionized water to 2L, stir evenly, and measure the total free acid acidity of the saturated acid solution to be 1.0mol / L.

[0049] Prepare 2L feed liquid: Weigh 0.415 kg of industrial grade zirconium oxychloride, 0.294 kg of ammonium thiocyanate and 0.085 kg of ammonium sulfate, stir and dissolve in 1L of deionized water, filter after dissolving, add 12mol / L of Concentrated hydrochloric acid 0.066L, add water to 2L, the total concentration that obtains zirconium ion and hafnium ion in the material liquid is 0.58mol / L, the content of hafnium dioxide accounts for 2.04% of hafnium dioxide and zirconium dioxide gross weight, described material The total free acidity of the liquid is 1.0mol / L, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com