Printing and dyeing production process and device for all-cotton antibacterial double-sided cloth

A production device and production process technology, applied in the processing of textile materials, continuous processing of textile materials, equipment configuration for processing textile materials, etc., can solve problems such as high defect rate of printed and dyed fabrics, product manufacturing defects, and low printing and dyeing efficiency. Achieve the effect of improving printing and dyeing efficiency, improving printing and dyeing effect, and high printing and dyeing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

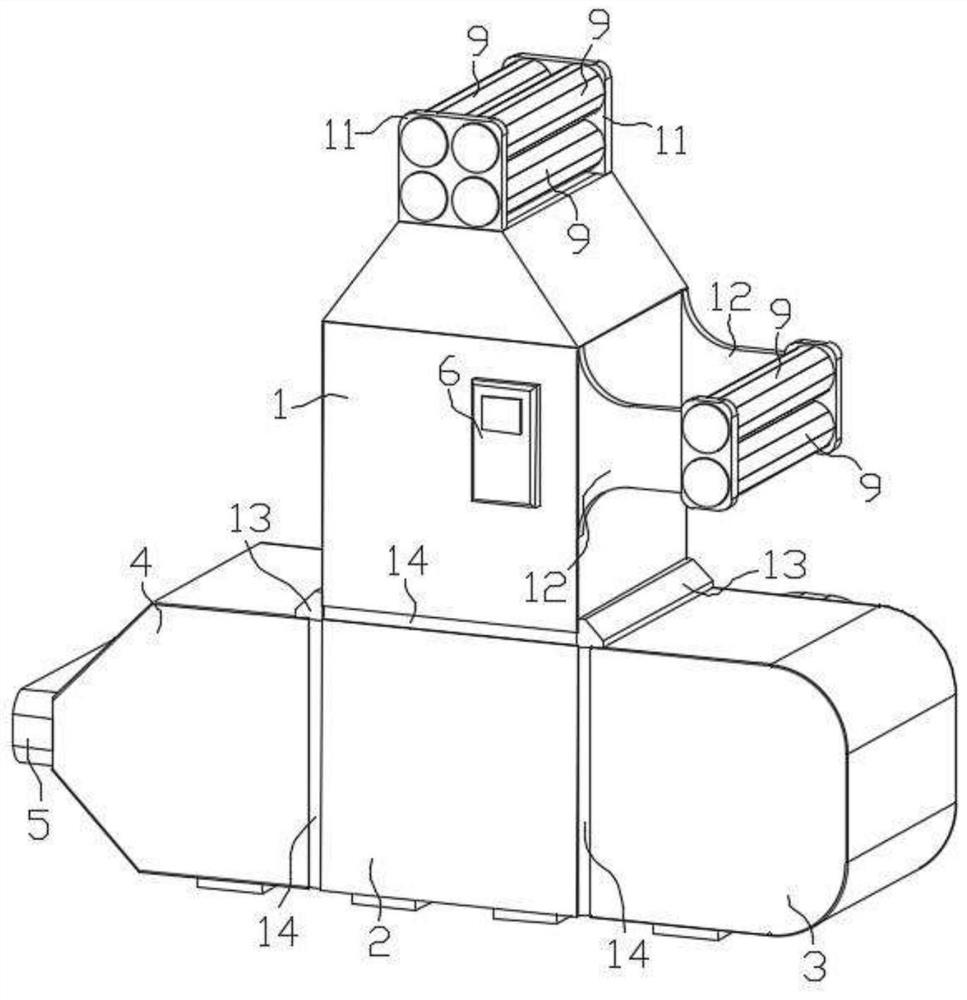

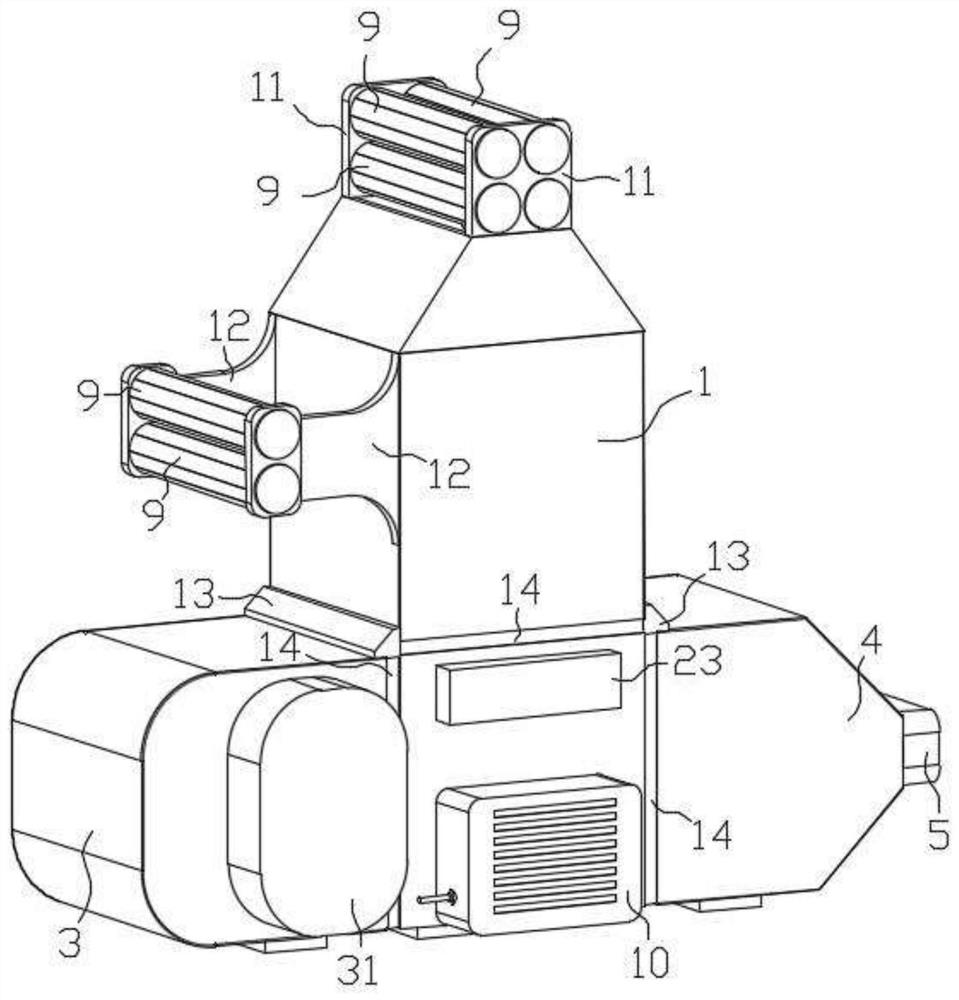

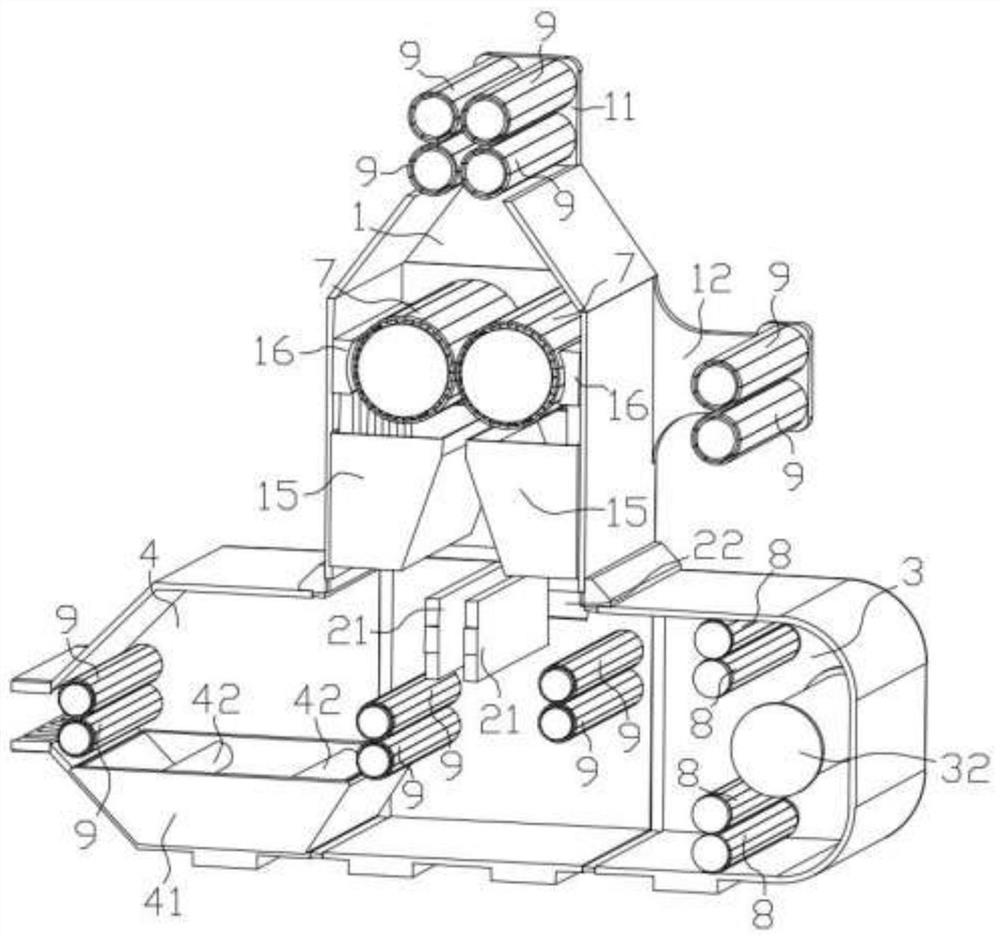

[0052] A printing and dyeing production process and a production device for an all-cotton antibacterial double-sided fabric, comprising the following steps:

[0053] S1: configure the dye color paste, the dye color paste is calculated in parts by mass: 12 parts of reactive dyes, 75 parts of printing paste, 4 parts of silicon steel powder and 4 parts of sodium m-nitrobenzene sulfonate, and then put the dye color paste in Place in the dye magnetization chamber 15, during which a stirring bar is used to stir for 35 seconds at intervals of 1.2 minutes, wherein the magnetic strength of the magnetic layer on the inner wall of the dye magnetization chamber 15 is 8000 gauss, and the magnetized dye color paste is obtained, which is ready for use;

[0054] S2: Use the production device and the magnetized dye paste obtained in step S1 to perform double-sided color printing on the cotton antibacterial double-sided fabric and then dry it;

[0055] S3: Steam the cotton antibacterial double-...

Embodiment 2

[0077] This embodiment is basically the same as Embodiment 1, except that the magnetization treatment parameters in step S1 and the ratio of slurry and color paste are different, as follows:

[0078] S1: Configure the dye color paste, the dye color paste is calculated in parts by mass: 10 parts of reactive dyes, 50 parts of printing paste, 3 parts of silicon steel powder and 2 parts of sodium m-nitrobenzenesulfonate, and then the dye color paste Place it in the dye magnetization chamber 15, and use a stirring rod to stir for 30 seconds at intervals of 1 min during this period, wherein the magnetic strength of the magnetic layer on the inner wall of the dye magnetization chamber 15 is 8000 gauss, and obtain a magnetized dye paste for use;

Embodiment 3

[0080] This embodiment is basically the same as Embodiment 1, except that the magnetization treatment parameters in step S1 and the ratio of slurry and color paste are different, as follows:

[0081] S1: Configure the dye color paste, the dye color paste is calculated in parts by mass: 15 parts of reactive dyes, 80 parts of printing paste, 5 parts of silicon steel powder and 5 parts of sodium m-nitrobenzenesulfonate, and then the dye color paste Place in the dye magnetization chamber (15) for placement, during which a stirring rod is used to stir for 40 s at intervals of 1.5 minutes, wherein the magnetic strength of the magnetic layer on the inner wall of the dye magnetization chamber 15 is 8000 gauss to obtain a magnetized dye paste for use;

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com