Efficient flame retardant siloxy fluoro cyclotriphosphazene and synthesis method thereof

A technology of siloxy fluoro cyclotriphosphazene and fluoro cyclotriphosphazene, which is applied in the field of high-efficiency flame retardant siloxy fluoro cyclotriphosphazene and its synthesis, can solve the problem of not being able to completely prevent battery fire, Combustion or even explosion, inability to significantly improve the flash point of lithium-ion battery electrolyte, negative impact on lithium battery performance, etc., to improve battery capacity retention, facilitate industrial production, and improve cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

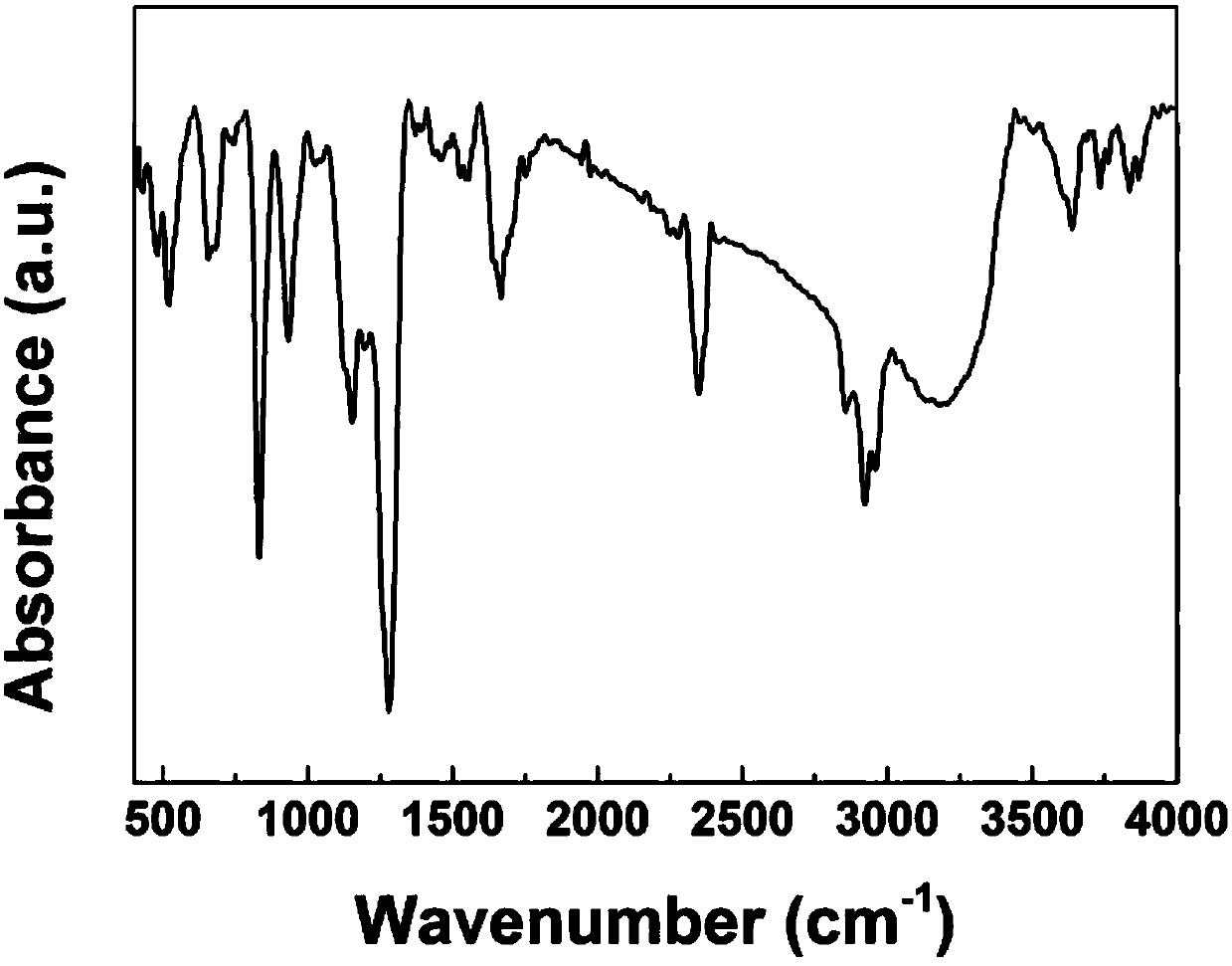

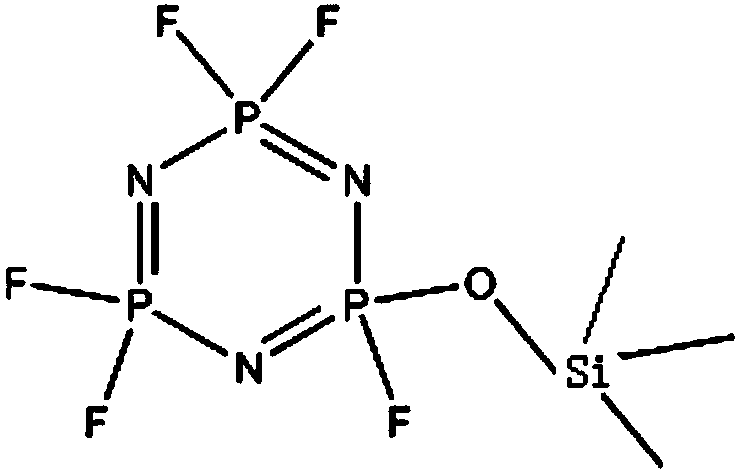

[0033] Dissolve 49.8g of hexafluorocyclotriphosphazene crystals in 200ml of tetrahydrofuran to form a hexafluorocyclotriphosphazene solution. Add 12.9g of potassium trimethylsiloxide to the solution, stir until uniform, and react at 10°C for 20h , After filtration and vacuum distillation, the phosphonitrile derivative siloxy fluorocyclotriphosphazene is obtained, which has the following structural formula:

[0034] The yield is 95%, and infrared is used to determine its structure, such as figure 1 Shown.

Embodiment 2

[0036] 49.8g of hexafluorocyclotriphosphazene crystals are dissolved in 300ml of n-hexane to form a hexafluorocyclotriphosphazene solution. Add 12.9g of potassium trimethylsiloxide to the solution, stir until uniform, and react for 10h at 40℃ After filtering and distillation under reduced pressure, the phosphonitrile derivative siloxy fluorocyclotriphosphazene is obtained with a yield of 96%.

Embodiment 3

[0038] 49.8g of hexafluorocyclotriphosphazene crystals are dissolved in 200ml of chlorobenzene to form a hexafluorocyclotriphosphazene solution. Add 12.9g of potassium trimethylsiloxide to the solution, stir until uniform, and react at 30°C After 15 hours, the phosphonitrile derivative siloxy fluorocyclotriphosphazene was obtained after filtration and distillation under reduced pressure with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com