Oil-resistant and heat-resistant rubber material and preparation method thereof

A heat-resistant rubber and oil-resistant technology, applied in the field of oil-resistant and heat-resistant rubber materials and their preparation, can solve the problems of high cost and complicated operation, and achieve the effects of stable performance, high thermal aging coefficient and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

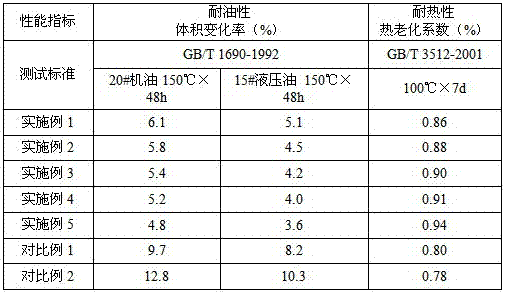

Examples

Embodiment 1

[0016] A method for preparing an oil-resistant and heat-resistant rubber material, comprising the following steps: (1) Prepare sodium hexatitanate whiskers into an aqueous solution with a concentration of 10wt%, disperse evenly, heat the water bath to 75°C, and then add 6wt% Sodium silicate solution, insulated for 5h, filtered, washed and dried to obtain coated SiO 2 The sodium hexatitanate whisker; (2) the silane coupling agent KH-570 and coated SiO 2 The sodium hexatitanate whiskers were added to the ethanol solution with a concentration of 80wt%, the mass ratio of the three was 3:100:500, ultrasonically dispersed for 15 minutes, stirred at a constant temperature of 70°C for 20 minutes, filtered, washed and dried to obtain modified sodium hexatitanate (3) Weigh the following ingredients by weight: 70 parts of nitrile rubber, 50 parts of silicone rubber, 4 parts of zinc oxide, 20 parts of carbon black, 4 parts of glycerol, 0.5 parts of zinc stearate, phthalate 5 parts of dio...

Embodiment 2

[0018] A method for preparing an oil-resistant and heat-resistant rubber material, comprising the following steps: (1) Prepare sodium hexatitanate whiskers into an aqueous solution with a concentration of 18wt%, disperse evenly, heat the water bath to 75°C, and then add 3wt% sodium hexatitanate whiskers Sodium silicate solution, insulated for 5h, filtered, washed and dried to obtain coated SiO 2 The sodium hexatitanate whisker; (2) the silane coupling agent KH-570 and coated SiO 2 The sodium hexatitanate whiskers were added to the ethanol solution with a concentration of 95wt%, the mass ratio of the three was 3:100:500, ultrasonically dispersed for 5 minutes, stirred at a constant temperature of 70°C for 35 minutes, filtered, washed and dried to obtain modified sodium hexatitanate (3) Weigh the following ingredients by weight: 100 parts of nitrile rubber, 30 parts of silicone rubber, 7 parts of zinc oxide, 40 parts of carbon black, 2 parts of glycerol, 2.5 parts of zinc steara...

Embodiment 3

[0020] A method for preparing an oil-resistant and heat-resistant rubber material, comprising the following steps: (1) Prepare sodium hexatitanate whiskers into an aqueous solution with a concentration of 15wt%, disperse evenly, heat the water bath to 75°C, and then add Sodium silicate solution, insulated for 5h, filtered, washed and dried to obtain coated SiO 2 The sodium hexatitanate whisker; (2) the silane coupling agent KH-570 and coated SiO 2 The sodium hexatitanate whiskers were added to the ethanol solution with a concentration of 85wt%, the mass ratio of the three was 3:100:500, ultrasonically dispersed for 10 minutes, stirred at a constant temperature of 70°C for 25 minutes, filtered, washed and dried to obtain modified sodium hexatitanate (3) Weigh the following ingredients by weight: 80 parts of nitrile rubber, 45 parts of silicon rubber, 6 parts of zinc oxide, 25 parts of carbon black, 4 parts of glycerol, 2 parts of zinc stearate, phthalate 6 parts of dioctyl dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com