Direct-current power-driven vacuum pump used for automobile

An electric vacuum pump, direct current technology, applied in the direction of pumps, machines/engines, rotary piston pumps, etc., can solve the problems of unfavorable miniaturization design of cars, enlarged vacuum pump structure, long vacuuming time, etc. The effect of low resistance and short vacuuming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

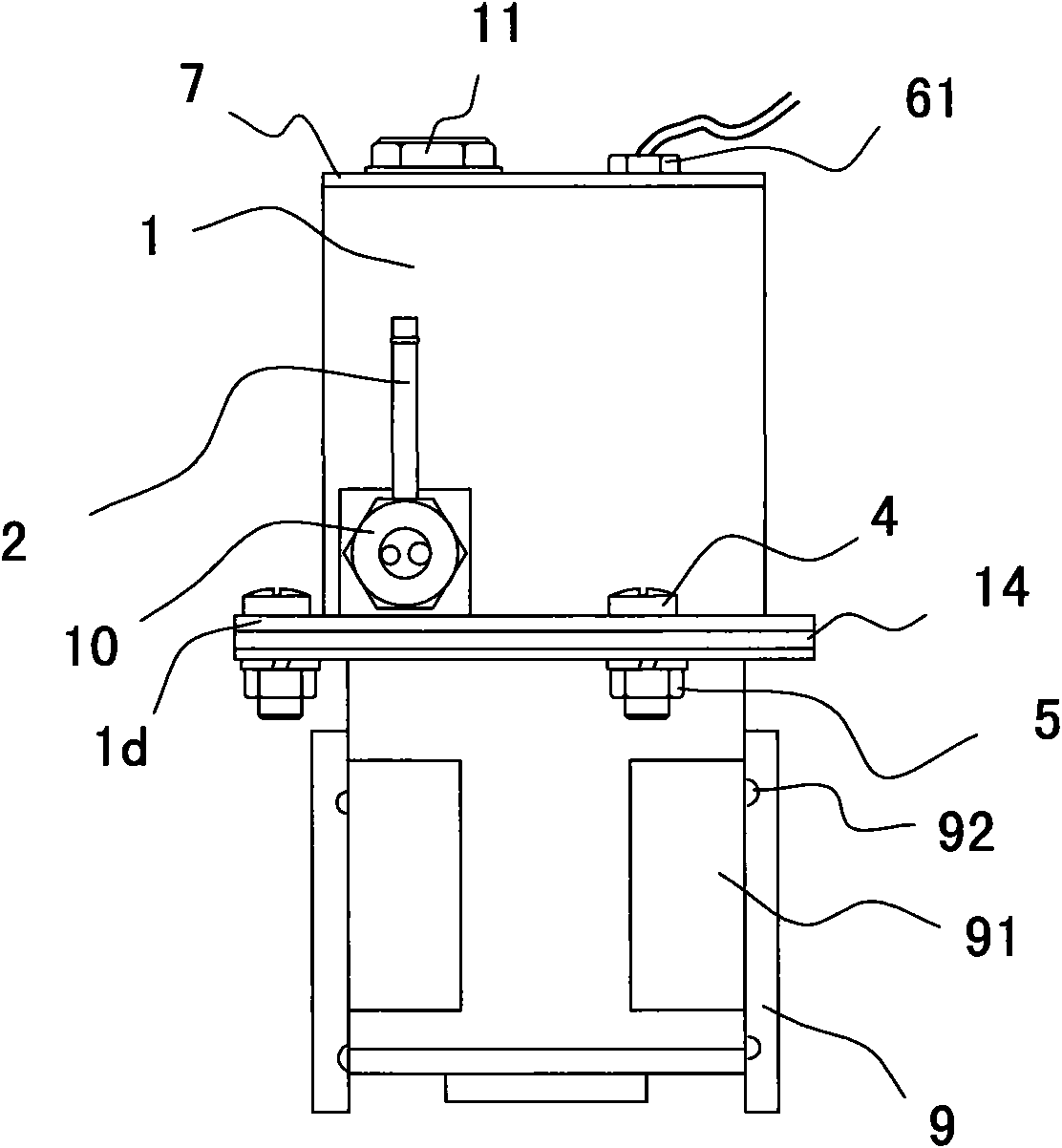

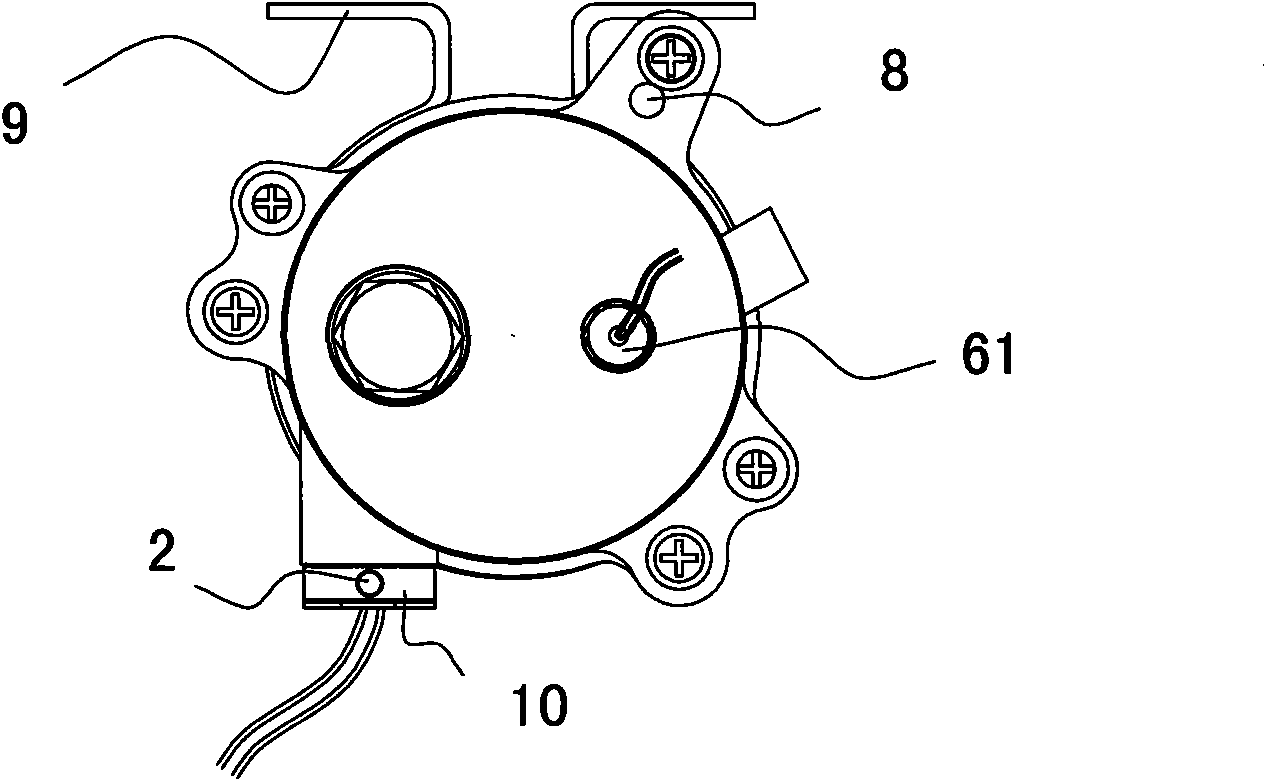

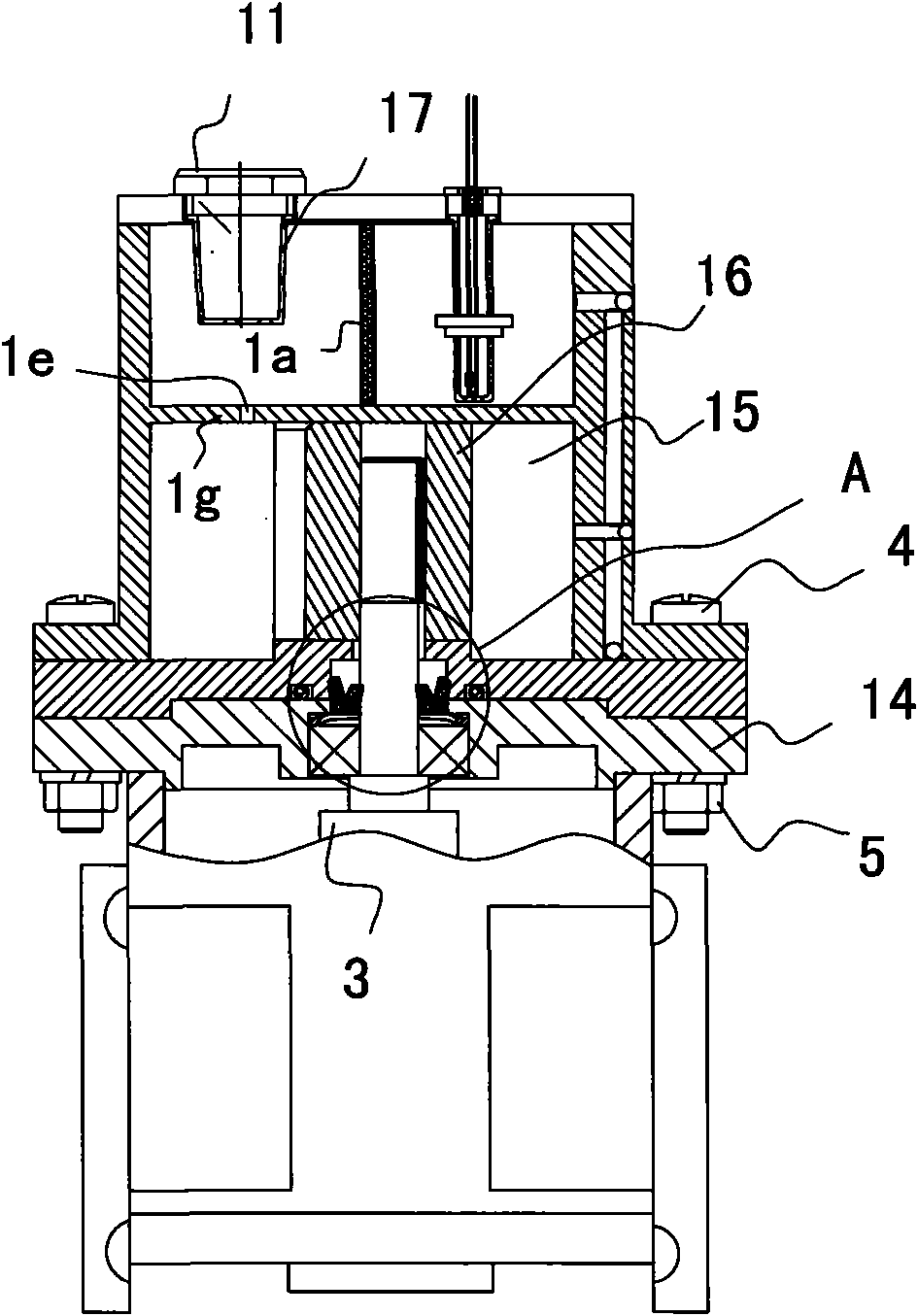

[0019] see figure 1 , and combined with figure 2 . Viewed from the outside, the vacuum pump consists of a pump body and a DC motor 3 from top to bottom. The pump body is composed of a split pump body cover 7, a pump body wall 1 and a lower casing 14, wherein the pump body cover 7 and the pump body wall 1 form an upper casing. The circumference of the circular pump body cover 7 is surrounded by several fixed through holes, which are matched with it. The upper end surface of the pump body wall 1 is provided with threaded connection sink holes, and the pump body cover 7 and the pump body wall 1 are connected by bolts. into a whole. The pump body cover 7 is also provided with a filter screen installation hole 71 and a liquid level sensor installation hole 72 , and these two holes are used to receive the muffler 11 and the installation nut 61 .

[0020] The DC motor 3, the lower casing 14 and the pump body wall 1 pass through the mounting flange 1d at the lower end of the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com