Patents

Literature

73 results about "Trimethylsilanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylsilanol (TMS) is an organosilicon compound with the formula (CH₃)₃SiOH. The Si centre bears three methyl groups and one hydroxyl group. It is a colourless volatile liquid.

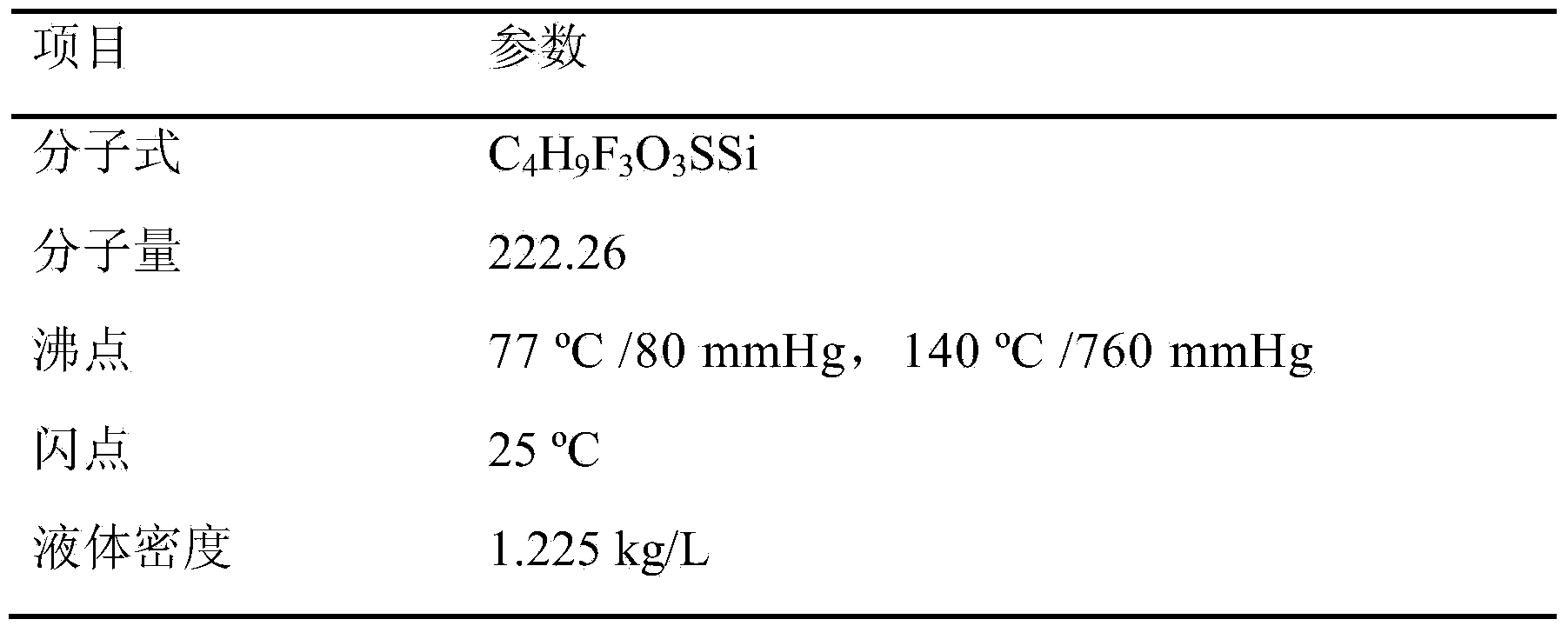

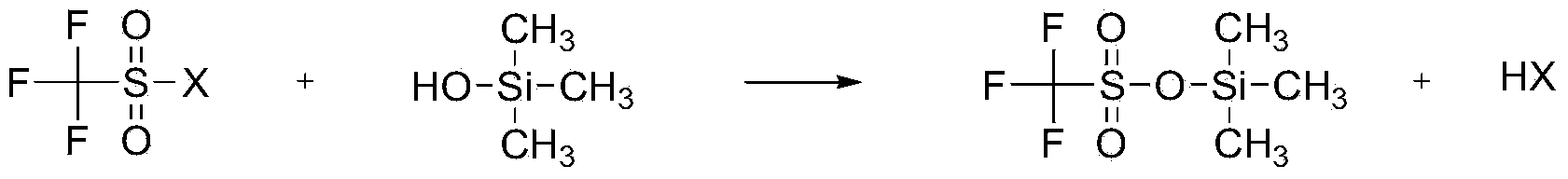

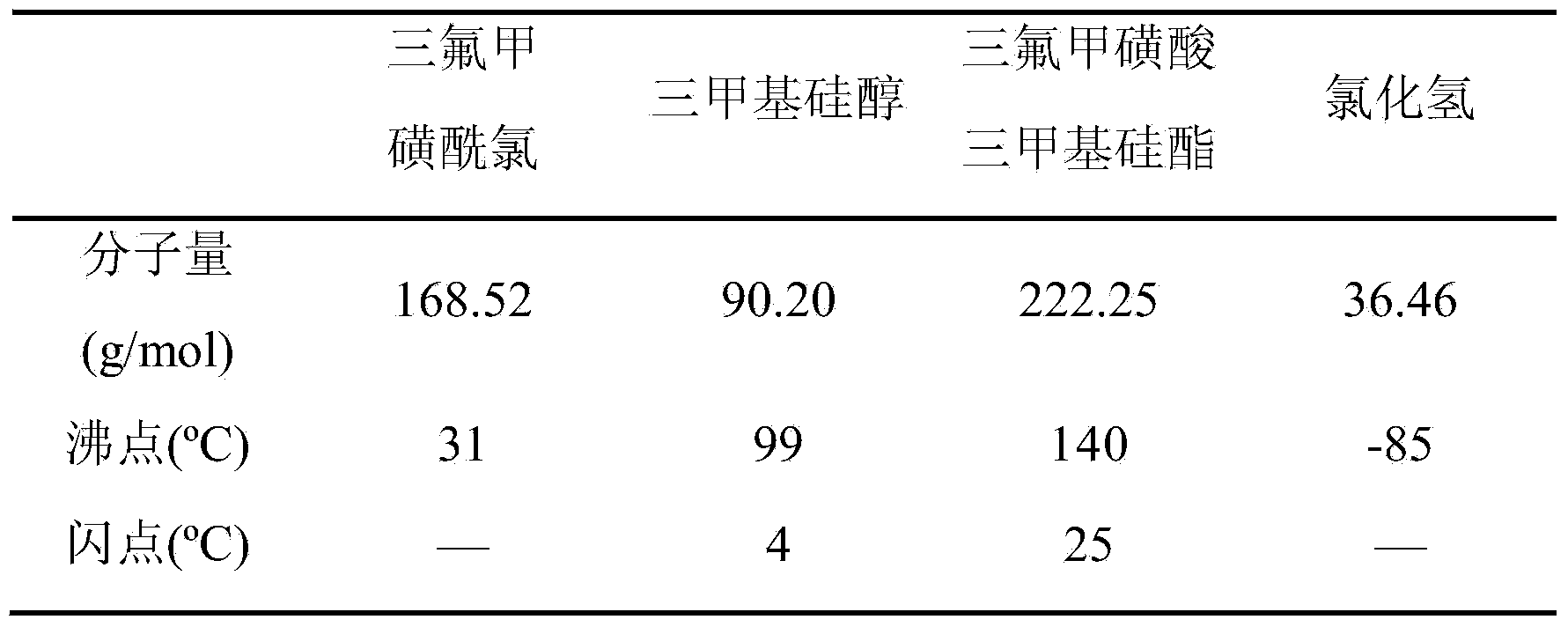

Preparation method of Trimethylsilyl trifluoromethanesulfonate

ActiveCN103665017AHigh quality contentLow mass contentSilicon organic compoundsTrimethylsilyl trifluoromethanesulfonateAlkyl transfer

The invention relates to a preparation method of Trimethylsilyl trifluoromethanesulfonate, and belongs to the field of a fine chemical industry. The preparation method comprises the following specific steps: a compound of which the general formula is CF3SO2X reacts with hydroxytrimethylsilane, wherein X is Cl, F or OSO2CF3, and hydroxytrimethylsilane is used as a silicon alkylation reagent of the reaction; the reduced pressure distillation is carried out on a reaction mixture after the reaction is finished to collect Trimethylsilyl trifluoromethanesulfonate of which the mass content is higher than 99.0%, wherein the mole ratio of the CF3SO2X to the hydroxytrimethylsilane in the reaction is (1.00: 0.80) to (1.00: 1.60), the reaction time is 1 to 10 hours, the reduced pressure distillation is carried out on the reaction mixture after the reaction is finished, and the pressure is 0.005 to 0.030MPa.

Owner:PERIC SPECIAL GASES CO LTD

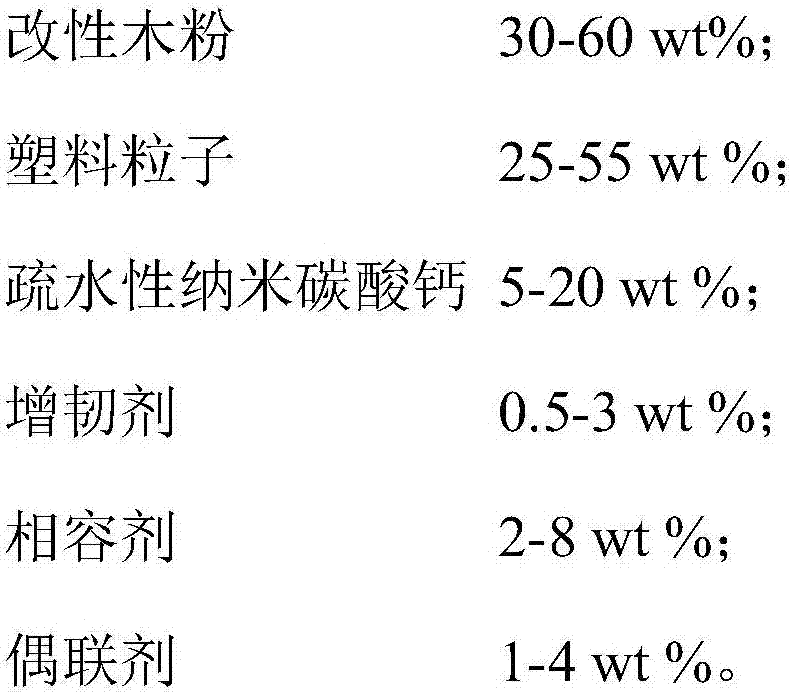

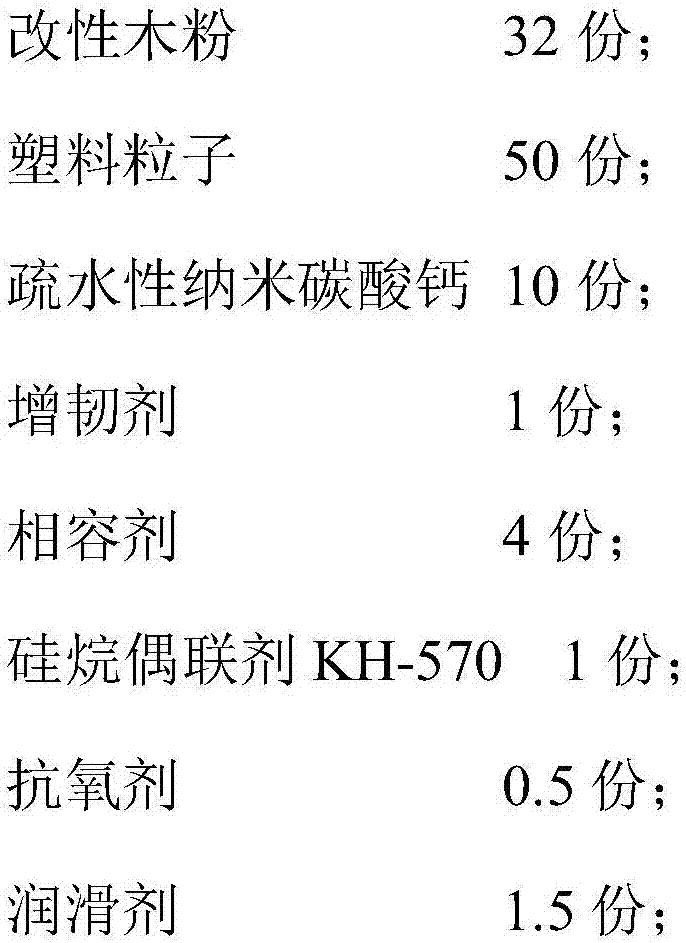

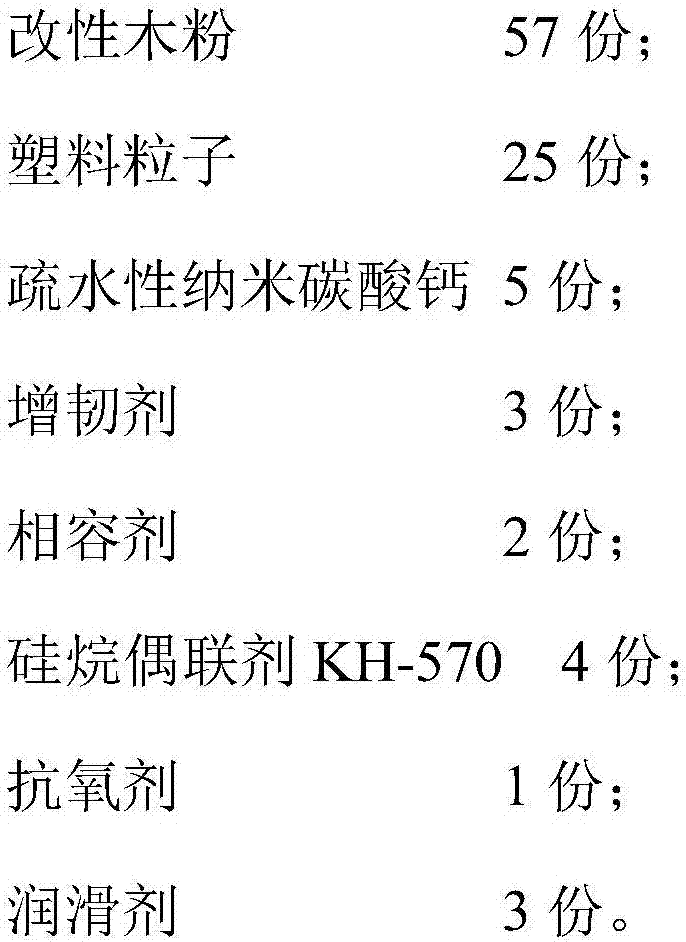

Biomass composite material with high hydrophobicity and preparation method thereof

A biomass composite material with high hydrophobicity and a preparation method thereof, the biomass composite material uses nano-calcium carbonate containing modified wood powder, plastic particles, toughening agent, compatibilizer, coupling agent, and hydrophobic filler The modified wood powder is first dehydrated and etherified by poly(dimethylsiloxane), trimethylsilanol and wood powder in a solvent, and then the hydroxyl groups on the surface of the wood powder are esterified Made by modified reaction. The biomass composite material provided by the invention has super-hydrophobicity, and when in contact with water, the stable contact angle of the surface is greater than 140°, water droplets cannot be immersed in the biomass composite board, the water absorption is extremely low, and the boiling resistance is excellent, so it can be used outdoors It has the advantages of anti-pollution and low water absorption, which greatly prolongs the service life of biomass composite materials outdoors.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

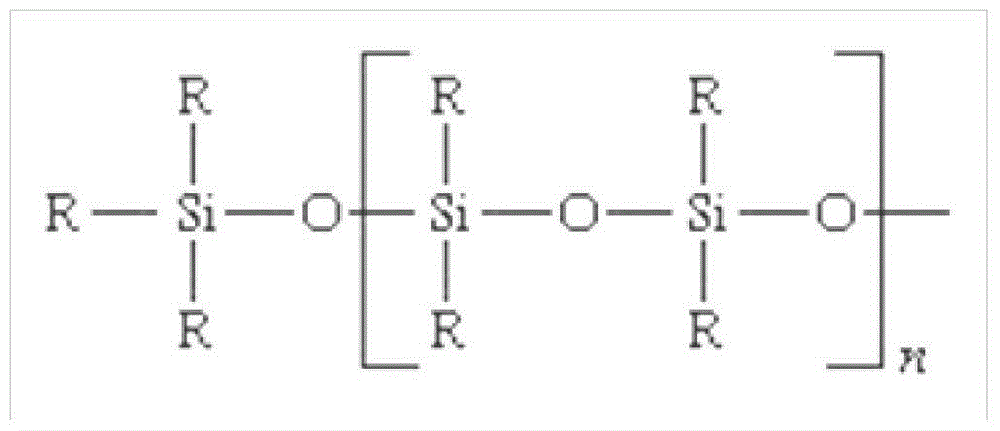

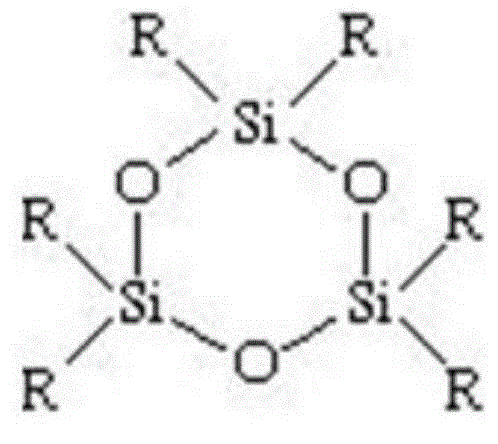

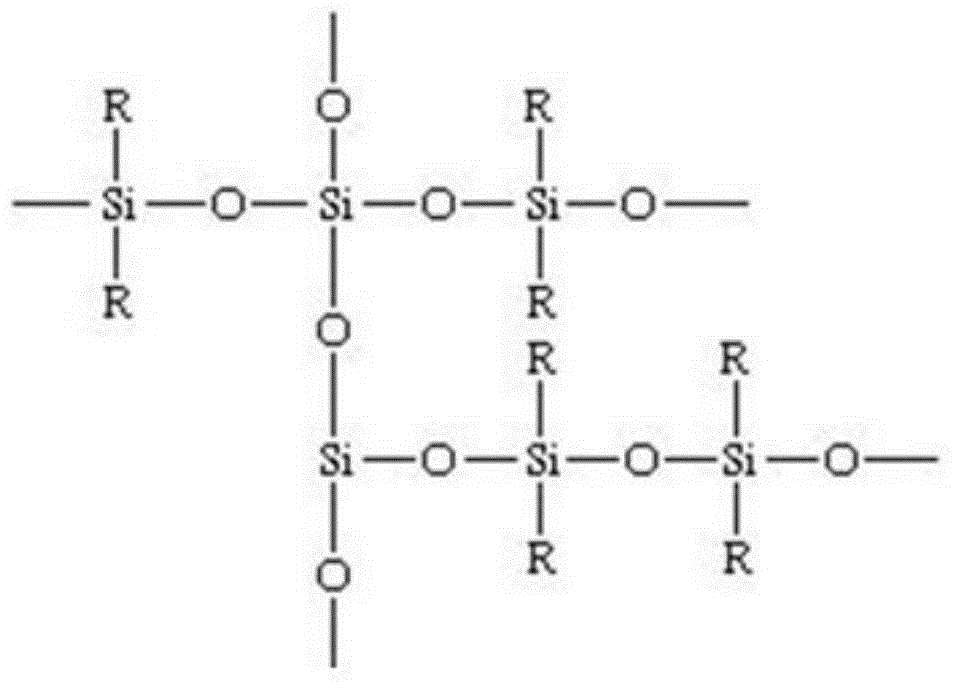

Method for splitting dimethyl dichlorosilane hydrolysate

ActiveCN104059099AHigh activityIncrease alkalinitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTrimethylsilanolHydrolysate

The invention discloses a method for splitting dimethyl dichlorosilane hydrolysate. The method comprises the following steps: carrying out load reaction onto strong-basicity macroporous anion exchange resin, potassium hydroxide, potassium trimethylsilanolate and [bmim]BF4 ionic liquid to obtain a composite catalyst after the reaction is ended; adding dimethyl dichlorosilane hydrolysate into a splitting kettle to obtain a ring-body mixture by splitting and re-arranging solvent oil, the composite catalyst and the hydrolysate; and washing with water to remove high-boiling point residues and low-boiling point residues to obtain products such as octamethylcyclotetrasiloxane D4, hexamethylcyclotrisiloxane and decamethylcyclopentasiloxane.

Owner:九江星成高分子材料有限公司

Anti-seep underground pipe culvert and preparation method thereof

InactiveCN105236842AImprove anti-seepage effectHigh compressive strengthSolid waste managementTrimethylsilanolPulverized fuel ash

The invention discloses an anti-seep underground pipe culvert. The anti-seep underground pipe culvert is prepared from cement, gravels, river sands, pulverized fuel ash, dicumyl peroxide, polyisobutene, ethyl carbamate, hydroxytrimethylsilane, water, an air entraining agent and water reducer. The invention further discloses a method for preparing the anti-seep underground pipe culvert. The method comprises the following steps of (1) mixing the cement, the gravels, the river sands, the pulverized fuel ash, the dicumyl peroxide, the polyisobutene, the ethyl carbamate, the hydroxytrimethylsilane, the air entraining agent and the water reducer to prepare a mixture M1; (2) pouring the mixture M1 into a reinforcement cage to form a pipe culvert blank body; and (3) maintaining the pipe culvert blank body to obtain the anti-seep underground pipe culvert. The anti-seep underground pipe culvert prepared by the method has an excellent water seepage prevention function, and has relatively high compressive strength and splitting tensile strength.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

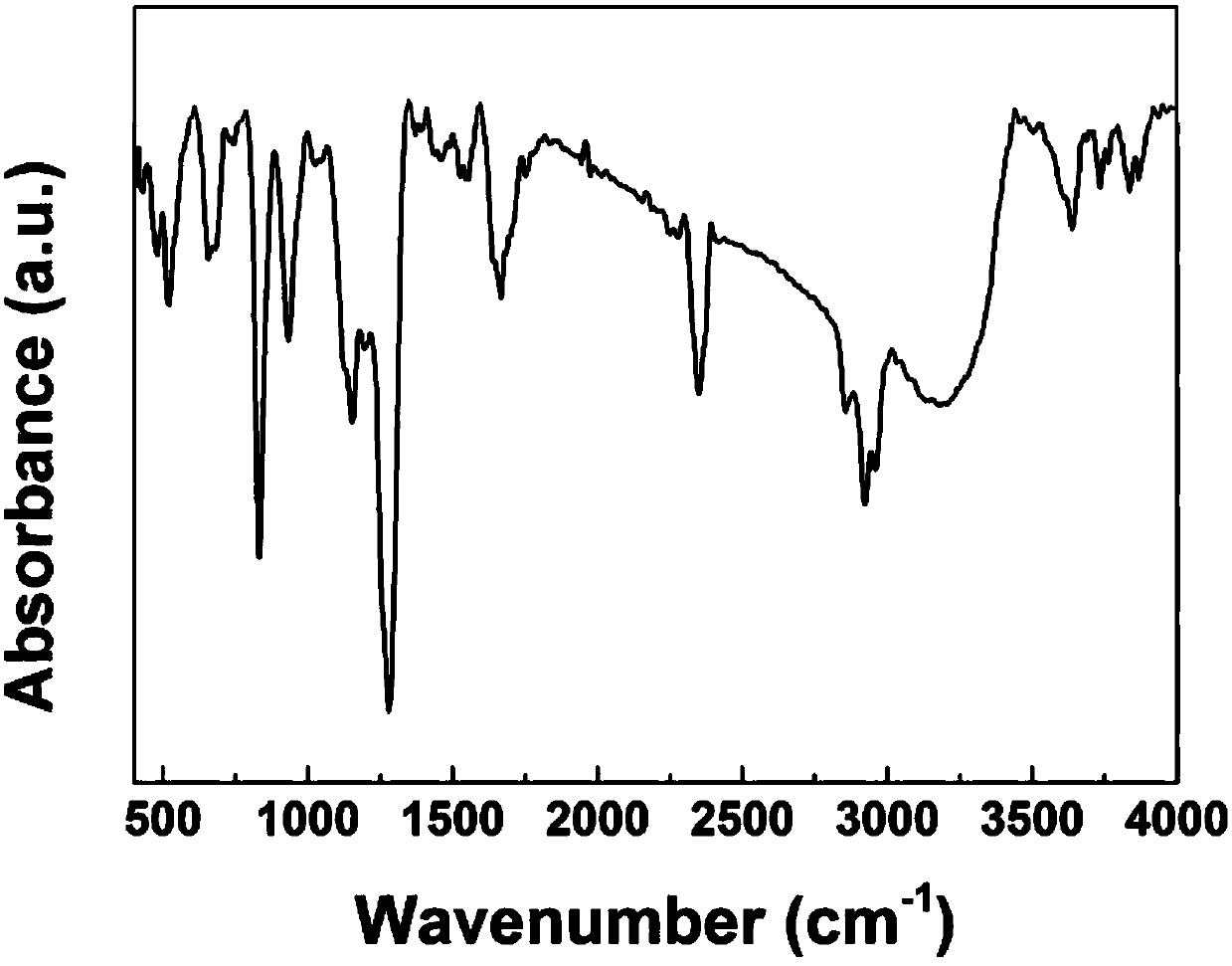

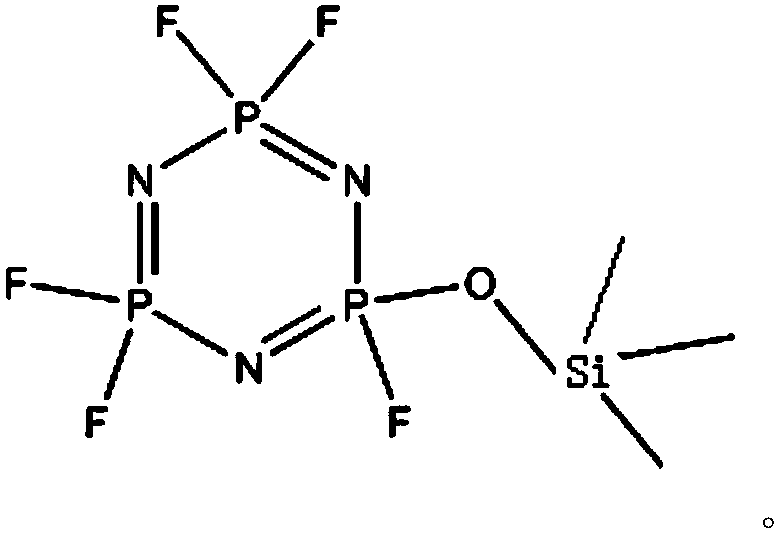

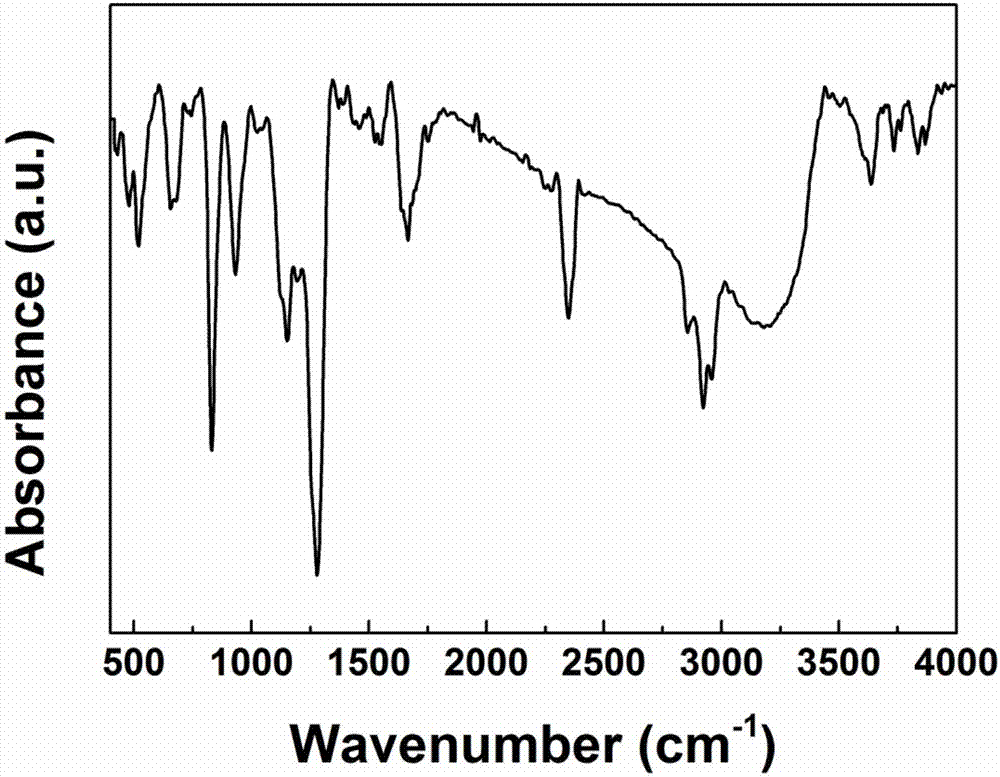

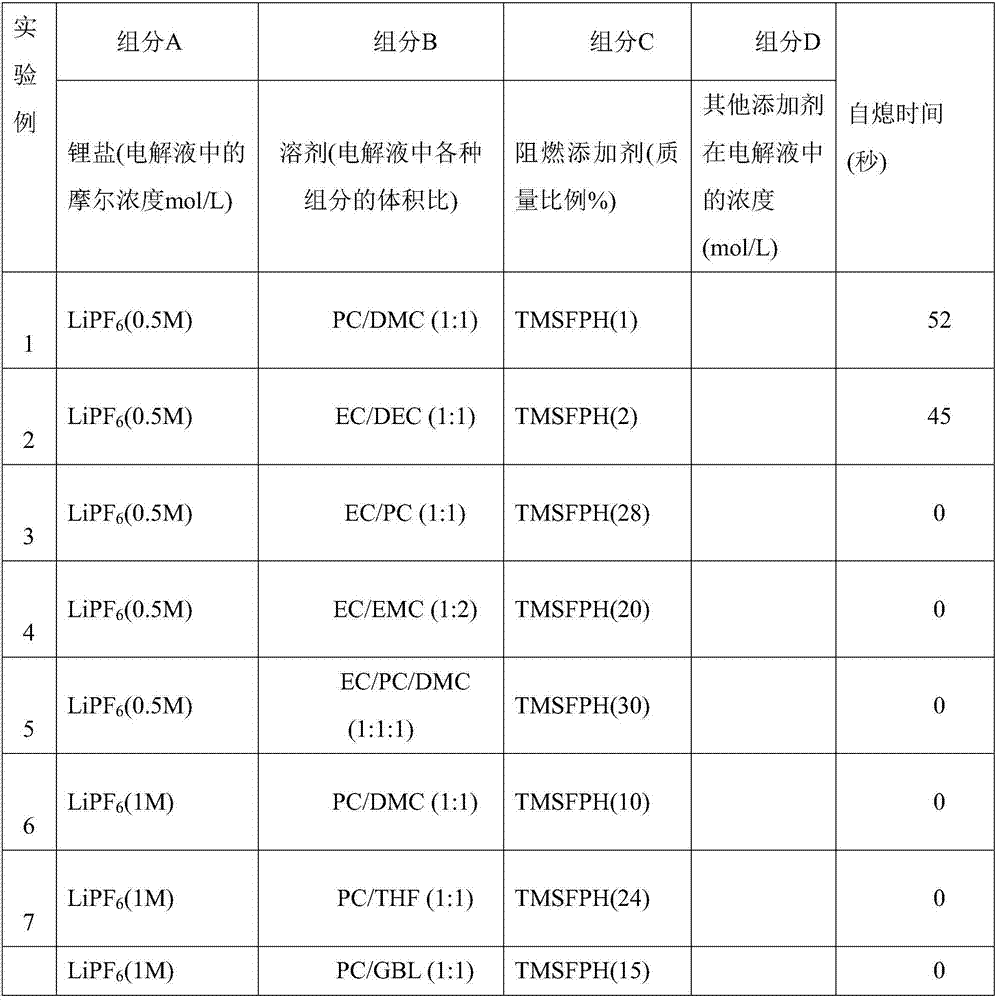

Efficient flame retardant siloxy fluoro cyclotriphosphazene and synthesis method thereof

InactiveCN107915759ALow viscosityImprove conductivityGroup 5/15 element organic compoundsSecondary cellsLithiumTrimethylsilanol

The invention discloses an efficient flame retardant siloxy fluoro cyclotriphosphazene and a synthesis method thereof. The synthesis method comprises the following steps: dissolving fluorinated cyclotriphosphazene in an organic solvent, adding a siloxy compound, performing reaction for 0.5-72h, and replacing one fluorine atom with one siloxy so as to obtain the siloxy fluoro cyclotriphosphazene. The siloxy compound is potassium trimethylsilanolate or sodium trimethylsilanolate or lithium trimethylsilanolate. The synthesis method disclosed by the invention has mild reaction conditions and goodreaction controllability and is convenient for industrial production; and furthermore, technological processes are simple, reactants and solvents can be recycled, and the purity and yield of productsare higher.

Owner:SHANDONG ZESHI NEW MATERIALS TECH CO LTD

Efficient flame retardant siloxy fluoro-cyclotriphosphazene and synthesis method thereof

The invention discloses an efficient flame retardant siloxy fluoro-cyclotriphosphazene and a synthesis method thereof. Fluoro-cyclotriphosphazene is dissolved into an organic solvent, and a siloxy compound and a catalyst are added to perform a reaction for 0.5-72h to replace fluorine atoms by siloxy to obtain siloxy fluoro-cyclotriphosphazene, wherein the siloxy compound is potassium trimethylsilanolate, sodium trimethylsilanolate or lithium trimethylsilanolate. The adopted synthesis method is mild in reaction conditions, high in reaction controllability and capable of realizing industrial production conveniently; and in addition, the technological process is simple, the reactants and the solvent can be recycled, and the product purity and yield are relatively high.

Owner:SHANDONG UNIV

Aluminum-based composite heat dissipation material with low thermal impedance for LED

InactiveCN104141072AImprove sintering performanceGood compatibilityHeat-exchange elementsHeat conductingMixed materials

The invention relates to the lamp heat dissipation materials and specifically relates to an aluminum-based composite heat dissipation material with low thermal impedance for an LED and a production method thereof. The heat dissipation material is prepared from the following materials in parts by weight: 76-78 parts of aluminum, 12-15 parts of aluminum nitride, 8-10 parts of titanium dioxide, 1-3 parts of strontium carbonate, 2-3 parts of sodium trimethylsilanolate, 4-5 parts of sodium polyacrylate, 1-3 parts of oil amine polyoxyethylene ether, 10-12 parts of organic silicon resin, 0.2-0.4 part of acetamide and 4-5 parts of auxiliaries. The heat dissipation material disclosed by the invention is integrated with advantages of components such as aluminum, aluminum nitride, organic silicon resin, and the like, and also has good heat-conducting property and insulating property; the materials are grinded and dispersed in mixed aqueous liquor of sodium polyacrylate and acetamide, so that compatibility of the materials is improved; the auxiliaries are added, so that sintering performance of the mixed materials is improved; the heat dissipation material is compact and ordered in internal structure, smooth and compact in surface, quick in heat transmission and heat dissipation, low in thermal impedance, and capable of quickly lowering the temperature of the LED lamps so as to guarantee the lamps to efficiently and stably light, and thus, service lives of the LED lamps are prolonged.

Owner:BENGBU GAOHUA ELECTRONICS

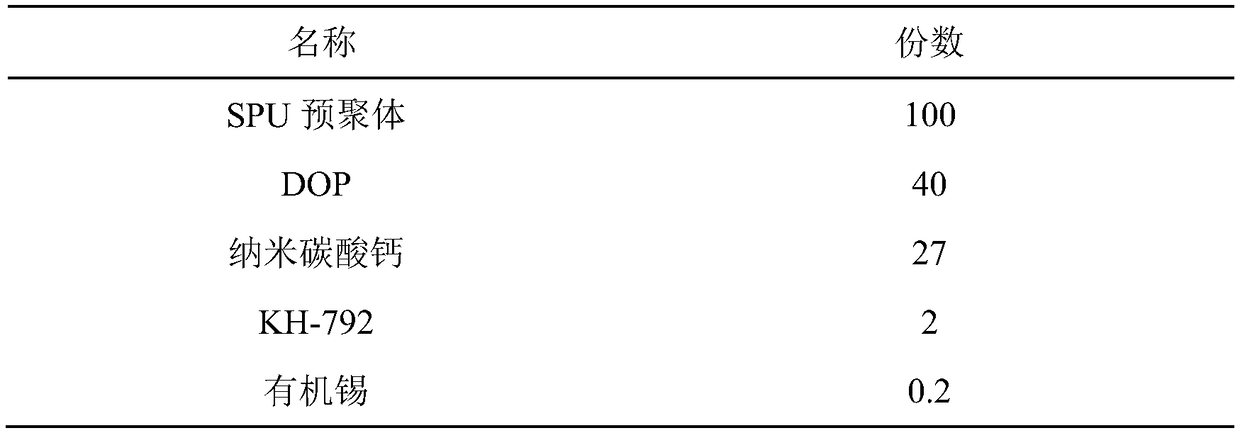

Preparation of nano calcium carbonate for siloxane end-capped polyurethane sealant

ActiveCN109504130ALow water absorptionGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDispersitySilanes

The invention discloses preparation of nano calcium carbonate for a siloxane end-capped polyurethane sealant, the proportion of refined lime milk is regulated to 1.060-1.080, a bubbling carbonation reaction kettle is then introduced, a CO2 mixed gas is introduced to implement the carbonation reaction, the reaction is stopped when the pH of a reaction liquid is equal to 7.0, a nano calcium carbonate suspension is obtained; the nano calcium carbonate suspension is heated to 75-85 DEG C, a surface treating agent compounded from hydroxytrimethylsilane, dimethylformamide and fatty acid salt is added, the addition quantity of the surface treating agent is 4.0-5.0% of the mass of a calcium carbonate dry basis in the suspension, the surface modifying is finished after stirring for 30-60 minutes, amodified calcium carbonate suspension is obtained; the modified calcium carbonate suspension is filter-pressed, dehydrated, dried and pulverized to obtain a nano calcium carbonate product. After thecalcium carbonate prepared through the method fills SPU (siloxane end-capped polyurethane), the problem of dispersity of calcium carbonate in the SPU sealant is solved, and the elongation at break andthe storage stability of the SPU sealant are also obviously improved.

Owner:ANHUI PROVINCE XUNCHENG CITY HUANA NEW MATERIAL TECH CO LTD

Preparation method of polymer for packaging large-scale integrated circuit

The invention discloses a preparation method of a polymer for packaging a large-scale integrated circuit. The polymer comprises the main raw material of 95-65 parts by mass of alpha,omega-dihydroxyl polydimethylsiloxane or alpha,omega-hydroxyl poly(dimethyl-methylvinyl)silica with the polymerization degree of 5-30 and comprises the auxiliary raw material of 5-35 parts by mass of methylvinyl MQ silicon resin or methyl MQ silicon resin with the M / Q value of 0.6-0.9. The preparation method comprises the following steps: feeding the main raw material and the auxiliary raw material into a reaction kettle, and stirring for 20-60 minutes at a speed of 40-120 rpm; heating to 50-130 DEG C at a speed of 2 DEG C per minute; after the system is uniformly mixed and the temperature is stable, stirring at constant temperature for 1-4 hours in the presence of a catalyst, namely sodium trimethylsilanolate or potassium trimethylsilanolate accounting for 0.01%-0.1% of the mass parts of the main raw material; after the reactant turns into transparent colloid, stopping heating and continuously stirring until the reactant is cooled to room temperature to obtain the target product. The body resistance is higher than 1,013omega, the thermal conductivity is lower than 1.40W / mK, and the polymer can tolerate irradiation not lower than 109rad while good elasticity is still kept.

Owner:SOUTHEAST UNIV

Wire brush with excellent wear resistance, and preparation method thereof

InactiveCN105369598AGuaranteed mechanical propertiesImprove wear resistanceFibre treatmentFiberCarbon fibers

The invention discloses a wire brush with excellent wear resistance, and a preparation method thereof. According to the preparation method, the outside of the wire brush is coated with a wear-resistant particle layer, and the wire brush is prepared from following raw materials, by weight, 25 to 30 parts of tungsten carbide powder, 10 to 15 parts of tetrafluoro-4-aminobenzotrifluoride, 3 to 5 parts of 3,5-dichlorophenyl isothiocyanate, 5 to 10 parts of 1,2-bis(tosyloxy)ethane, 8 to 10 parts of 1,3-dichloro-2-butene, 6 to 8 parts of polyisoprene, 3 to 5 parts of a thermosetting resin, 5 to 8 parts of carbon fiber, 1 to 2 parts of ethyl cellulose, 3 to 5 parts of calcium acetate, 1 to 2 parts of glass fiber, 40 to 50 parts of hydroxytrimethylsilane, 15 to 20 parts of fatty acid polyglycol ester, and 6 to 8 parts of an accelerant. Compared with the prior art, the preparation method is different from conventional production technology wherein wear-resistant materials are added into wire brushes directly, the outside of the wire brush is coated with the wear-resistant particle layer, so that original mechanical properties are maintained, adhesion force of the wear-resistant particle layer is improved, service life of the wear-resistant particle layer is prolonged, and wear resistance of the wire brush is improved.

Owner:安徽天瑞塑业股份有限公司

Mould-proof and color fixing treatment agent for corn bran and using method of agent

InactiveCN106378847AHigh whitenessImprove surface activityWood treatment detailsReed/straw treatmentTrimethylsilanolBenzene

The invention belongs to the technical field of treatment agents of weaving raw materials, and particularly relates to a mould-proof and color fixing treatment agent for corn bran and a using method of the agent. The agent is made of raw materials of d-mycose, hydroxytrimethylsilane, dihydrogen hexachloroiridate, mulberry latex, titanium potassium oxalate, clover size, armor amino benzene acetone and the like. Compared with the prior art, the agent has the following beneficial effects that sulphur, chalcas and pig manure are used for carrying out stifling on the corn bran, the effective sterilization effect is achieved, the whiteness and the surface activity of the corn bran are improved, a dyeing agent can be more effectively attached to the surface of the corn bran, then, the mould-proof and color fixing agent is used for treatment, the dyeing agent on the surface of the corn bran and corn bran surface fibers are better combined, the anti-tarnish capability of the corn bran is improved, meanwhile, the oxidization-resistance capacity of the corn bran is improved, the corn bran is bright in color, durability and the high mould-proof effect are achieved, and meanwhile, ornamental value of corn bran products is greatly improved.

Owner:安徽宏润工艺品有限公司

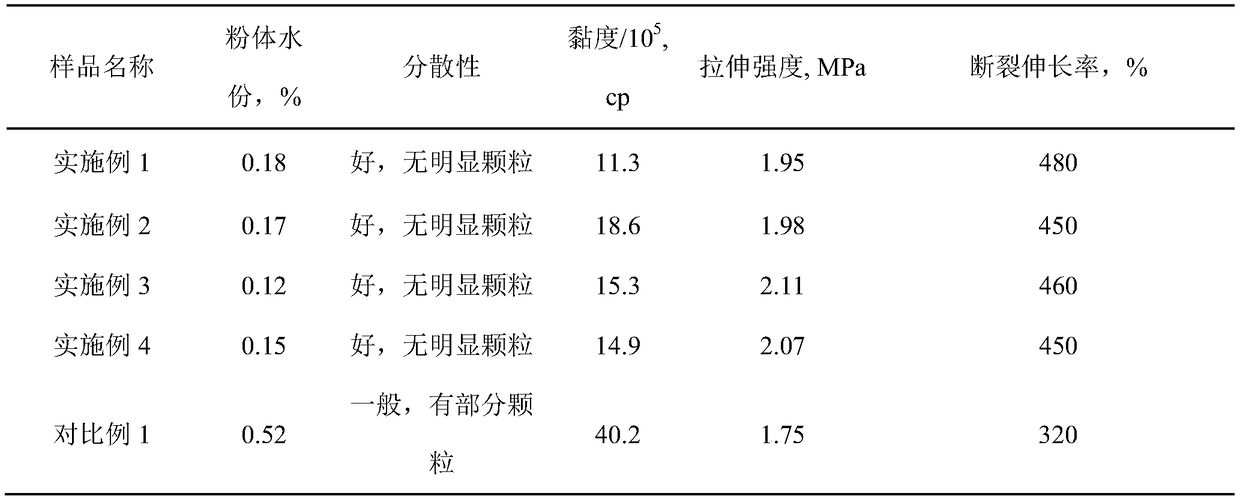

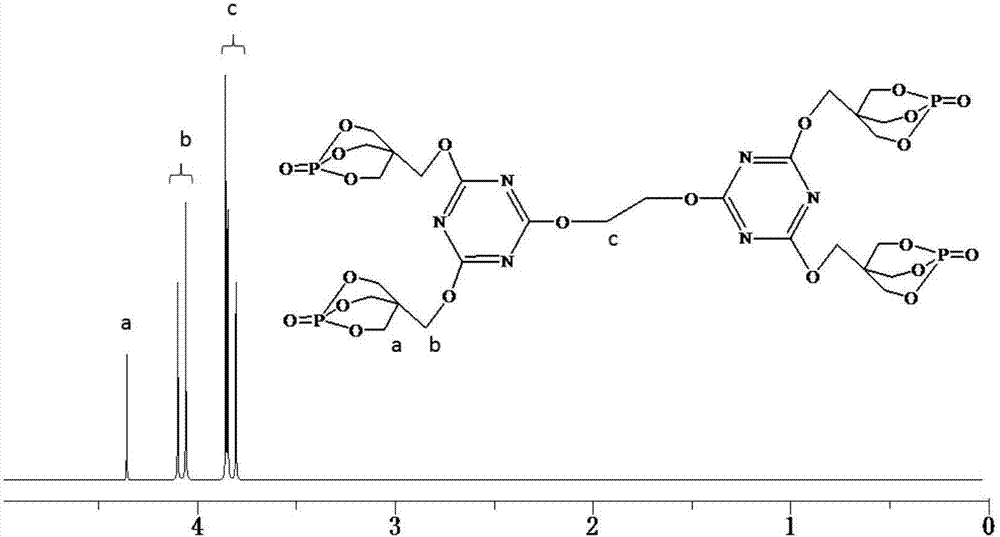

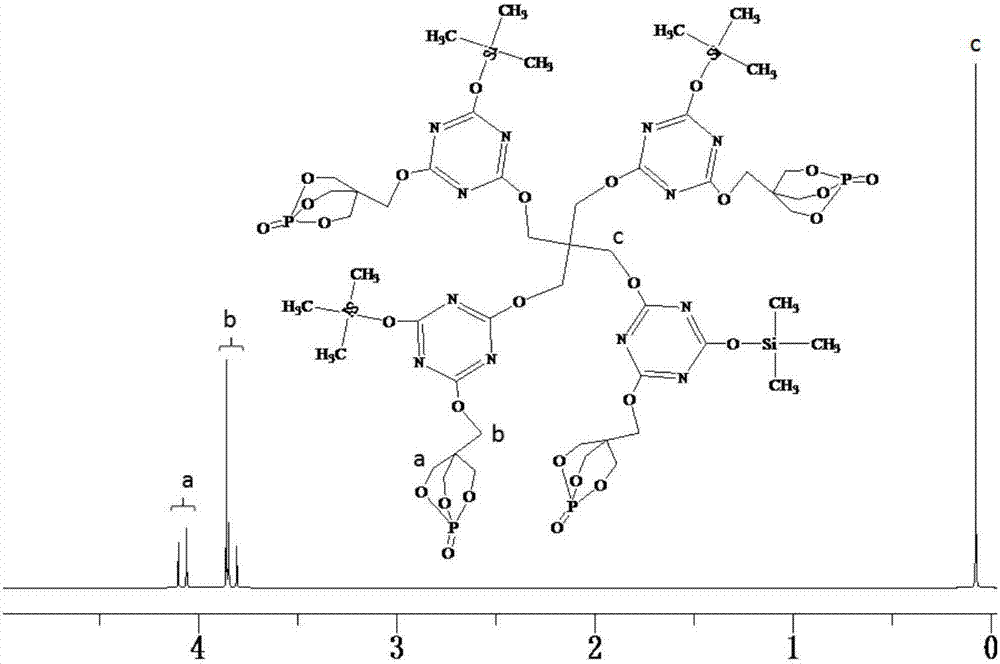

Hyperbranched expanded type flame retardant and preparation method thereof

ActiveCN107129595ALow hygroscopicityImprove water resistanceGroup 5/15 element organic compoundsDispersityPolymer science

The invention discloses a hyperbranched expanded type flame retardant and a preparation method thereof. The method comprises the following steps: taking one or a mixture of any two of 1-oxo-4-hydroxymethyl-1-phospha-2,6,7-trioxabicyclo[2,2,2]-octane, trimethylsilanol and sodium lignosulphonate as a first monomer and taking cyanuric tricholoride as a second monomer; enabling the first monomer and the second monomer to react for 2.5h to 5.5h in an organic solvent at 30 DEG C to 50 DEG C in the presence of an acid binding agent A, so as to generate a di-substituted product; adding a third monomer polylol into the di-substituted product and reacting for 3h to 6h at 70 DEG C to 95 DEG C for in the presence of an acid binding agent B, so as to obtain the hyperbranched expanded type flame retardant. The adding amount of the hyperbranched flame retardant disclosed by the invention in a matrix is low and the branching degree of the flame retardant is increased so that the flame retardant is difficult to crystallize and has no chain entanglement; the dispersity of the flame retardant in the matrix and the compatibility of the flame retardant and the matrix are improved and the moisture absorption of the flame retardant is reduced; the water resistance and migration resistance of the flame retardant are improved.

Owner:ZHEJIANG UNIV OF TECH +1

Preparation method of MQ branched-chain modified silicon resin polymer for large-scale integrated circuit package

The invention discloses a preparation method of an MQ branched-chain modified silicon resin polymer for large-scale integrated circuit package. Alpha, omega-dyhydroxyl polydimethylsiloxane or alpha, omega-hydroxyl poly(dimethyl-methyl vinyl) silicon dioxide is taken as a main raw material, methyl vinyl MQ silicon resin with the value of M / Q value being 0.6-0.9 or methyl MQ silicon resin is taken as an auxiliary raw material, the mixture is stirred to have a reaction for 45 minutes at the rotation speed of 70 revolutions per minute, the temperature is raised to 50-130 DEG C, and the temperature rising rate is 2 DEG C per minute; sodium trimethylsilanol or potassium trimethylsilanol accounting for 0.01%-0.1% of the main raw material by mass is added to serve as a catalyst, the mixture is stirred for 1-4 hours at the constant temperature, and a target product is obtained. The tensile strength, the impact strength and the adhesive property of the polymer prepared with the method are excellent, the resistance is higher than 1,013 omega, the heat conductivity is lower than 1.40 W / mK, the silicon resin polymer can resist radiation not lower than 109 rad, and the elasticity is good.

Owner:江苏三木化工股份有限公司

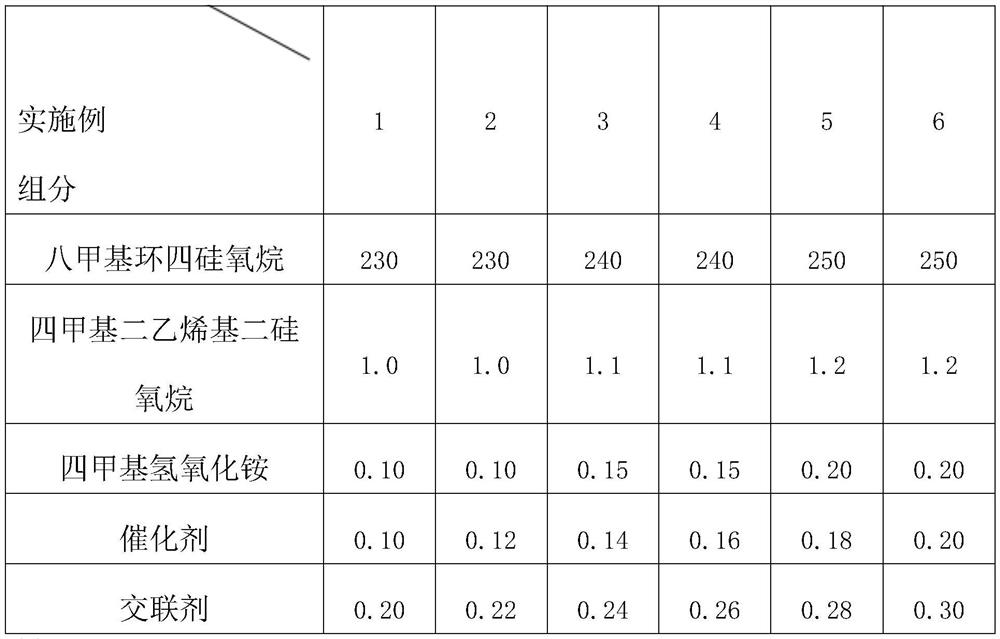

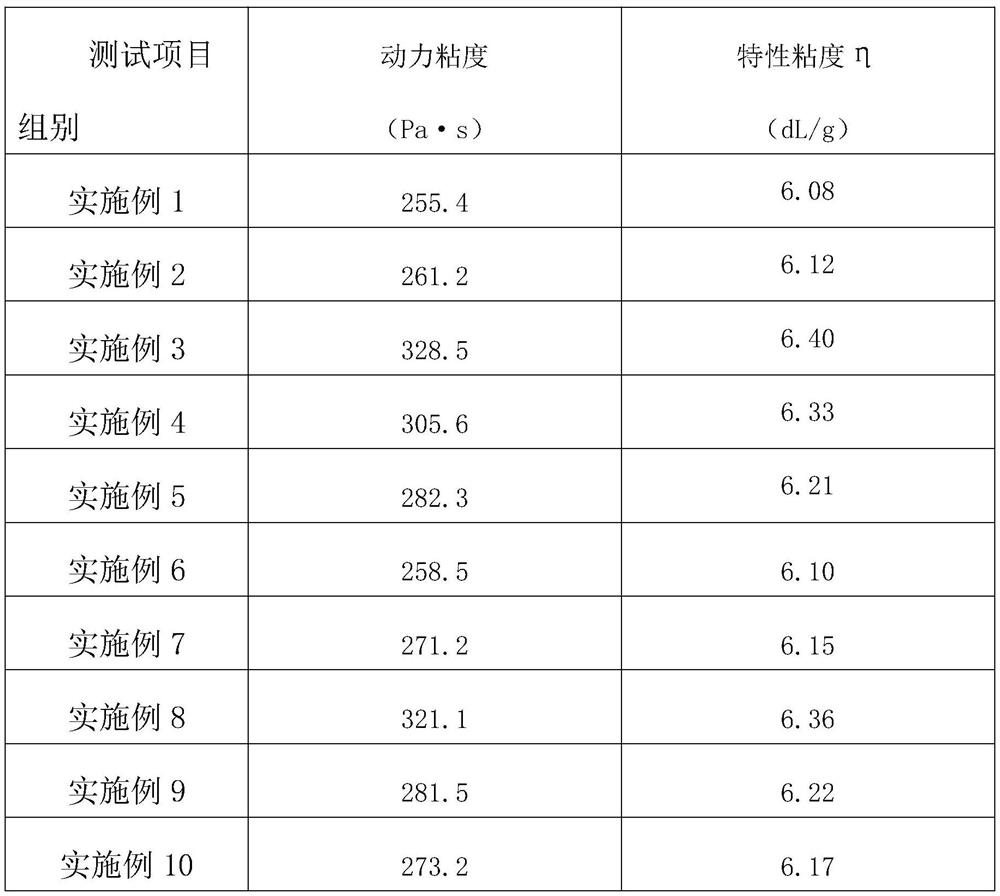

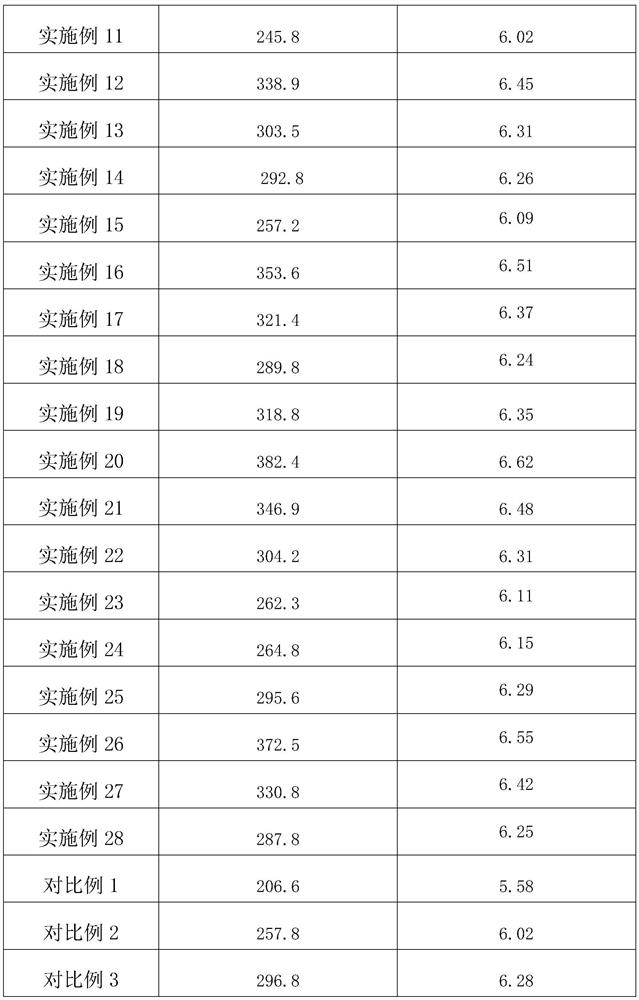

Silicone rubber and production process thereof

The invention relates to the field of silicone rubber, and particularly discloses silicone rubber and a preparation method thereof. The silicon rubber is prepared from the following raw materials in parts by weight: 230 to 250 parts of octamethylcyclotetrasiloxane; 1.0 to 2.0 parts of tetramethyl divinyl disiloxane; 0.1 to 0.2 part of tetramethylammonium hydroxide; 0.1 to 0.2 part of a catalyst; 0.2 to 0.3 part of a cross-linking agent; the catalyst is prepared from sodium trimethylsilanolate, tetramethyl tetravinyl cyclotetrasiloxane and hexamethyl cyclotrisiloxane. The preparation method has the advantages of being simple, convenient and easy to operate, and the prepared silicone rubber has the advantage of being high in viscosity and can meet most requirements of the market.

Owner:上海达华药业有限公司

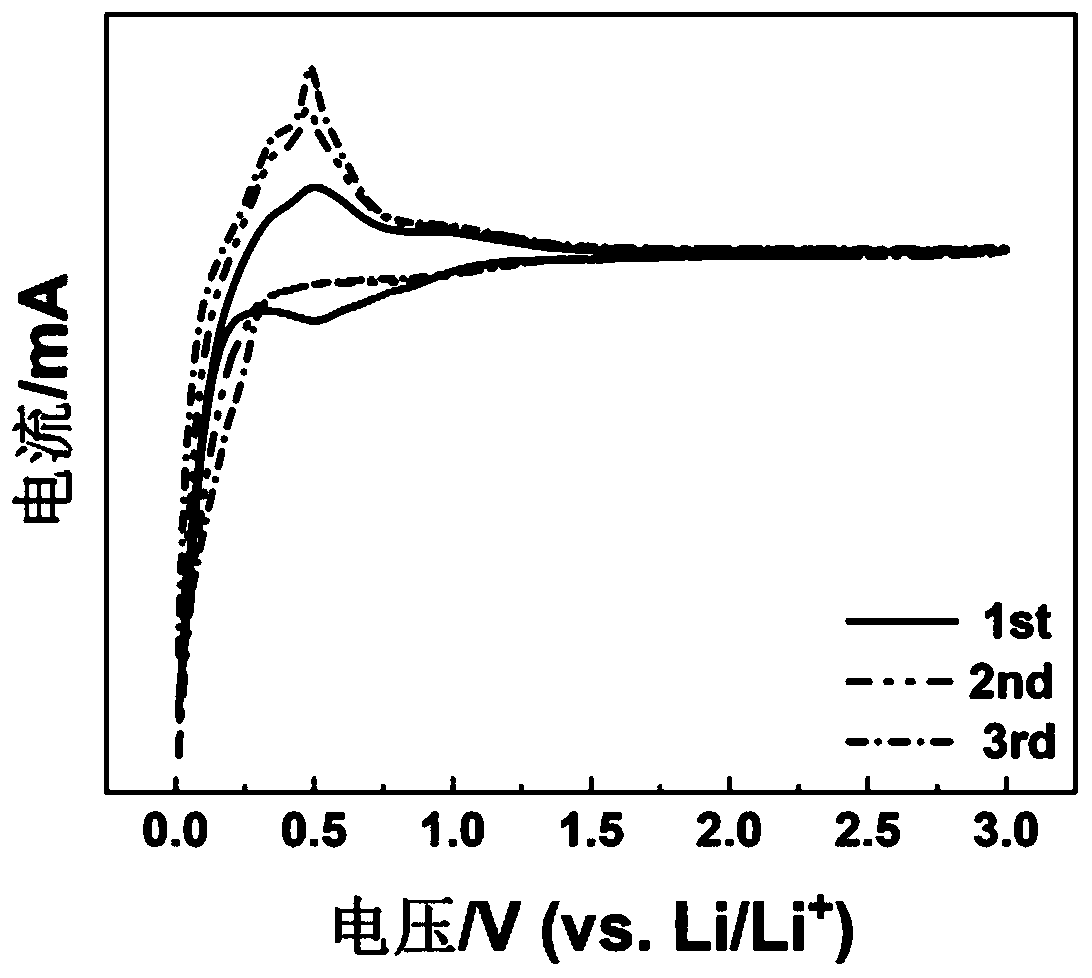

Flexible MXene/Si composite material as well as preparation method and application thereof

The invention discloses a flexible MXene / Si composite material as well as a preparation method and application thereof. The preparation method comprises the steps of putting an MXene film into an electroplating solution for electro-deposition, and depositing a layer of silicon film on the surface of the MXene film. The electroplating solution is a mixed solution of a silicon source, a phase transfer catalyst and an organic solvent, wherein the silicon source is one or a mixture of two or more of silicon tetrachloride, hexamethyldisilane, cyclopentyl trichlorosilane, methoxytrimethylsilane, hexaphenyl disiloxane, hexaphenyl cyclotrisiloxane, tetrakis (trimethylsiloxy) silane, ethoxytriphenylsilane, triisopropylsilane, trimethylsilanol potassium, trichlorosilane, tetraethoxysilane and silicon bromide. The preparation method disclosed by the invention is simple and feasible. The production cost can be reduced, and the obtained MXene and silicon have relatively strong acting force.

Owner:SHANDONG UNIV

Waterborne paint

InactiveCN107513318AImprove anti-pollution performanceImprove adhesionAntifouling/underwater paintsPaints with biocidesTrimethylsilanolState of art

The invention discloses waterborne paint. The waterborne paint is prepared from the following raw materials in parts by mass: 20 to 50 parts of water, 2.0 to 6.0 parts of potassium trimethylsilanolate, 0.35 to 0.1 part of dispersing agent, 0.05 to 0.65 part of wetting agent, 20 to 45 parts of titanium dioxide, 8 to 25 parts of filler, 25 to 45 parts of emulsion and 1 to 2 parts of curing agent. As the waterborne paint provided by the invention contains an organic silicone component, adopts ceramic particles and / or chitosan as filler, the adsorption performance of the ceramic particles and the thickening effect of the chitosan are utilized, the precipitation of salt and alkali or the pulverization of a paint film caused by too much filler or inappropriate ratio in the prior art is reduced, the addition of the chitosan also increases the bonding and adhesion between the components, and is conducive to improving film-forming properties and paint film strength; the waterborne paint provided by the invention is a waterborne product, which has a relatively good anti-pollution property, is suitable for production, and better suitable to people's needs.

Owner:陈瑞琼

Uniform doping method for trace silicon element of magnesium oxide sintered body target

The invention discloses a uniform doping method for a trace silicon element of a magnesium oxide sintered body target. According to the method, at first, a silicon source is dissolved and prepared into a precursor solution, when the adopted silicon source is sodium silicate, silicic acid, potassium silicate and other kinds of silicate capable of being dissolved in water, the silicon source is directly dissolved by deionized water, and volume setting is carried out, so that the precursor solution is formed; when the adopted silicon source is tetraethyl orthosilicate, trimethylhydroxysilane, silicon tetraacetate capable of being dissolved in organic solvent, the silicon source is dissolved in the organic solvent at first, and ethyl alcohol and water are used for carrying out volume setting, so that the precursor solution is formed. The precursor solution is mixed with a magnesium oxide raw material of a certain weight ratio in a ball mill to be prepared into slurry, so that uniform doping of the silicon element is completed. The slurry is subjected to spray granulation, compression moulding, sintering and other working procedures to be prepared into the magnesium oxide sintered body target doped with the trace silicon element. According to the method, doping time is short, uniformity is high, and the method is suitable for industrial application.

Owner:营口镁质材料研究院有限公司

Perlite heat preservation board and preparation method thereof

The invention discloses a perlite heat preservation board and a preparation method thereof. The heat preservation board comprises the following raw materials: modified expanded perlite, kaolin, cement, plant ash, diatomaceous earth, sodium trimethylsilanolate, epoxy chloropropane, divinyl benzene, ethyl orthosilicate, N,N'-methylene bisacrylamide, calcium sulphate, sodium chloroacetate, sodium chloride, sodium silicate and water; and the preparation method includes the following steps: uniformly mixing the modified expanded perlite, the kaolin, the cement, the plant ash and the diatomaceous earth to obtain a mixture A; uniformly mixing the remaining raw materials, adding water, and performing stirring to obtain a solution B; and adding the solution B into the mixture A, performing uniformstirring, pouring the stirred solution into a mold, performing compression moulding to obtain a perlite heat preservation board blank body, performing primary drying, performing secondary drying, andperforming tertiary drying to obtain the perlite heat preservation board. The perlite heat preservation board provided by the invention has good heat preservation performance, high compressive strength, is not easy to damage, and has high durability.

Owner:安徽宇力环保科技有限公司

Filtering system for a semiconductor processing tool

ActiveUS20090320681A1Premature replacementHigh concentration of pollutantsGas treatmentOrganic chemistryTrimethylsilanolTrimethylsilane

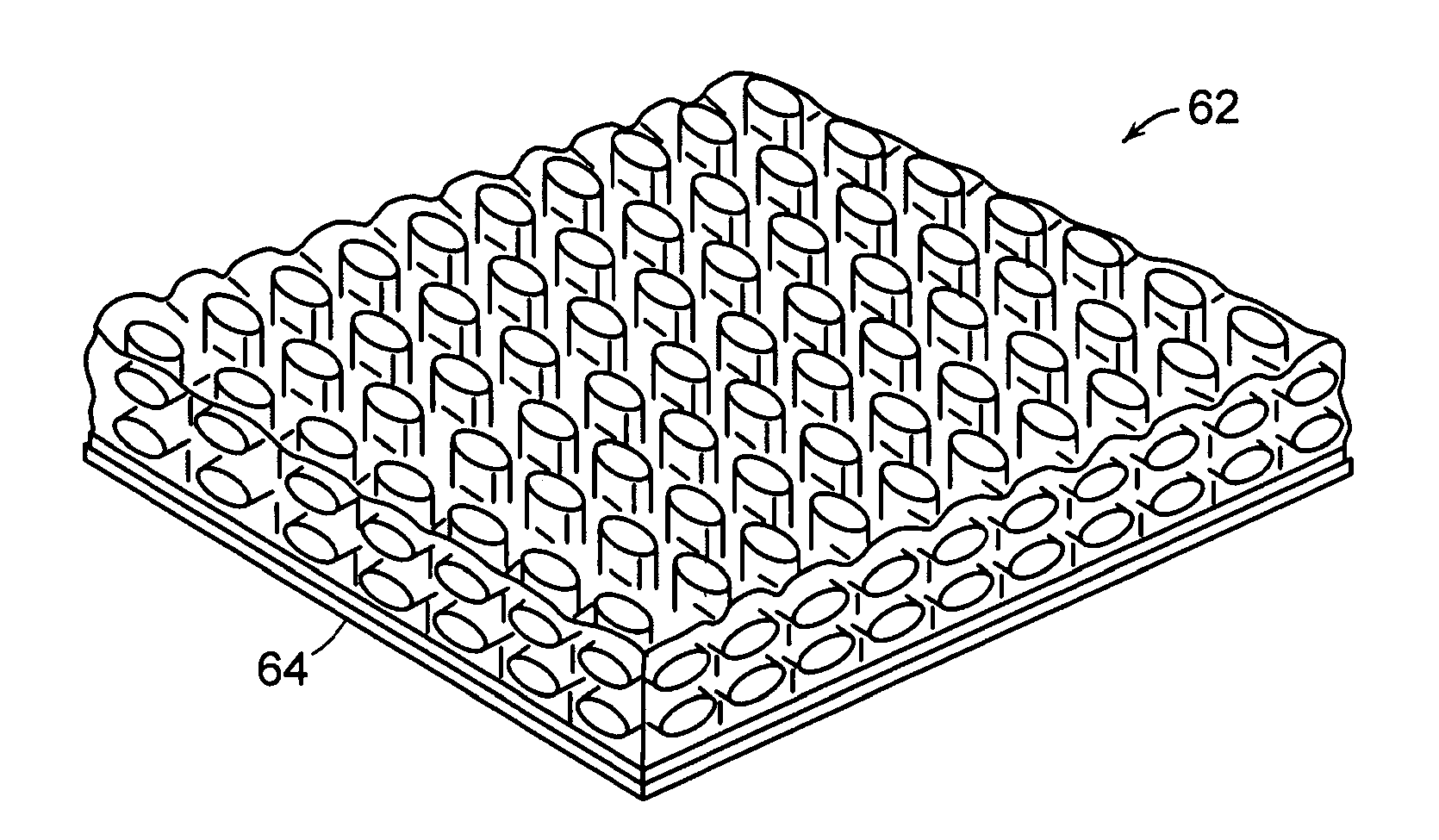

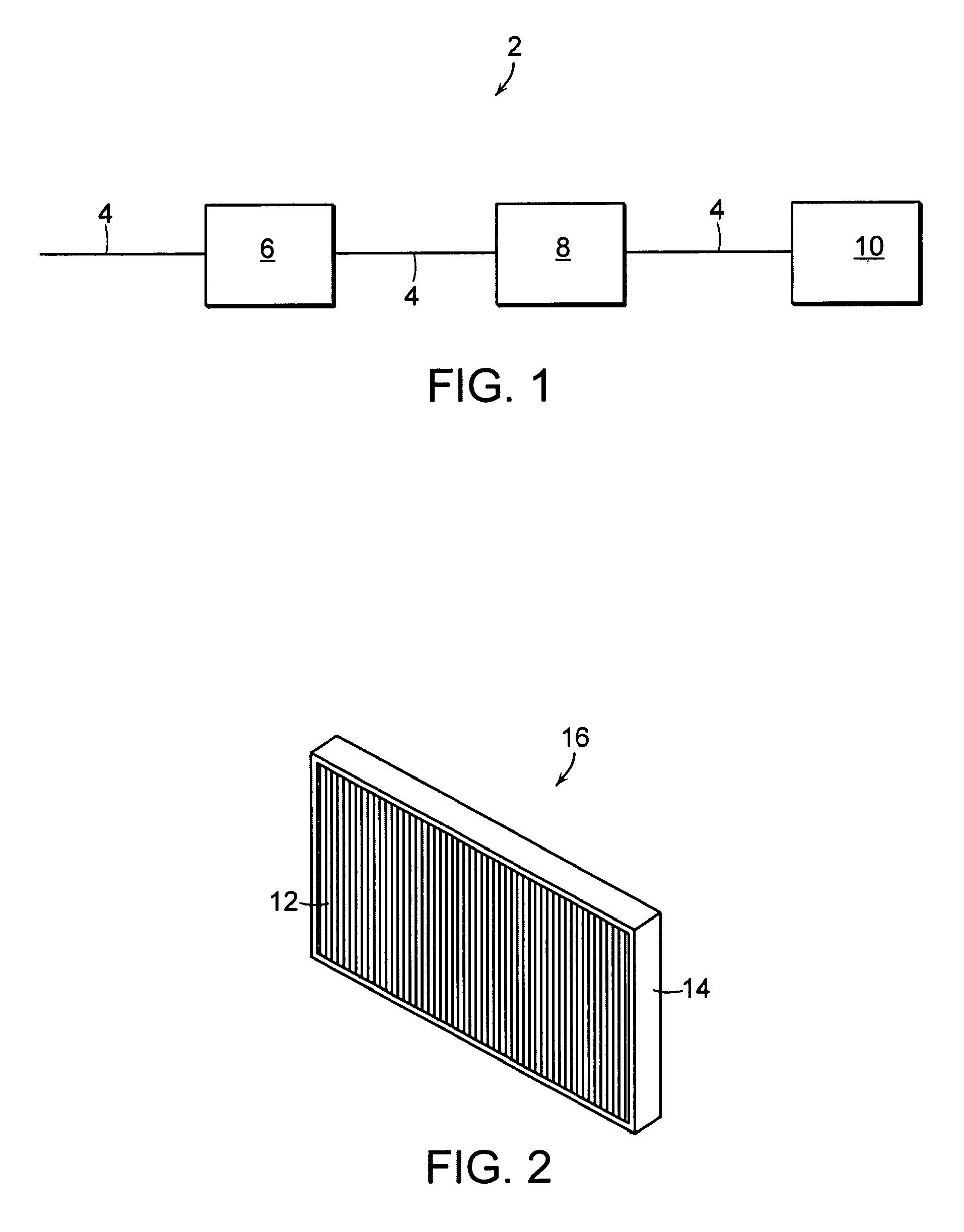

The present invention provides a filtering system for a semiconductor processing tool. In one embodiment, the filtering system is associated with the semiconductor processing tool. A system of the invention comprises a first and second filter layer in fluid communication with a gas flow path. The flow path is a gas stream comprising volatile silica containing compounds such as hexamethyldisiloxane and trimethylsilanol. The gas flow path passes through the first and second filter layer to fluidly communicate with the semiconductor processing tool. Preferably, the first filter layer of the filtering system is upstream along the gas flow path from the second filter layer. The medias of the first and second filter layers are selected and arranged based on given contaminant concentrations. The invention also provides a method for filtering gas containing hexamethyldisiloxane and trimethylsilanol in communication with a semiconductor processing tool, which employs a system comprising a first and second filter layer.

Owner:ENTEGRIS INC

Preparation method of trimethylsilanol

InactiveCN109438499ASolve difficulties that are difficult to completely separateSimple processSilicon organic compoundsTrimethylsilanolBis(trimethylsilyl)amine

The invention discloses a preparation method of trimethylsilanol. The preparation method includes the following steps of: S1, adding hexamethyldisilazane and phosphoric acid into a reaction kettle while stirring, wherein the molar ratio of the hexamethyldisilazane to the phosphoric acid is 1:(1 to 3); S2, after a period of heat-insulated reaction, performing stirring and rinsing by a solvent; S3,after standing and layering, performing separation to obtain the trimethylsilanol. The preparation method has the advantages that the method is used for preparing the trimethylsilanol, the process issimple in the production process, the process of a rectification stage is omitted in the washing procedure, the energy consumption is reduced, and the problem that the solvent is difficult to completely separate in the system is solved, so that the purity of a washed product can reach 99.6%, and the yield thereof can reach 92.8%; the subsequent separation is simple, reaction by-products, namely phosphoric acid aqueous solutions in which salt is dissolved, are few and can be recycled and reused, and the production cost is reduced.

Owner:湖北新蓝天新材料股份有限公司

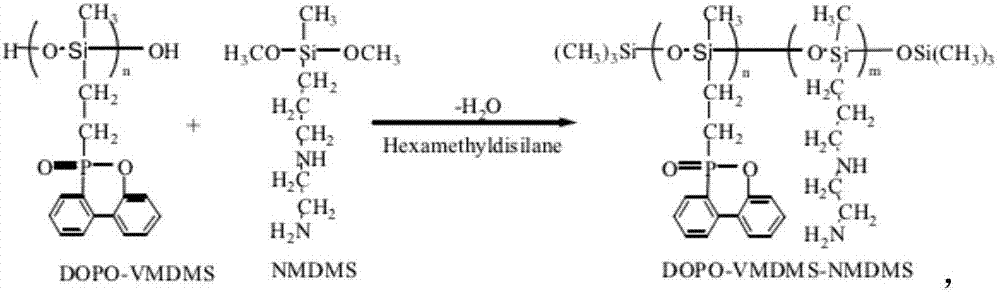

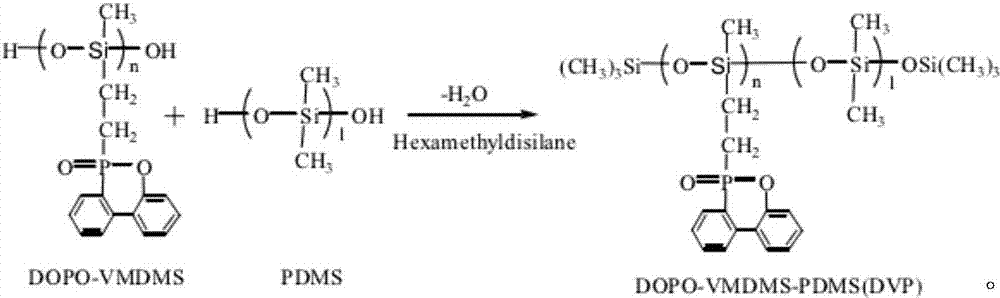

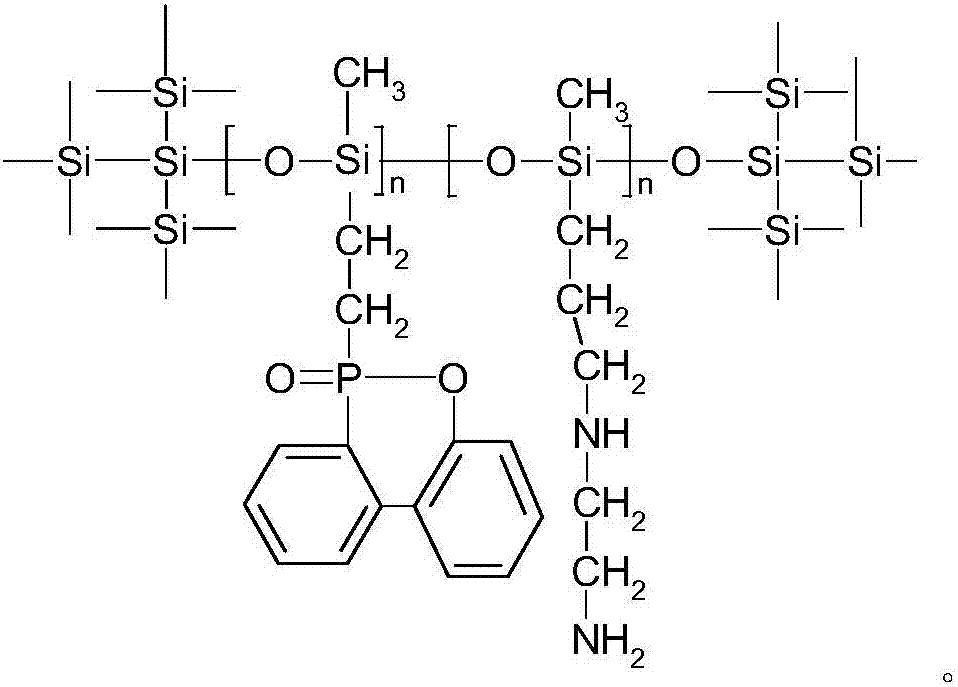

Preparing method of phosphorus based silane flame retardant

The invention belongs to the field of phosphorus based silane flame retardants, and particularly relates to a phosphorus based silane flame retardant and a preparing method thereof. According to the method, organosilicon oligomer and amino siloxane are used as raw materials, a mixed agent of a reaction auxiliary A and a reaction auxiliary B is used as a reaction auxiliary, and the phosphorus based silane flame retardant is obtained through a reaction, wherein the reaction auxiliary A is hydroxytrimethylsilane, hydroxytrimethylsilane salt or tetrakis(trimethylsilyl)silane, the reaction auxiliary B is hexamethyldisilazane or bis(trimethylsilyl)amide salt, and the molar ratio of the reaction auxiliary A to the reaction auxiliary B is (0.04-10):1. According to the phosphorus based silane flame retardant and the preparing method thereof, the synthesis cost of the phosphorus based silane flame retardant in the prior art is effectively lowered, the synthesis technology is simple, and the safety coefficient is high.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

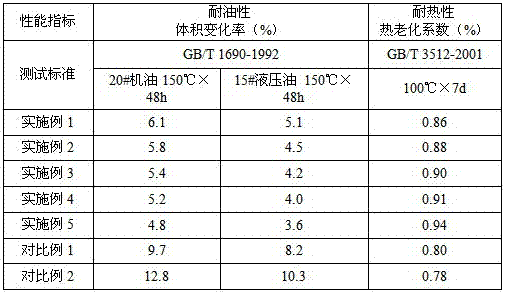

Oil-resistant and heat-resistant rubber material and preparation method thereof

The invention provides an oil-resistant and heat-resistant rubber material and a preparation method thereof. The preparation method is as follows: (1) preparing modified sodium hexatitanate whiskers; (2) weighing the following components by weight: 70-100 parts of nitrile rubber, 30-50 parts of silicone rubber, 4-7 parts of zinc oxide, 20-40 parts of carbon black, 2-4 parts of glycerin, 0.5-2.5 parts of zinc stearate, 5-12 parts of dioctyl phthalate, 2-4 parts of sulfur, 0.5-1.5 parts of accelerator M , accelerator TMTM is 0.5-1 part, anti-aging agent 4010NA is 0.5-1.5 parts, anti-aging agent AW is 0.5-1.2 parts, 2-ethyl zirconium acetate is 2-6 parts, potassium trimethylsiliconate is 2.5-5 parts, 3‑7 parts of modified sodium hexatitanate whiskers; (3) Rubber materials are prepared by banburying, then kneading, and vulcanization. The oil-resistant and heat-resistant rubber material of the invention has reasonable formula, simple process and good heat-resistant and oil-resistant properties.

Owner:苏州纳贝通环境科技有限公司

Method for preparing wood-plastic composite material by modified wood chips

The invention discloses a method for preparing a wood-plastic composite material by modified wood chips, belonging to the field of composite materials. The method comprises the steps that screening wood chips by water floating, premixing the screened wood chips with tetraethl silicate for reaction at high temperature, and performing high pressure and extrusion treatment on a mixture, then performing reaction on the mixture and the substances such as trimethylsilanol at high temperature to obtain the modified wood chips, mixing the modified wood chips with raw materials, extruding and pelletizing, so as to obtain the method for preparing the wood-plastic composite material by the modified wood chips. An example proves that the method disclosed by the invention is simple in preparation technology, strong in operability, timber resources are saved by utilizing the wood chips as a raw material, the advantages of a wood-plastic material such as green environmental protection and resources saving are maintained, the prepared wood-plastic composite material has strong aging resistance, good toughness, strong thermal conductivity, is difficult in brittle failure, and suitable for large-scale industrialization promotion.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Chloroprene rubber-based pressure sensitive tape and preparation method thereof

ActiveCN104109484AHigh viscosityGood application effectNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveTrimethylsilanolPolymer science

The invention discloses a chloroprene rubber-based pressure sensitive tape, which comprises the following components by weight ratio: 32-39 parts of chloroprene rubber, 17-22 parts of butadiene, 5-9 parts of polyvinyl methyl ether, 2-4 parts of diethylenetriamines, 6-10 parts of acrylonitrile, 4-7 parts of glyoxal and 5-6 parts of hydroxytrimethylsilane. A preparation method of the chloroprene rubber-based pressure sensitive tape comprises the following steps: 1)taking chloroprene rubber and butadiene, uniformly mixing chloroprene rubber and butadiene with stirring to obtain a mixture; 2)adding the mixture obtained in the step 1) in a mixing roll from a feed inlet, adding polyvinyl methyl ether, diethylenetriamines and acrylonitrile for mixing in the mixing roll from the feed inlet; 3)adding glyoxal and hydroxytrimethylsilane in the mixing roll and then mixing; and 4)cutting a chloroprene rubber-based pressure sensitive adhesive to obtain the pressure sensitive tape.

Owner:SUZHOU JINHE NEW MATERIAL

Brush wire of environmental sanitation brush and preparation method thereof

InactiveCN110592718AImprove wear resistanceExtend working lifeBristleConjugated cellulose/protein artificial filamentsFiberCarbon fibers

The invention discloses a brush wire of an environmental sanitation brush. The brush wire of the environmental sanitation brush is prepared from, 20-35 parts of polyamide resin, 15-28 parts of PP resin, 5-8 parts of thermosetting resin, 2-4 parts of carbon fibers, 10-23 parts of trimethylammonium methyl sulphate, 3-9 parts of ethyl cellulose, 2-6 parts of glass fibers, 8-16 parts of hydroxytrimethylsilane, 5-15 parts of fatty acid macrogol ester, 3-10 parts of a coupling agent, 2-5 parts of a plasticizer, 2-6 parts of a wear-resistant agent, 3-6 parts of an accelerant and 1-6 parts of an antioxidant. According to the brush wire of the environmental sanitation brush, the wear resistance and strength of the brush wire are improved, the service life of the brush wire under a harsh environmental condition is greatly prolonged, and when the brush wire is used for ground sweeping, the quality is high, the efficiency is high, and the wear resistance is strong; the processing cost is low, thequality is stable, the brush wire is not deformed, and the production and processing process is easy to control.

Owner:安徽鑫宏源刷业有限公司

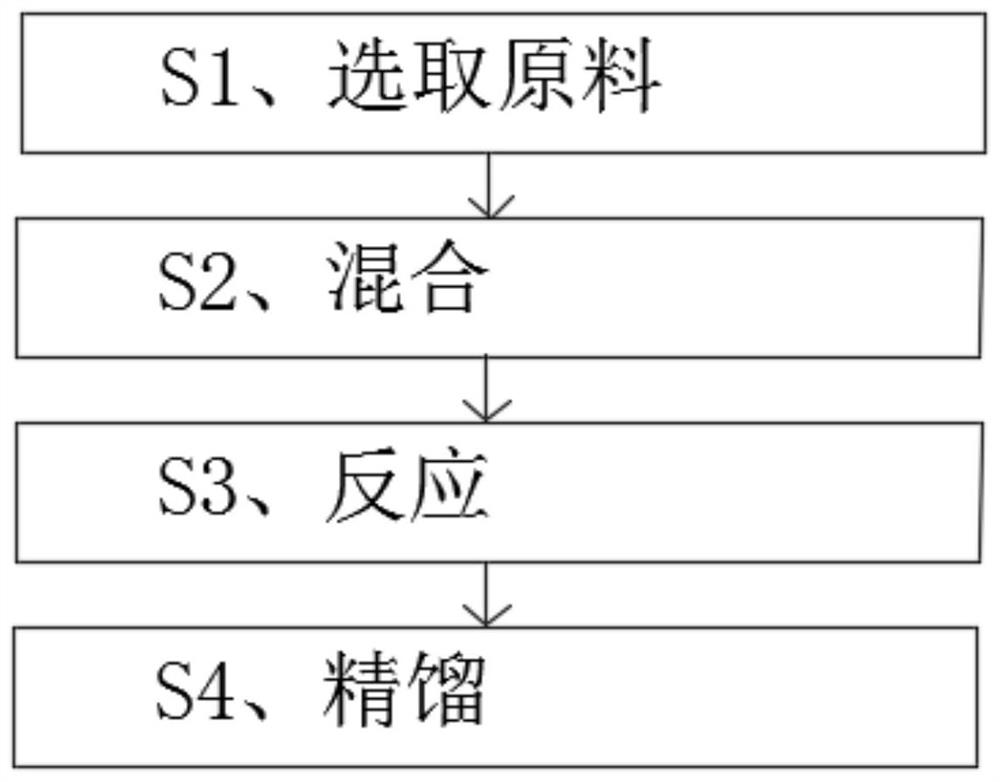

Preparation method of trimethylsilanol

PendingCN111808129ASimple production processFewer post-processing stepsSilicon organic compoundsTrimethylsilanolAcetic acid

The invention discloses a preparation method of trimethylsilanol. The preparation method is characterized by specifically comprising the following steps: S1, selecting raw materials: selecting, by weight for later use: 450-550 parts of hexamethyldisilazane, 45-55 parts of glacial acetic acid and 90-110 parts of water; S2, mixing: adding water and glacial acetic acid into a 1000 ml four-necked bottle, mixing, uniformly stirring, and then heating the mixed solution to 60-70 DEG C; S3, reacting: dropwise adding hexamethyldisilazane into the mixed solution obtained in step S2, and reacting for 2-3hours; and S4, rectifying: distilling a solution obtained in step S3 to obtain trimethylsilanol with the purity of 98% or above. The preparation method of the trimethylsilanol has the advantages of simple raw materials, short manufacturing process, less production waste and the like.

Owner:苏州矽索新材料有限公司

Improved concrete pumping agent

An improved concrete pumping agent is prepared from the following raw materials in parts by weight: 6-10 parts of aluminium sesquioxide, 3-9 parts of calcium lignosulphonate, 5-11 parts of hydroxypropyl starch ether, 5-8 parts of methyl cellulose, 2-7 parts of ammonium carbonate, 2-5 parts of an amine cosolvent, 6-9 parts of sodium alkylbenzenesulfonate, 7-11 parts of perfluorooctyl triethoxysilane, 2-4 parts of sulfur trioxide, 4-10 parts of nano silica, 4-10 parts of sodium trimethyl silanol, 1-5 parts of p-hydroxy N,N-dimethylcyclohexylamine, 3-8 parts of diethanol amine, 40 parts of water and 5-8 parts of silica powder. The improved concrete pumping agent has the benefits of being stable in performance, high in temperature applicability, wide in application range, and high in water reducing rate.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Environmental-friendly waterborne polyurethane coating

InactiveCN109370412AImprove tear resistanceHigh hardnessAntifouling/underwater paintsPaints with biocidesInorganic saltsTrimethylsilanol

The invention discloses an environmental-friendly waterborne polyurethane coating and relates to the technical field of waterborne coatings. The environmental-friendly waterborne polyurethane coatingis prepared from the following components: tetrasilanol sodium salt modified polyurethane emulsion, nano calcium carbonate, diatom ooze, hollow glass beads, potassium trimethylsilanolate, vinyl versatate, inorganic salt powder, a wetting agent, an antifoaming agent, a dispersing agent and a thickening agent. The environmental-friendly waterborne polyurethane coating prepared from the invention hasexcellent scrubbing resistance, stain resistance and artificial aging resistance.

Owner:含山县领创新材料科技有限公司

Preparation method of lithium trimethylsilanolate

ActiveCN102491993BEasy for industrial production and applicationRaw materials are cheap and easy to getGroup 4/14 element organic compoundsTrimethylsilanolLithium hydroxide

The invention relates to a preparation method of lithium trimethylsilanolate. According to the method, lithium trimethylsilanolate is prepared through reacting a lithium hydroxide raw material with hexamethyldisiloxane under the protection of N2 with waterless ethanol, methanol or butanol and cyclohexane as a mixed solvent. The method has the characteristics of simple synthetic process, cheap and easily available raw material, and low cost. Obtained lithium trimethylsilanolate is mainly used for initiating the ring-opening polymerisation of cyclotrisiloxane as an initiator to prepare block polysiloxanes or single-terminal function group polysiloxanes.

Owner:SHANDONG UNIV

Method for preparing composite molten steel heat preservation agent based on blast furnace slag

InactiveCN105950803AGood spreadabilityImprove insulation effectRecycling and recovery technologiesProcess efficiency improvementDistillationSlag

The invention relates to a method for preparing a composite molten steel heat preservation agent based on blast furnace slag and belongs to the technical field of heat preservation agent preparation. The method includes the steps that firstly, the blast furnace slag and hydrochloric acid are stirred and mixed; after impurities are removed, the obtained filter residues are calcined and cooled, and then the obtained filter residues are soaked in hydrogen peroxide and filtered; the obtained filter slag is mixed with a potassium permanganate solution and a platinum-titanium catalyst; after heat preservation and distillation are conducted, trimethyl silanol is added, and then heat preservation and distillation are conducted; distillation residues are collected, washed, dried and smashed, and a molten steel heat preservation substrate can be obtained; and finally the molten steel heat preservation substrate, calcium oxide and other matter are mixed and milled, and the composite molten steel heat preservation agent can be obtained. The composite molten steel heat preservation agent prepared through the method is good in spreadability, and the spreadability is larger than 94%; the composite molten steel heat preservation agent does not react with compositions in molten steel, the heat preservation effect is good, and the motel steel temperature drop is smaller than 0.2 DEG C / min; and the specific gravity is small, no molten steel spatters in the adding process, no dust flies around, and the environment is protected.

Owner:郭迎庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com