Nanofiltration membrane, and preparation method and application thereof

A nanofiltration membrane and reaction technology, applied in the field of composite membranes, can solve the problems of increasing wastewater treatment costs, limiting the dye separation process of polyamide composite nanofiltration membranes, poor chemical and physical stability of polyamide membranes, etc. Improved hydrophilicity and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

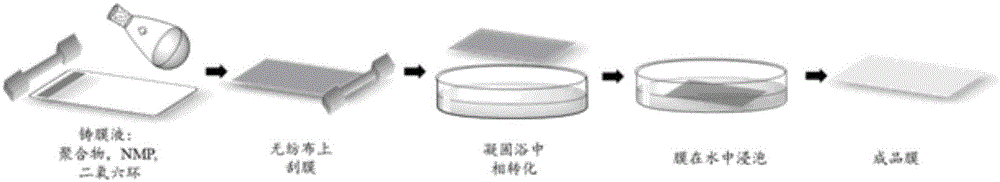

[0026] The embodiment of the present invention discloses a preparation method of a nanofiltration membrane, comprising the following steps:

[0027] A), mixing the polymer with a solvent and a co-solvent to obtain a polymer solution;

[0028] B), pouring the polymer solution onto the surface of the support, scraping the membrane, and performing phase inversion of the obtained nascent membrane in the coagulation bath aqueous solution to obtain a nanofiltration membrane;

[0029] The polymer is obtained by reacting an organic halide with phenolphthalein; the organic halide is selected from one or both of dichlorodiphenyl sulfone and difluorobenzophenone, or tetrafluorodiphenyl sulfone.

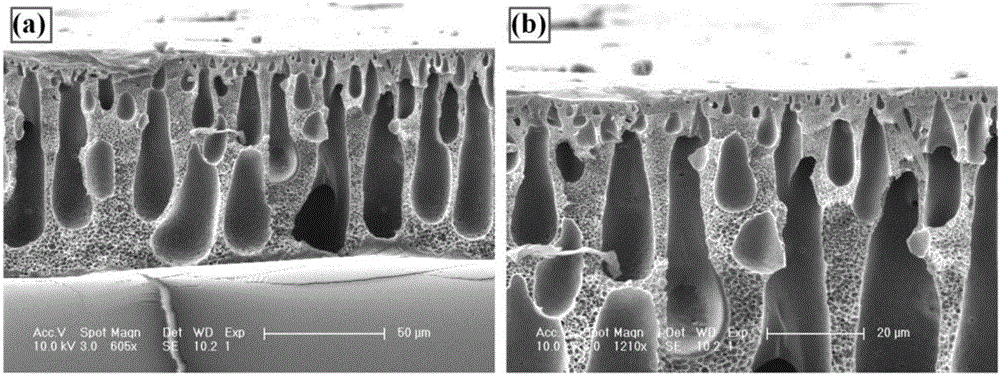

[0030] This application uses polyarylethersulfone (PAES-COOH, FPAES-COOH) or polyaryletherketone (PAEK-COOH) containing carboxyl groups as raw materials, and uses a non-solvent-induced phase inversion method to prepare a nanofiltration membrane. The filter membrane has good hydrophilicity and t...

Embodiment 1

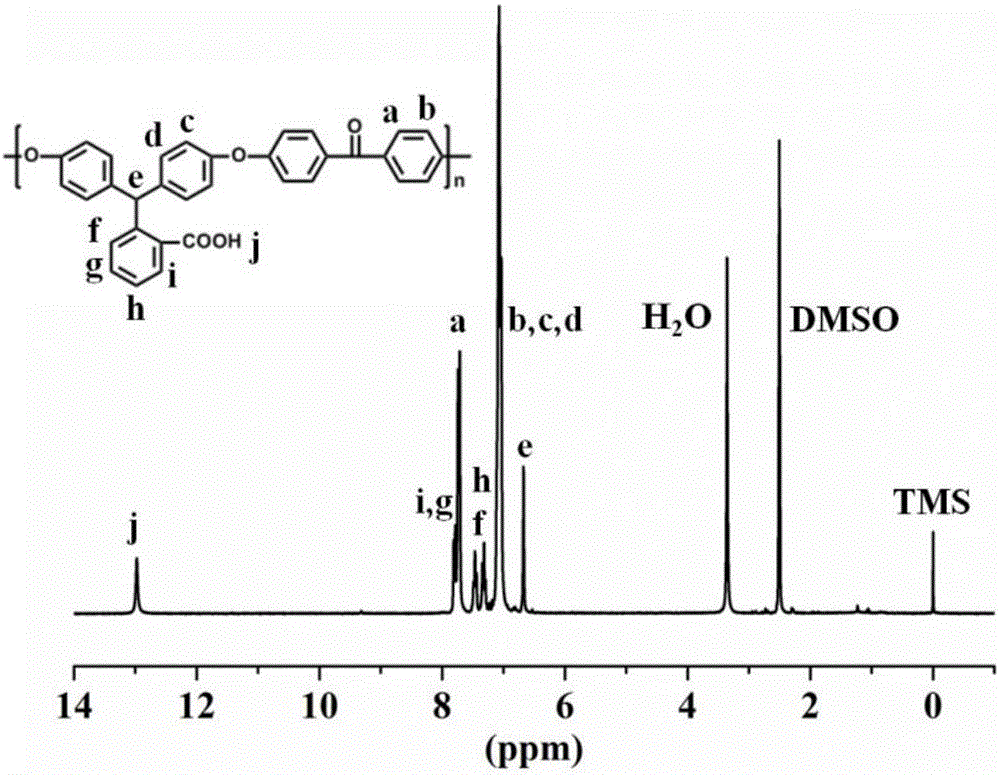

[0043] Phenolphthalein (0.50mol), dichlorodiphenylsulfone or tetrafluorodiphenylsulfone or difluorobenzophenone or dichlorodiphenylsulfone+difluorobenzophenone (0.50mol), K 2 CO 3 (0.85mol), DMSO (1.5L) were added to a dry 2.0L three-neck flask filled with nitrogen atmosphere; under the protection of nitrogen, the toluene water separation reaction was carried out at 140°C for 4-6h; the toluene was evaporated and the temperature was raised to 180°C, and the reaction 12 to 24 hours; after the reaction system is cooled to room temperature, pour the mixed system into 4.5L of 10% HCl aqueous solution to obtain a fibrous polymer; collect the obtained polymer, wash with water and ether in sequence, and then vacuum-dry at 120°C After 24 hours, the target polymer was obtained with a yield greater than 95.0%. The reaction formula of the prepared polymer is as follows:

[0044]

[0045] According to the above reaction formula, it can be seen that when the reaction raw materials are ...

Embodiment 2

[0060] The nanofiltration membrane was prepared according to the method of Example 1, except that the dye solution for the corresponding flux and cut-off tests had a pH range of 5.0-7.0, and the test data results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com