Cloth dyeing machine

A cloth dyeing machine and cloth dyeing technology, applied in the field of cloth dyeing machines, can solve the problems of dyeing liquid pollution, low utilization rate of dyeing liquid, uneven dyeing, etc., and achieve the effect of reducing waste and pollution, improving printing and dyeing effect, and fully uniform printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

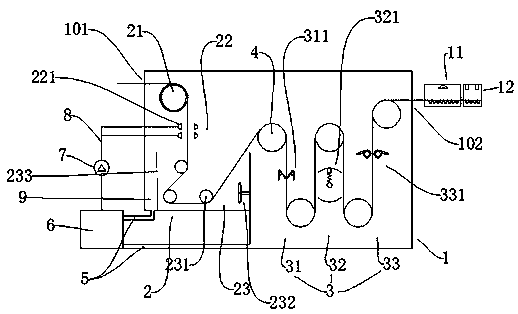

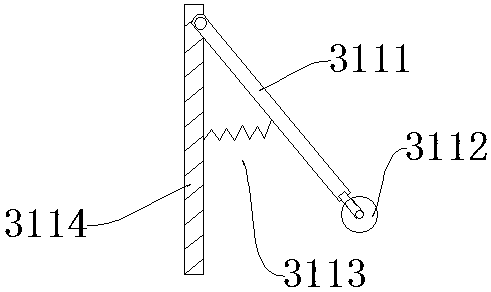

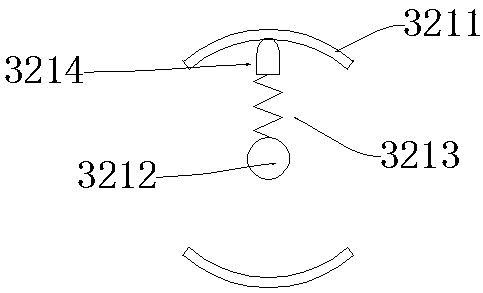

[0034]A cloth dyeing machine, comprising a cloth dyeing box 1, the cloth dyeing box 1 includes a printing and dyeing area 2 provided with a cloth inlet 101 and a functional area 3 provided with a cloth outlet 102, the printing and dyeing area 1 is provided with a The unwinding roller 21 at the entrance 101, the spraying structure 22 located below the unwinding roller 21 and the printing and dyeing tank 23 located below the spraying structure 22, the spraying structure 22 is arranged symmetrically on both sides of the cloth. The spray head 221 on the side, the spray direction of the spray head 221 is perpendicular to the moving direction of the cloth, the printing and dyeing tank 23 is provided with a number of printing and dyeing rollers 231 and agitators 232 that provide tension, one side of the printing and dyeing tank 23 The tank wall is provided with an overflow port 233, and the overflow port 233 is connected to the dyeing liquid recovery pipeline 5 through the overflow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com