Inner and outer surface dyeing device for full absorption of garment cloth

A fully absorbing and dyeing device technology, applied in the field of garment processing, can solve the problems of affecting the dyeing quality of fabrics, the inability to absorb dyes uniformly and fully, and the quality of fabrics being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

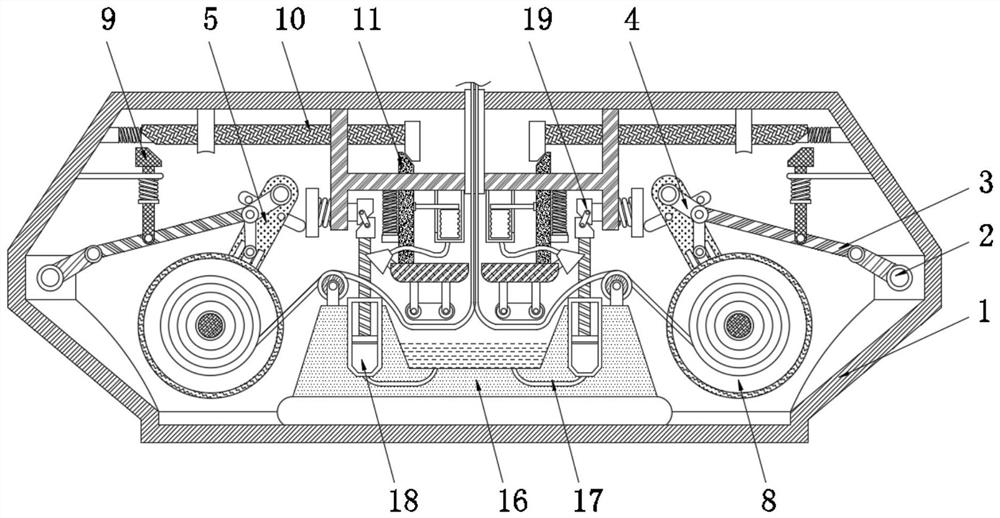

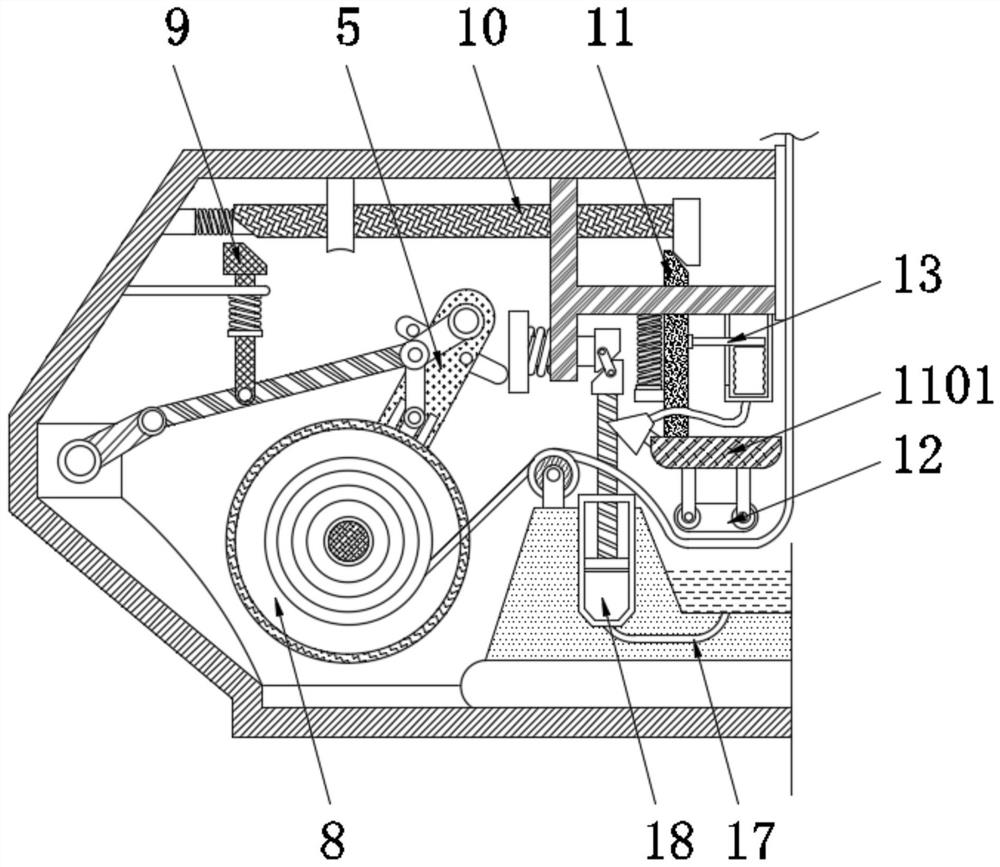

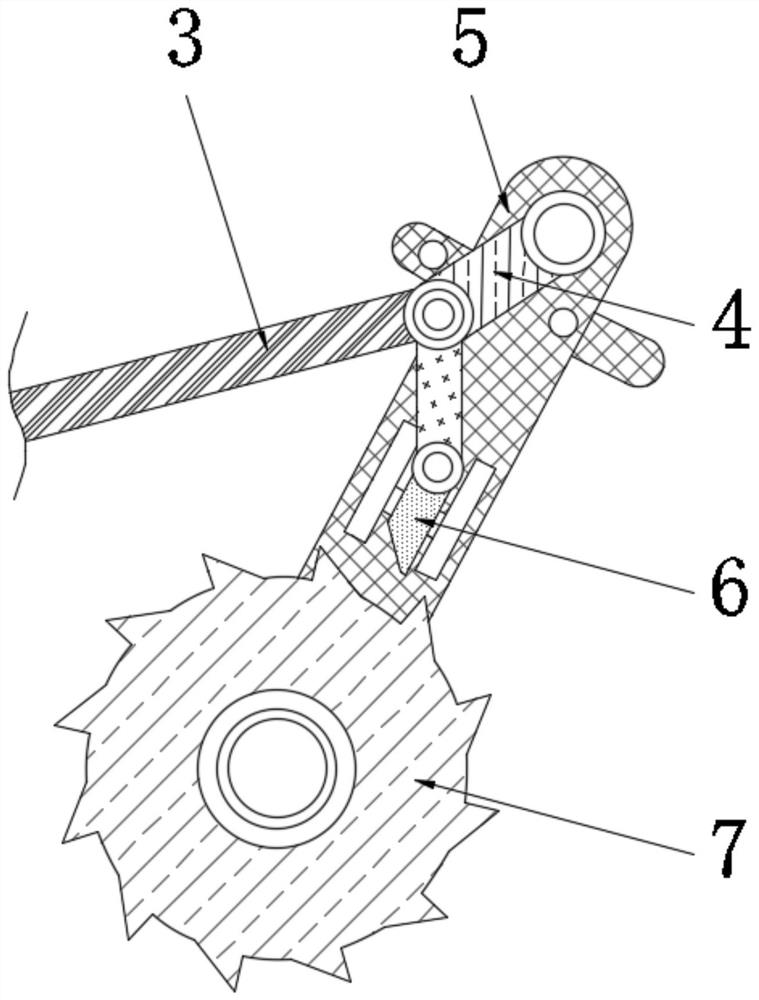

[0020] The invention provides an inner and outer surface dyeing device for fully absorbing clothing fabrics, as attached figure 1 to attach Figure 4 Shown: including the dyeing chamber 1, the internal rotation of the dyeing chamber 1 is installed with the rotating plate 2, the rotating plate 2 is fixedly connected with the drive shaft, the end of the rotating plate 2 is equipped with a movable rod 3, and the end of the movable rod 3 is movable There is a hinged rod 4, the top of the hinged rod 4 is movably installed with a swing plate 5, and the bottom end of the hinged rod 4 is movably connected with a block 6, the block 6 is slidably installed on the front surface of the swing plate 5, and the swing plate 5 is socketed on the The outer surface of the engaging plate 7, the hinged rod 4 is composed of adjacent connecting rods, the left and right sides of the hinged rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com