Preparing method of phosphorus based silane flame retardant

A technology of flame retardant and silane, applied in the field of preparation of phosphorus-based silane flame retardant, can solve the problems of high cost, unfavorable personal safety of experimenters, long reaction period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

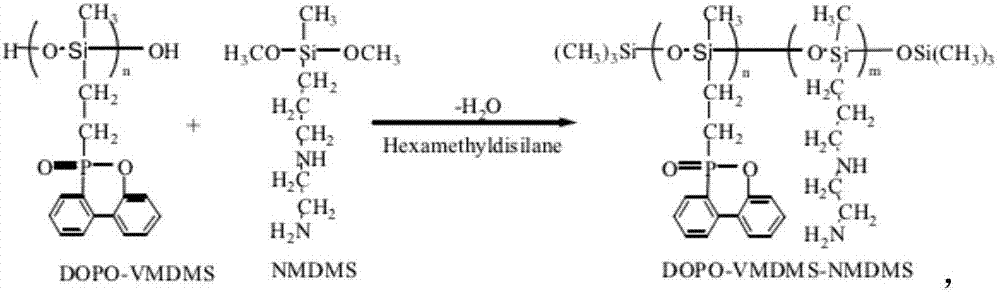

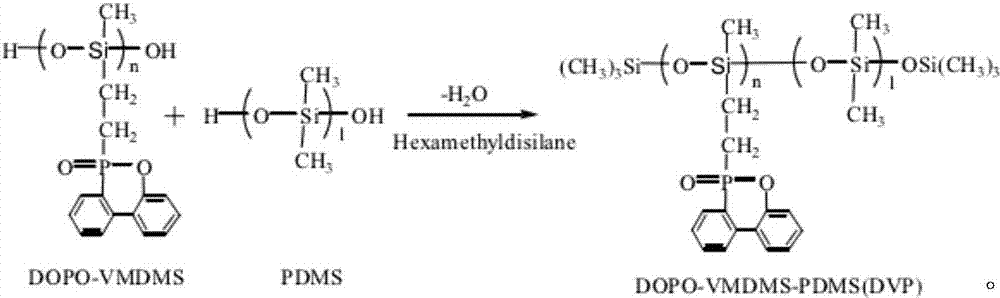

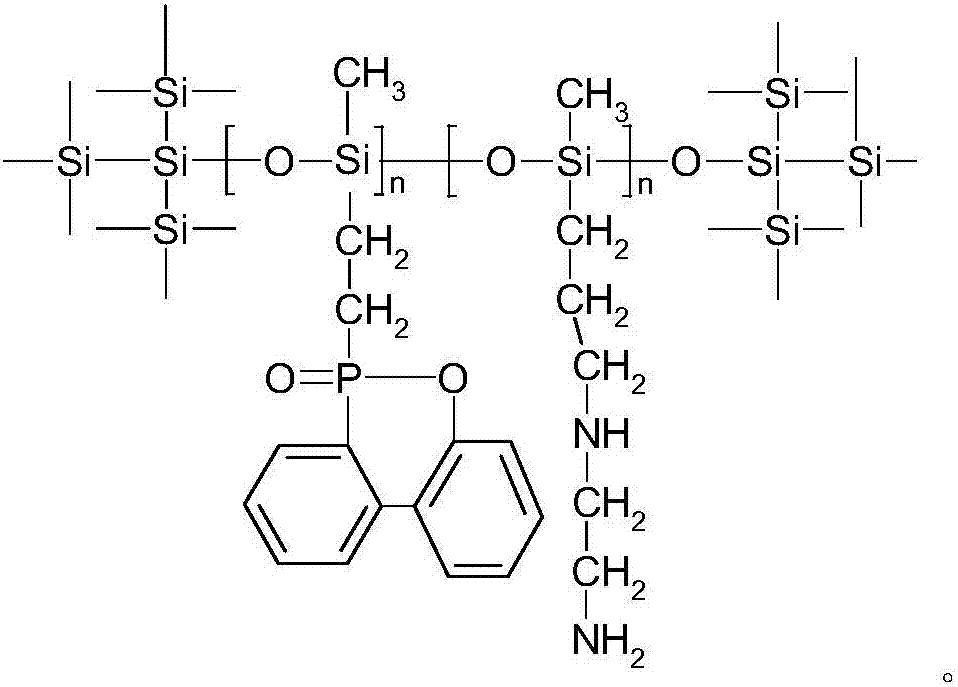

[0022] A preparation method of a phosphorus-based silane flame retardant, using organosilicon oligomers and aminosiloxanes as raw materials, and using a mixture of reaction auxiliary agent A and reaction auxiliary agent B as a reaction auxiliary agent, and reacting to obtain phosphorus-based silane flame retardants. Combustion agent; Wherein, reaction auxiliary agent A is trimethylsilanol, trimethylsiliconate or tetrakis (trimethylsilyl) silane; Reaction auxiliary agent B is hexamethyldisilazane or bis(trimethylsilazane) Silicon base) amino salt; the molar ratio of reaction auxiliary agent A to reaction auxiliary agent B is (0.04-10):1. Wherein the trimethylsiliconate is sodium trimethylsiliconate, potassium trimethylsiliconate or lithium trimethylsiliconate. The bis(trimethylsilyl)amide salt is sodium bis(trimethylsilyl)amide, lithium bis(trimethylsilyl)amide or potassium bis(trimethylsilyl)amide.

[0023] Preferably, the reaction temperature of the silicone oligomer and ami...

Embodiment 1

[0028] Preparation of DVN

[0029] In a 500ml three-neck round bottom flask, 5mol of organosilicon oligomer (DOPO-VMDMS) and 10mol of aminosiloxane (NMDMS) were added in different proportions. First add 0.25mol trimethylsilanol, then slowly add 0.5mol bis(trimethylsilyl) lithium amide, continue to stir and react for 12 hours, carry out classification filtration to the reaction system according to molecular weight, obtain unreacted raw materials, Lithium salt, water, a small amount of lithium bis(trimethylsilyl)amide, and DVN; DVN is a slightly yellow translucent solid at room temperature, and the yield is about 96%. The reaction temperature was 35°C.

[0030] Reaction phenomenon: During the reaction process, before the addition of bis(trimethylsilyl)amide lithium, there is no change, and when bis(trimethylsilyl)amide lithium is added, heat is gradually generated, and the color of the reaction solution gradually turns yellow.

[0031] Wherein, in this embodiment, the reaction...

Embodiment 2

[0034] The difference from the example is that 0.25 mol of trimethylsilanol is replaced by 0.25 mol of trimethylsiliconate. In this embodiment, when trimethylsiliconate is used, the molar ratio of trimethylsiliconate to lithium bis(trimethylsilyl)amide is (0.1-10):1. DVN yield was 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com