Preparation method of MQ branched-chain modified silicon resin polymer for large-scale integrated circuit package

A technology of large-scale integrated circuit and MQ silicone resin, which is applied in the field of preparation of MQ branched modified silicone resin polymer in large-scale integrated circuit packaging, can solve the problems of poor tensile strength, impact strength and bonding performance, and achieves The effect of excellent weather resistance and electrical properties, low thermal conductivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

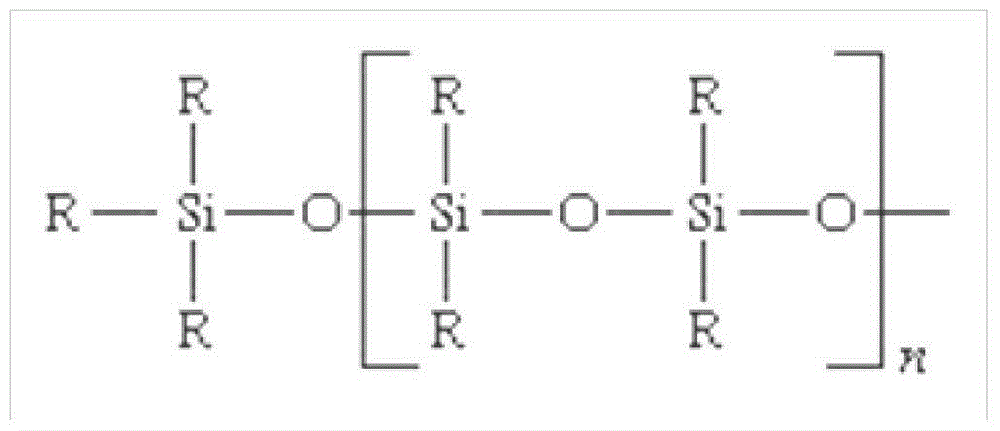

[0027] In terms of parts by mass, take 70 parts of α,ω-dihydroxy polydimethylsiloxane with a degree of polymerization of 10 and 30 parts of methylvinyl MQ silicone resin with an M / Q value of 0.7 and a vinyl content of 3.0%. (Linear polymer A) was put into the reactor, started to stir for 25 minutes, the rotation speed was 75 rpm, the temperature was raised to 90°C, and the heating rate was 2°C / min; 0.03% by mass of dihydroxy polydimethylsiloxane was added to potassium trimethylsiliconate as a catalyst, and stirred at a constant temperature for 2.5 hours. After the reactant became a transparent colloid, the heating was stopped, and the stirring was continued until it was cooled to room temperature, and the product 1 was obtained. , and various performance tests were carried out on the product, and the test results are shown in Table 1:

[0028] Table 1 Main performance indicators of product 1

[0029] Performance name

Embodiment 2

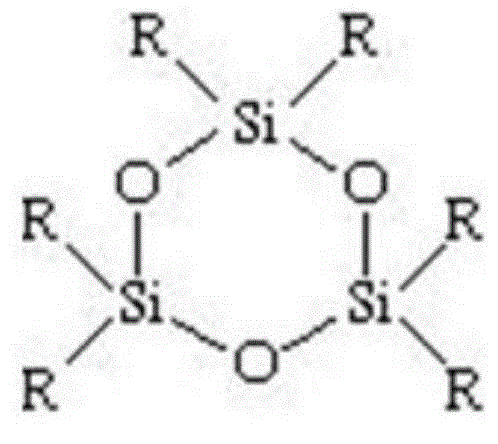

[0031] According to the number of parts by mass, take 80 parts of α, ω-hydroxypoly(dimethyl-methylvinyl) siloxane with a degree of polymerization of 15 and 20 parts of methyl MQ silicone resin (cyclic polymer B) into the reaction Kettle, start and stir for 35 minutes, the speed is 80 rpm, the temperature is raised to 85°C, and the heating rate is 2°C / min; after the system is mixed uniformly and the temperature is stable, according to the 0.02% by mass of vinyl) siloxane was added potassium trimethylsiliconate as a catalyst, stirred at constant temperature for 1.5 hours, stopped heating after the reactant turned into a transparent colloid, and continued to stir until cooled to room temperature to obtain product 2. And various performance tests were carried out on the product, and the test results are shown in Table 2:

[0032] Table 2 Main performance indicators of product 2

[0033] Performance name

Embodiment 3

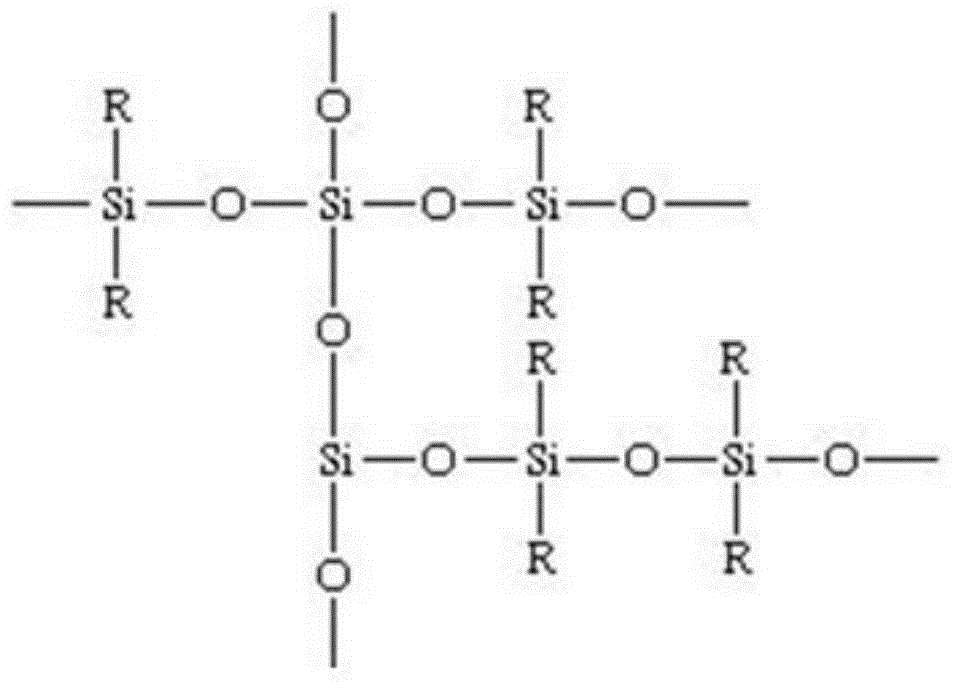

[0035] According to the number of parts by mass, take 85 parts of α, ω-dihydroxy polydimethylsiloxane with a degree of polymerization of 20 and 15 parts of methyl vinyl MQ silicone resin with an M / Q value of 0.7 (cross-linked polymer C) Put it into the reaction kettle, start stirring for 35 minutes, the speed is 60 rpm, the temperature is raised to 95°C, and the heating rate is 2°C / min; after the system is uniformly mixed and the temperature is stable, according to the 0.04% by mass of siloxane was added with sodium trimethylsiliconate as a catalyst, stirred at a constant temperature for 3 hours, stopped heating after the reactant turned into a transparent colloid, and continued to stir until cooled to room temperature to obtain product 3. And various performance tests were carried out on the product, and the test results are shown in Table 3:

[0036] Table 3 Main performance indicators of product 3

[0037] Performance name

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com