A biofilm waste gas treatment equipment

A technology for waste gas treatment equipment and biofilm, which is applied in air quality improvement, separation method, and dispersed particle separation, etc., can solve the problems of increasing the cost of the absorption packed tower, easy blockage of the lower packing, and poor absorption effect, and achieves less blockage. , The absorption is even and sufficient, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

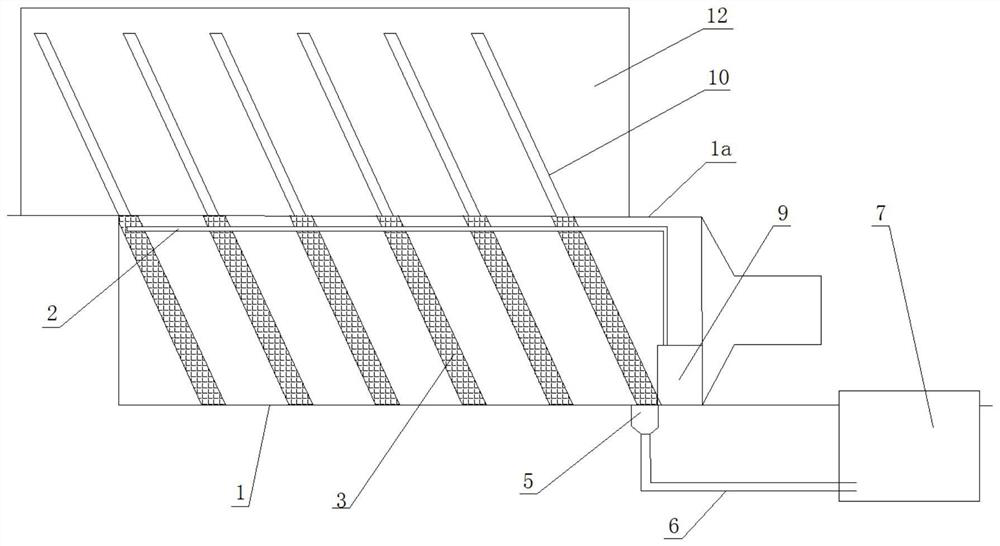

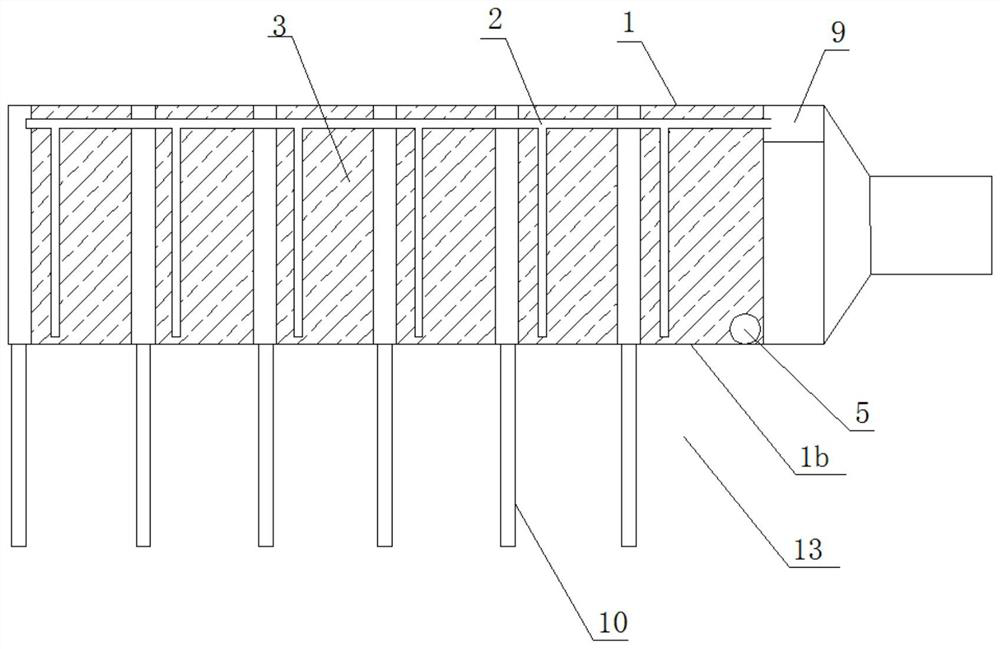

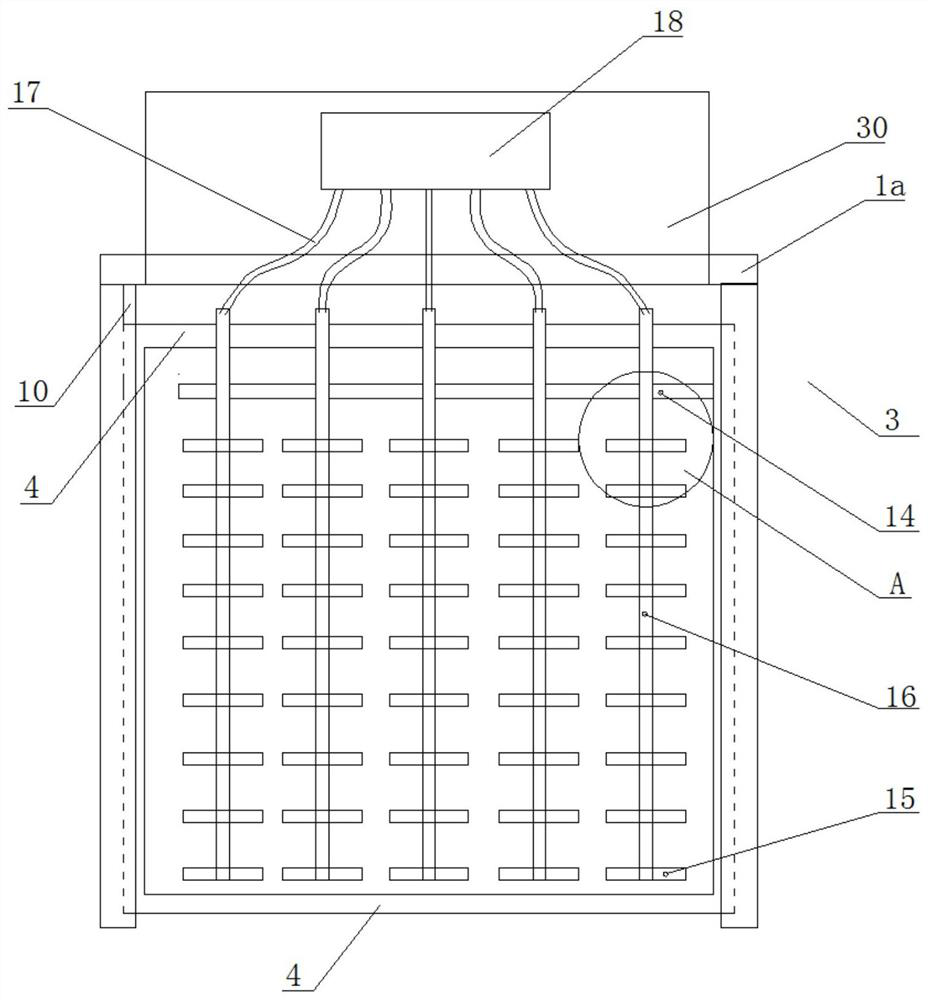

[0034] like figure 1 and figure 2 As shown, the biofilm waste gas treatment equipment of the present invention includes a box body 1, a waste gas channel arranged on the box body 1, a spray system 2 and a control device arranged on the upper part of the box body 1, and the box body 1 includes a side wall 1b, bottom plate and top cover 1a, a plurality of biofilm filler plates 3 are arranged in the box 1, preferably six biofilm filler plates 3 are arranged, and each biofilm filler plate 3 includes a frame 4 and is installed on the frame 4 The packing device 8, the exhaust gas channel is arranged laterally. The spray system 2 is connected to the control device, the control device is the electric control cabinet 9, the bottom of the rear end of the box 1 is provided with a sludge discharge port 5, the sludge discharge port 5 is connected to the sludge discharge pipe 6, and the sludge discharge pipe 6 is connected to the activated sludge Pool 7.

[0035] The exhaust gas channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com