Colored paper making and coloring equipment and method

A technology for making paper and paper, which is applied to colored paper making and coloring equipment and fields, to achieve the effects of cost reduction, water saving, and uniform coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

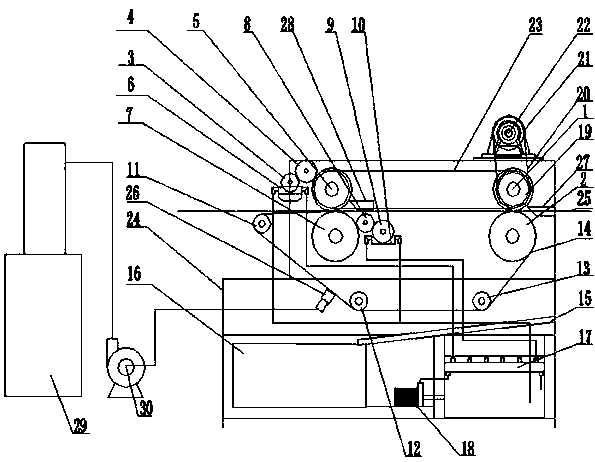

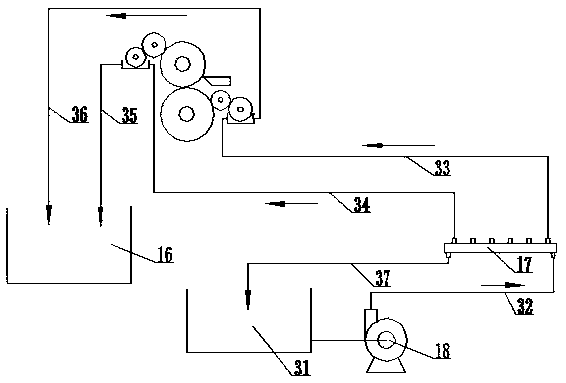

[0036] refer to Figure 1-Figure 2 , the colored paper papermaking and coloring equipment of the present embodiment, comprising a frame 24, a water squeezing main rotating smooth roller 1, a water squeezing rubber roller 2, an upper coloring smooth roller 3, an upper coloring rubber roller 4, and an upper coloring rotating smooth roller 5. Upper dye tank 6, lower coloring rotating rubber roller 7, lower coloring light roller 8, lower coloring rubber roller 9, lower dye tank 10, adjustable tension roller 11, fixed tension roller, transmission blanket 14, power Device, dye recovery tank 15, dye recovery storage tank 16, dye delivery distribution table 17, dye delivery pump 18, dye storage tank 31, dye delivery pipe 32, lower coloring dye delivery pipe 33, upper coloring dye delivery pipe 34, The upper dye recovery pipe 35 and the lower dye recovery pipe 36;

[0037] The water squeezing main rotating smooth roller 1 is installed on the frame 24 through the bearings and bearing s...

Embodiment 2

[0064] The colored paper papermaking and coloring equipment of this embodiment differs from that of Embodiment 1 in that: the lower coloring smooth roller 8, the lower coloring rubber roller 9, the lower dye tank 10, the lower coloring dye conveying pipe 33 and the lower dye recovery Tube 36.

[0065] The coloring method can refer to Embodiment 1, and will not be repeated here.

Embodiment 3

[0067] The colored paper papermaking and coloring equipment of this embodiment differs from that of Embodiment 1 in that the upper coloring smooth roller 3, the upper coloring rubber roller 4, the upper dye tank 6, the upper coloring dye conveying pipe 34 and the upper dye recovery are omitted. Tube 35.

[0068] The coloring method can refer to Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com