Intelligent horizontal spray-dyeing device and use method thereof

An equipment, horizontal technology, applied in the field of intelligent horizontal jet dyeing equipment, can solve the problems of waste of dye costs, increase the difficulty and cost of papermaking and dyeing wastewater treatment, increase the number of reuses, reduce the cost of sewage treatment, The effect of water consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

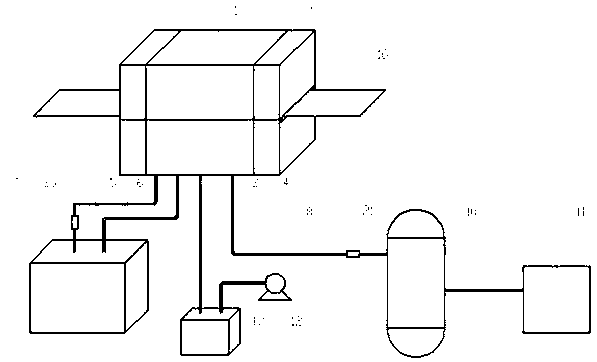

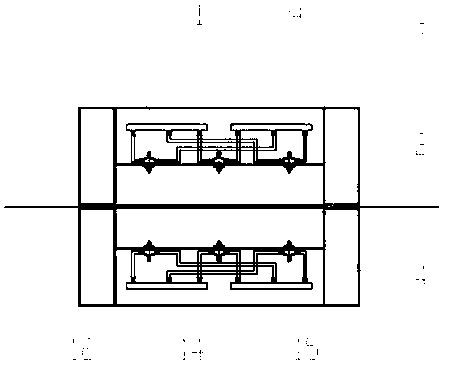

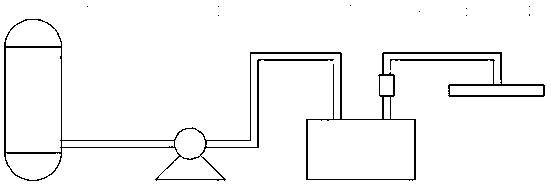

[0023] In this embodiment, an intelligent horizontal spray-dyeing equipment and its auxiliary system are used to uniformly color the paper in the papermaking production line to produce brightly colored colored paper. The present invention is achieved in the following way: an intelligent horizontal spray dyeing equipment unit, comprising upper and lower spray dyeing boxes (1, 2); upper and lower negative pressure gas-liquid recovery boxes (3, 4); dye supply pipelines (5); Dye recovery pipeline (6); Dye material tank (7); Compressed air supply pipeline (8); Nozzle (9); Air storage tank (10); Air compressor (11); Negative pressure vacuum pump (12 ); gas-liquid separator (13); gas distribution device (14); liquid distribution device (15). In order to ensure the stable supply of dye, it is necessary to configure a material tank, which is connected to the liquid distribution device through the dye supply pipeline, and is delivered to each nozzle through the liquid distribution devic...

Embodiment 2

[0032] This embodiment introduces the practical application of applying the device to the printing and dyeing of red paper.

[0033] Add the red dye into the dispensing tank together with water in a certain proportion according to the process requirements. After stirring evenly, put the mixed dye into the storage tank through the booster pump for standby. After the equipment is started, the system detects the pressure of the compressed air in the storage tank and whether the liquid level of the dye tank meets the requirements. If it does not meet the requirements, the PLC will automatically control the start of the air compressor or the feeding of the automatic feeding system. When the spray-dyeing processing conditions are met, the soaked paper will slowly enter the intelligent horizontal spray-dyeing equipment driven by the transmission system. The compressed air control valve automatically opens a certain opening (can be set on the PLC control interface according to the pro...

Embodiment 3

[0035] This example introduces the practical application of applying the device to the printing and dyeing of blue cotton cloth.

[0036] Add the blue dye into the dispensing tank together with water in a certain proportion according to the process requirements. After stirring evenly, put the mixed dye into the storage tank through the booster pump for standby. Whether the pressure and the liquid level of the dye tank meet the requirements, if not, the PLC automatically controls the start of the air compressor or the automatic feeding system to feed. When the spray-dyeing processing conditions are met, the soaked cotton cloth slowly enters the intelligent horizontal spray-dyeing equipment driven by the transmission system. The compressed air control valve automatically opens a certain opening (can be set on the PLC control interface according to the process needs), the nozzle starts to spray air, and at the same time the dye is automatically sucked into the nozzle through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com