Linen fabric dyeing device

A dyeing device and linen technology, which is applied in the processing of textile material equipment configuration, textile material processing, liquid/gas/steam textile material processing, etc., can solve the problems of cumbersome dip-dyeing operations and the need to improve dyeing efficiency, and achieve heat reduction Loss, reduce dyeing cost, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The present invention is further illustrated by the accompanying drawings and specific examples of the specification.

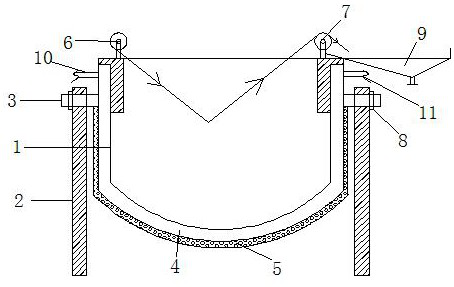

[0019]Seefigure 1A linen material staining device comprising a dipping bucket 1 and a dipping tub holder 2, and the soaking bucket 1 is connected between the shaft pin 3 and the bolt 8, and one layer of heating in the outer wall of the soaking bucket 1 Vennel 4, the top symmetry of the solenoid tank 1 is provided with a linen press roller bracket 6 and a linen guide roller holder 7, and a dye recovery apparatus 9 is attached below the linen guide roller holder 7.

[0020]As a preferred embodiment, the heating medium inlet 10 and the heating medium outlet 11 are provided in this embodiment, the heating medium inlet 10 and the heating medium outlet 11 are located at the upper end of the heating chamber 4, and the heating in the present embodiment The medium is steam.

[0021]As a preferred embodiment, there is a layer of insulation layer 5 on the outer wall of the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com