Dyeing residual liquid recycling and dye recovery processing method, and special dyeing residual liquid processing pool

A technology for dyeing residue and recycling, applied in dyeing methods, chemical instruments and methods, water/sewage treatment, etc. Biochemical, COD and chroma reduction, dye saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

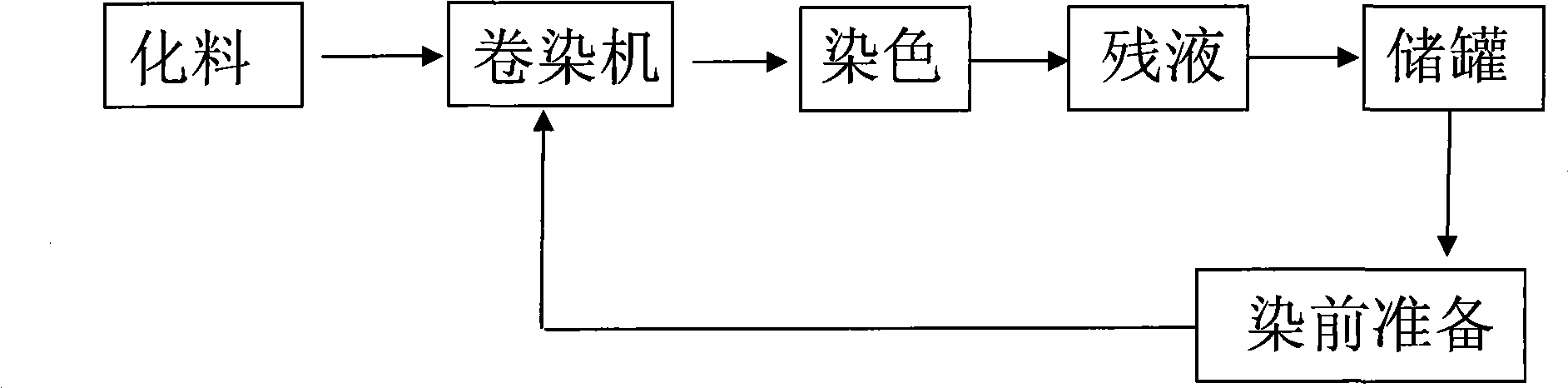

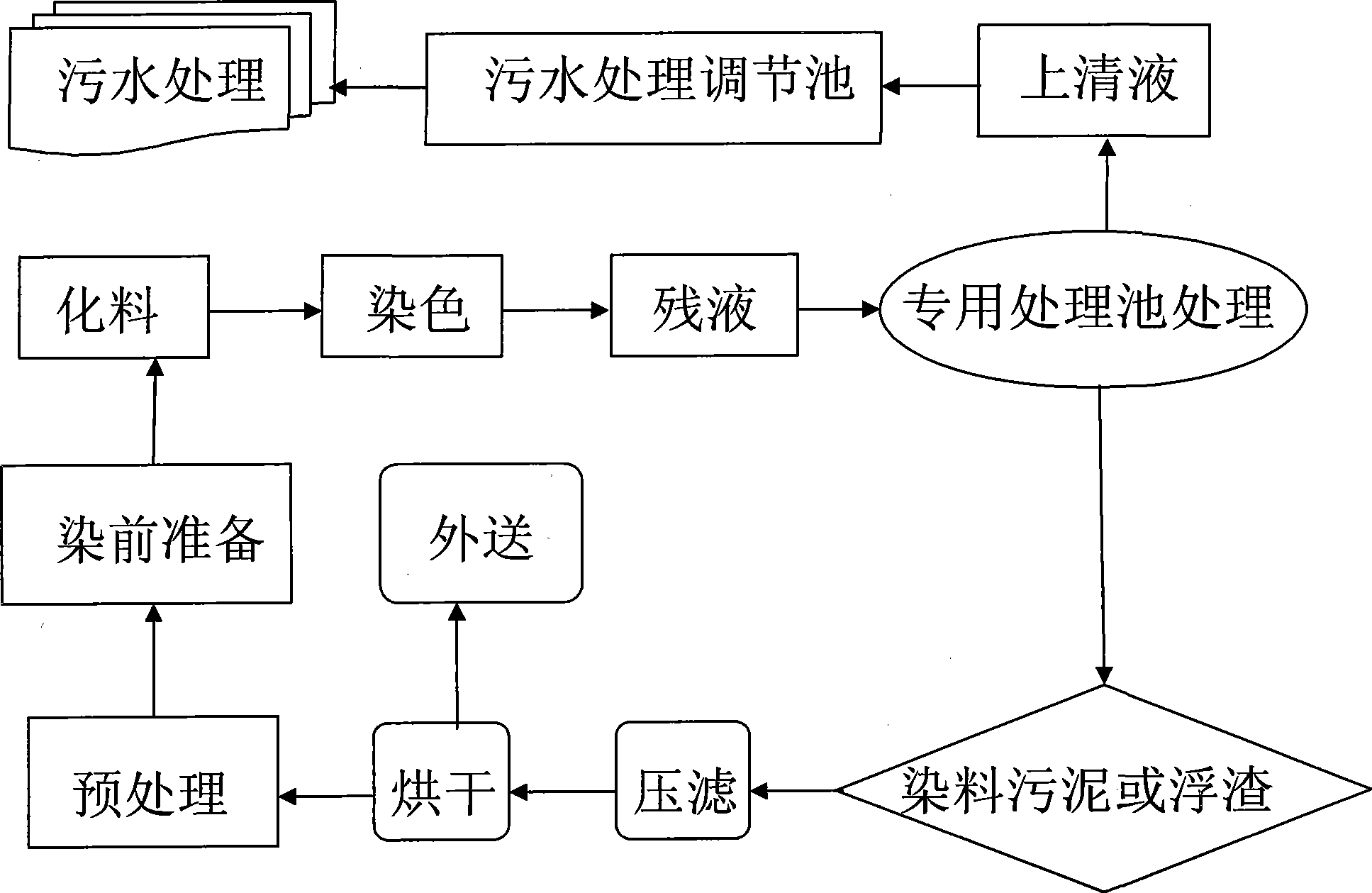

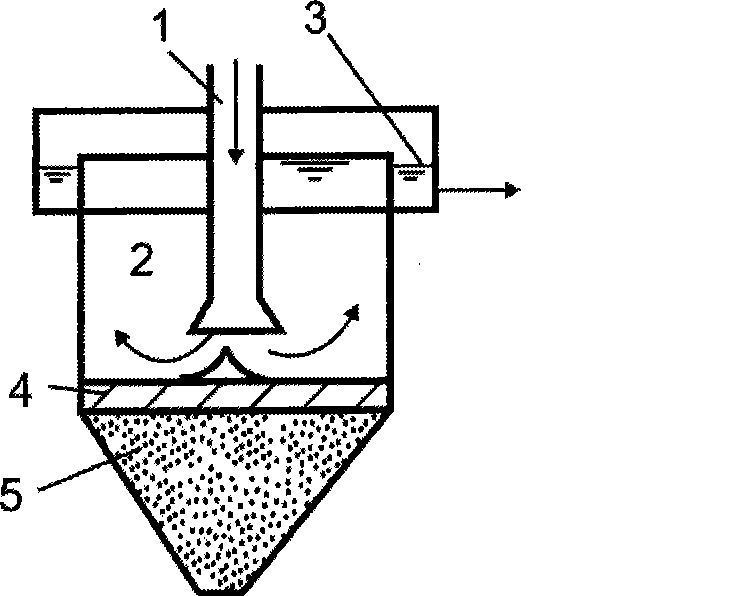

Embodiment 1

[0052] A method for recycling dyeing residue and recovering dyes, wherein the dyes are acid dyes and direct dyes. Among the five dyeing methods of jigger dyeing, pad dyeing, overflow, skein, and cone yarn, pad dyeing is a continuous process. Although the amount of residual liquid is small, the concentration of dyeing residual liquid is the highest, and there is no problem of reuse of continuous cylinders. The greatest impact; the amount of overflow dyeing residue is the largest, up to 1.5-2.5 tons per cylinder. It is difficult to store, and it is usually no longer considered to reuse the cylinder. Therefore, the reuse of refill cylinders is generally used in jigger, hank and bobbin processes. For some orders with many kinds of colors, when arranging the production plan, the same batch of products should master the principle of light to dark, first process the light color, and then process the dark color; when each color is produced, the dyeing residue can be continued. Cylin...

Embodiment 2

[0072] A dyeing residue recycling and dye recovery treatment method, the dyes are vat dyes or sulfur dyes, the dye recovery method in the dyeing residue and the structure of the special treatment pool for the dyeing residue are the same as in Example 1. The recycling process of dyeing residual liquid in continuous cylinder is roughly the same as that in Example 1. The specific process steps of the reuse of the residual dyeing liquid in the tank are as follows:

[0073] 1. Make the concentration-absorbance working curve of the basic dye

[0074] (1) Standard series with basic dye concentration

[0075] The basic dyes selected in production, such as vat yellow G, vat RB black, vat olive green T, vat olive green B, vat BR brown, vulcanized RDT-R brown, vulcanized RDT-E yellow, vulcanized RDT-D black, vulcanized RDT-2G Blue, sulfur RDT-GSL brown and other basic dyes are respectively configured into a series of dilute solutions with concentrations. Generally, each dye has 5-6 con...

Embodiment 3

[0085] A dyeing residue recycling and dye recovery treatment method, the dye is a reactive dye, the dye recovery method in the dyeing residue and the structure of the special treatment pool for the dyeing residue are the same as in Example 1, and the dyeing residue The recycling process of the continued cylinder is roughly the same as that in Embodiment 1. The specific process steps of the reuse of the residual dyeing liquid in the tank are as follows:

[0086] 1. Make the concentration-absorbance working curve of the basic dye

[0087] The different colors on the fabric are mainly formed by mixing the three primary colors of red, yellow and blue in different proportions. But red has bright red (yellow light red) and rose red (blue light red), yellow has green light yellow (bright yellow) and red light yellow, and blue has bright blue, dark blue and emerald blue. Therefore, the first step in reusing dyeing residual liquid is to make working curves for eight dyes of yellow li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com