Biomass composite material with high hydrophobicity and preparation method thereof

A composite material and high hydrophobicity technology, applied in the field of composite materials, can solve problems such as cracking, deformation, and affecting material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

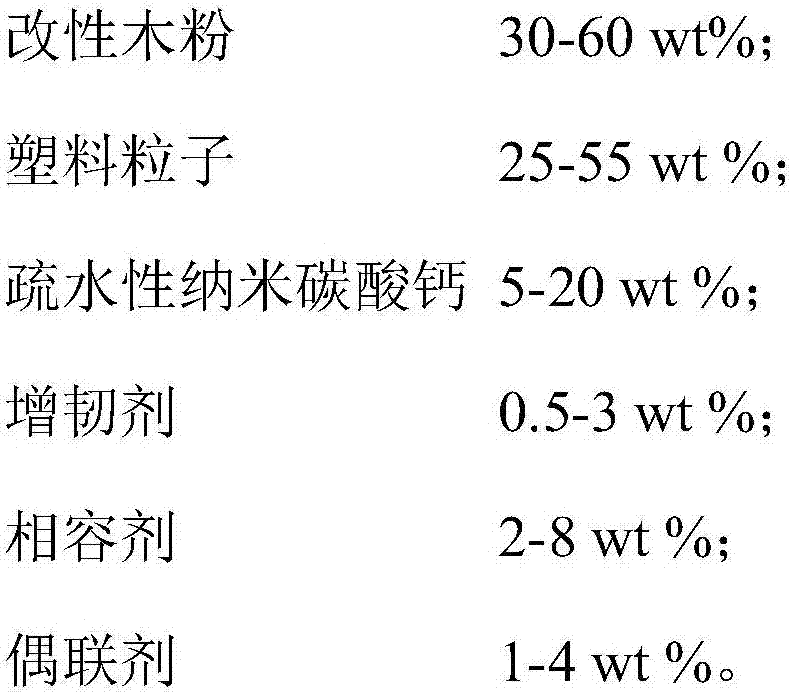

[0069] A kind of biomass composite material with high hydrophobicity, its raw material is composed of by weight:

[0070]

[0071] The plastic particles are PE particles with a molecular weight of 130,000;

[0072] Toughening agent is maleic anhydride grafted ethylene-vinyl acetate copolymer;

[0073] The antioxidant is antioxidant 1010;

[0074] The lubricant is polyethylene wax.

[0075] Concrete preparation is carried out according to the following steps:

[0076] A. Raise the temperature of modified wood flour, plastic particles, hydrophobic nano-calcium carbonate and other raw materials to 140°C, mix them well and discharge them into the cold mixing machine, then cool them down to 70°C and discharge them to make a special premix.

[0077] B. The above-mentioned special premix is added to a parallel twin-screw extruder to extrude and granulate; the process conditions are: the barrel temperature is 150-190°C, and the screw speed is 200-300rpm;

[0078] C, putting t...

Embodiment 2

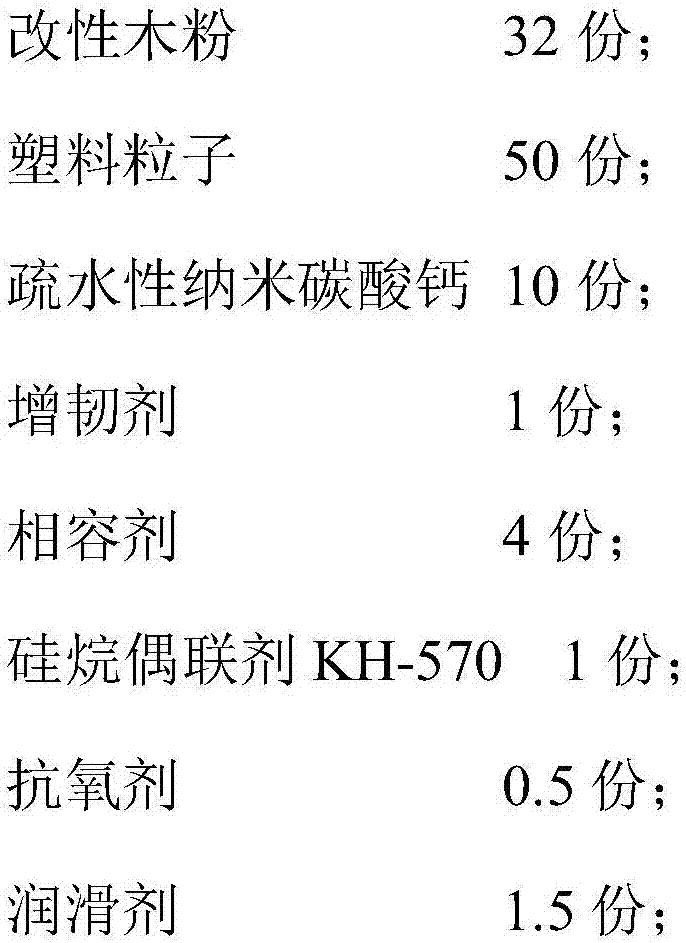

[0081] A kind of biomass composite material with high hydrophobicity, its raw material is composed of by weight:

[0082]

[0083] The plastic particles are PE particles with a molecular weight of 100,000;

[0084] The toughening agent is solid polysulfide rubber;

[0085] The antioxidant is antioxidant 1010;

[0086] The lubricant is polyethylene wax.

[0087] Prepare according to the preparation method of the embodiment.

Embodiment 3

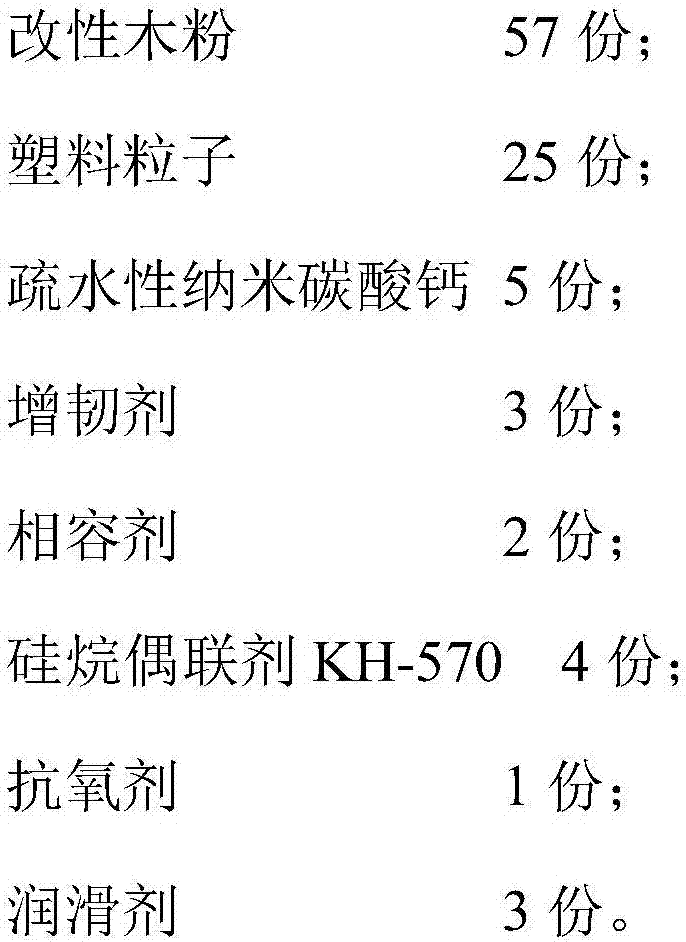

[0089] A kind of biomass composite material with high hydrophobicity, its raw material is composed of by weight:

[0090]

[0091] The plastic particles are HDPE particles with a molecular weight of 130,000;

[0092] Toughening agent is maleic anhydride grafted ethylene-vinyl acetate copolymer;

[0093] The antioxidant is antioxidant 1010;

[0094] The lubricant is solid chlorinated paraffin 70.

[0095] Prepare according to the preparation method of the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com